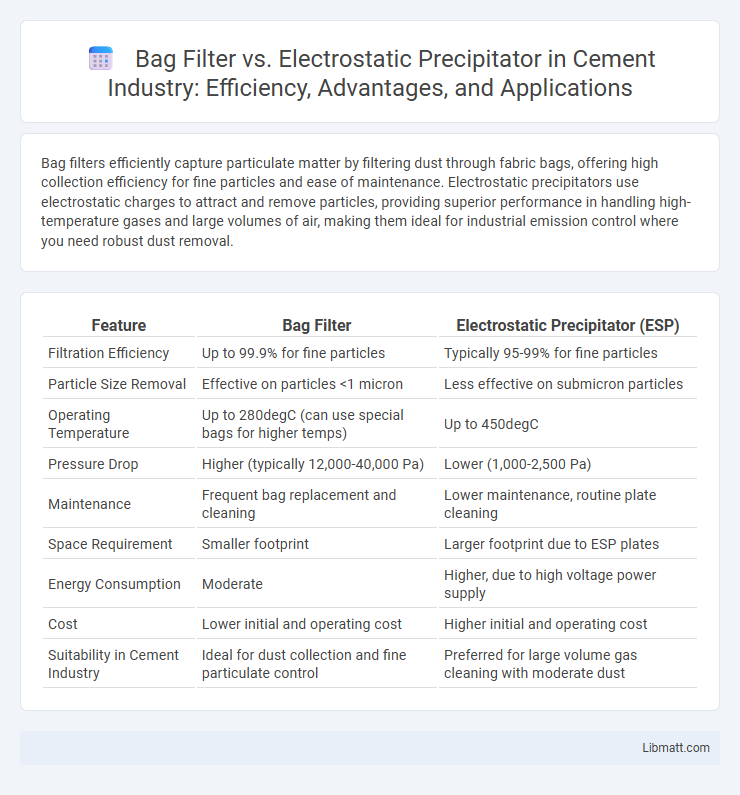

Bag filters efficiently capture particulate matter by filtering dust through fabric bags, offering high collection efficiency for fine particles and ease of maintenance. Electrostatic precipitators use electrostatic charges to attract and remove particles, providing superior performance in handling high-temperature gases and large volumes of air, making them ideal for industrial emission control where you need robust dust removal.

Table of Comparison

| Feature | Bag Filter | Electrostatic Precipitator (ESP) |

|---|---|---|

| Filtration Efficiency | Up to 99.9% for fine particles | Typically 95-99% for fine particles |

| Particle Size Removal | Effective on particles <1 micron | Less effective on submicron particles |

| Operating Temperature | Up to 280degC (can use special bags for higher temps) | Up to 450degC |

| Pressure Drop | Higher (typically 12,000-40,000 Pa) | Lower (1,000-2,500 Pa) |

| Maintenance | Frequent bag replacement and cleaning | Lower maintenance, routine plate cleaning |

| Space Requirement | Smaller footprint | Larger footprint due to ESP plates |

| Energy Consumption | Moderate | Higher, due to high voltage power supply |

| Cost | Lower initial and operating cost | Higher initial and operating cost |

| Suitability in Cement Industry | Ideal for dust collection and fine particulate control | Preferred for large volume gas cleaning with moderate dust |

Introduction to Air Pollution Control Technologies

Bag filters and electrostatic precipitators are essential air pollution control technologies used to capture particulate matter from industrial emissions. Bag filters utilize fabric bags to mechanically trap particles, achieving high collection efficiency for a wide range of particle sizes. Electrostatic precipitators employ electrical charges to remove fine particles and aerosols, optimizing your facility's compliance with air quality standards while minimizing pressure drop and operational costs.

Overview of Bag Filters

Bag filters are air pollution control devices that use fabric filter bags to capture particulate matter from industrial exhaust streams. They offer high filtration efficiency, often exceeding 99%, and are effective in removing fine dust particles and aerosols. Commonly applied in industries like cement, steel, and pharmaceuticals, bag filters provide reliable dust collection with low operational costs and easy maintenance.

Overview of Electrostatic Precipitators

Electrostatic precipitators (ESPs) are air pollution control devices that use electrical charges to remove fine particulate matter from industrial exhaust streams. By applying a high-voltage electrostatic field, the particles become charged and are attracted to oppositely charged collection plates, effectively reducing particulate emissions. Your choice between bag filters and ESPs depends on factors like particle size, moisture content, and operational temperatures, with ESPs excelling in handling large gas volumes and dry particulates.

Working Principles: Bag Filter vs Electrostatic Precipitator

Bag filters operate by physically trapping particulate matter on fabric filter bags as contaminated air passes through, capturing particles with high efficiency due to mechanical filtration. Electrostatic precipitators remove particles by imparting an electric charge to dust and pollutants, which are then attracted to and collected on oppositely charged plates or electrodes. Understanding these differing working principles helps you select the most suitable air pollution control device based on your specific industrial needs and particle types.

Particle Removal Efficiency Comparison

Bag filters achieve particle removal efficiencies exceeding 99.9% for fine particulate matter, particularly effective for particles larger than 1 micron due to mechanical filtration through fabric media. Electrostatic precipitators (ESPs) typically offer removal efficiencies ranging from 85% to 99% depending on particle size and operating conditions, excelling with smaller particles by charging and collecting them on plates. The choice between bag filters and ESPs hinges on specific particle size distributions, with bag filters preferred for consistent high-efficiency capture of micron-sized dust and ESPs favored for lower resistance and handling large gas volumes with a focus on submicron particles.

Installation and Operational Costs

Bag filters generally have lower initial installation costs compared to electrostatic precipitators but incur higher operational expenses due to frequent bag replacement and maintenance. Electrostatic precipitators require a significant upfront investment for installation and setup, including high-voltage power supplies and complex control systems, yet offer lower ongoing operational costs with minimal consumables. The choice between these technologies depends on budget constraints, emission control requirements, and maintenance capacity.

Maintenance Requirements and Longevity

Bag filters require regular replacement of filter bags and frequent cleaning to maintain optimal efficiency, as accumulated dust hinders airflow. Electrostatic precipitators have lower maintenance due to fewer moving parts but need periodic inspection of high-voltage components and electrode cleaning to prevent performance degradation. Your choice depends on balancing the maintenance schedule with desired equipment longevity, as bag filters typically have shorter lifespans compared to the more durable electrostatic precipitators.

Applicability Across Different Industries

Bag filters effectively remove particulate matter in industries with high dust loads like cement, steel, and pharmaceuticals, where capturing fine particles is critical. Electrostatic precipitators excel in power plants, petrochemical, and pulp and paper industries by efficiently handling large gas volumes with low-resistance particles such as fly ash. Selection depends on particle characteristics, gas volume, temperature, and industry-specific emission standards.

Environmental and Regulatory Considerations

Bag filters provide superior particulate removal efficiency, often exceeding 99%, making them highly effective for meeting stringent environmental regulations on fine dust emissions. Electrostatic precipitators (ESPs) are energy-efficient for capturing large volumes of particles but may struggle with submicron particles, potentially impacting compliance with tightening air quality standards. Your choice should consider local regulatory limits, as bag filters often better accommodate evolving emission control requirements imposed by environmental agencies.

Choosing the Right Technology for Your Facility

Selecting between a bag filter and an electrostatic precipitator (ESP) depends on factors such as particle size, emission standards, and operational costs. Bag filters offer high efficiency for fine particles and are suitable for facilities with stringent particulate matter limits, while ESPs excel in handling large gas volumes and high-temperature conditions. Evaluating maintenance requirements, space constraints, and energy consumption is crucial to determining the most cost-effective and performance-optimized solution for your facility.

Bag filter vs Electrostatic precipitator Infographic

libmatt.com

libmatt.com