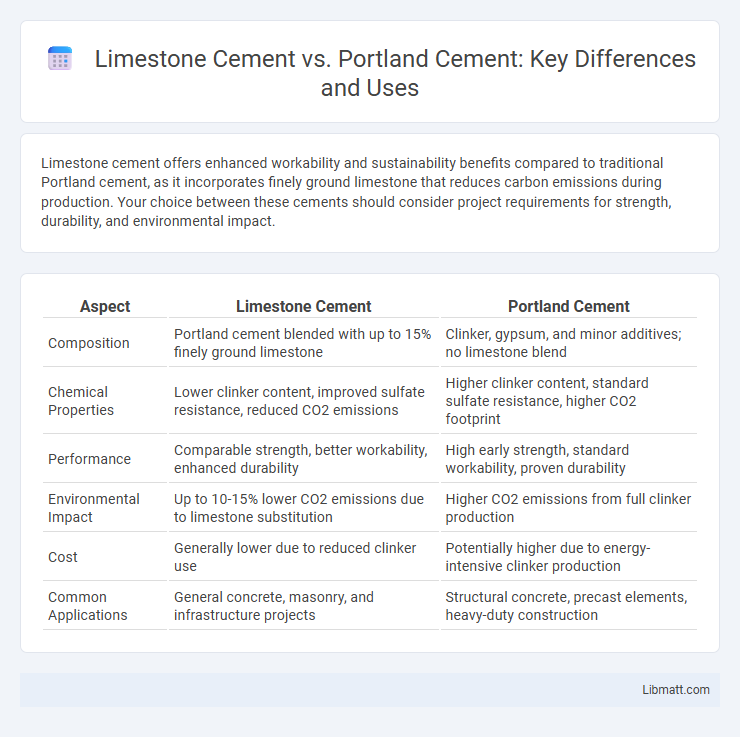

Limestone cement offers enhanced workability and sustainability benefits compared to traditional Portland cement, as it incorporates finely ground limestone that reduces carbon emissions during production. Your choice between these cements should consider project requirements for strength, durability, and environmental impact.

Table of Comparison

| Aspect | Limestone Cement | Portland Cement |

|---|---|---|

| Composition | Portland cement blended with up to 15% finely ground limestone | Clinker, gypsum, and minor additives; no limestone blend |

| Chemical Properties | Lower clinker content, improved sulfate resistance, reduced CO2 emissions | Higher clinker content, standard sulfate resistance, higher CO2 footprint |

| Performance | Comparable strength, better workability, enhanced durability | High early strength, standard workability, proven durability |

| Environmental Impact | Up to 10-15% lower CO2 emissions due to limestone substitution | Higher CO2 emissions from full clinker production |

| Cost | Generally lower due to reduced clinker use | Potentially higher due to energy-intensive clinker production |

| Common Applications | General concrete, masonry, and infrastructure projects | Structural concrete, precast elements, heavy-duty construction |

Introduction to Limestone Cement and Portland Cement

Limestone cement is a blended product consisting of Portland cement clinker mixed with finely ground limestone, typically containing around 5-15% limestone by weight, which enhances workability and sustainability by reducing clinker content. Portland cement, the most widely used hydraulic cement, is primarily composed of clinker minerals such as alite, belite, and gypsum, providing high early strength and durability for concrete construction. Both cements are essential in the construction industry, with limestone cement offering an eco-friendly alternative due to lower carbon emissions during production.

Composition and Material Differences

Limestone cement primarily consists of Portland cement blended with finely ground natural limestone, which acts as a supplementary cementitious material improving workability and reducing carbon footprint. Portland cement is mainly composed of clinker phases such as alite, belite, aluminate, and ferrite, formed by calcining limestone and other raw materials at high temperatures. Understanding these composition differences can help you select the best cement type for your construction needs based on performance and sustainability goals.

Manufacturing Processes Compared

Limestone cement manufacturing incorporates finely ground limestone with clinker during the final grinding stage, reducing energy consumption by up to 20% compared to Portland cement production, which involves clinkering limestone and clay at high temperatures around 1450degC. Portland cement manufacturing requires a calcination process followed by clinker cooling and grinding, resulting in higher CO2 emissions due to the decomposition of limestone and combustion of fossil fuels. Limestone cement's process optimization supports sustainability goals by lowering carbon footprint while maintaining comparable strength and durability characteristics.

Environmental Impact and Sustainability

Limestone cement reduces carbon emissions by incorporating finely ground limestone, which requires less energy to produce compared to traditional Portland cement, significantly lowering your project's carbon footprint. Portland cement production involves high-temperature calcination of limestone, releasing substantial CO2, making it less sustainable. Utilizing limestone cement supports sustainability goals by conserving natural resources and improving energy efficiency in construction.

Mechanical Properties and Strength

Limestone cement offers improved workability and reduced shrinkage compared to traditional Portland cement, enhancing durability in certain construction applications. Its mechanical properties include slightly lower compressive strength but better flexural strength, making it ideal for projects where flexibility and resistance to cracking are important. Understanding these differences helps you select the optimal cement type to achieve the desired balance of strength and performance in your construction project.

Durability and Longevity

Limestone cement exhibits enhanced durability due to its lower clinker content, which reduces the risk of cracking and shrinkage over time compared to traditional Portland cement. Portland cement, known for its high strength, can be more susceptible to chemical attack and sulfate exposure, potentially compromising longevity in harsh environments. The balanced composition of limestone cement improves resistance to weathering and enhances the overall lifespan of concrete structures in diverse conditions.

Applications and Use Cases

Limestone cement offers enhanced sustainability and reduced carbon emissions, making it ideal for residential buildings, low- to medium-strength concrete structures, and infrastructure projects such as pavements and bridges. Portland cement, known for its high strength and durability, is preferred in heavy-duty applications, including high-rise buildings, marine structures, and critical industrial constructions. Both cements are chosen based on specific performance requirements, environmental considerations, and cost-efficiency in construction projects.

Cost Comparison and Economic Benefits

Limestone cement typically costs 10-20% less than Portland cement due to lower energy requirements and raw material expenses, offering significant savings for large construction projects. The economic benefits of limestone cement include reduced carbon emissions and potential eligibility for green building incentives, which can enhance your project's sustainability profile and decrease overall operational costs. Choosing limestone cement can improve budget efficiency without compromising structural integrity or performance in most applications.

Performance in Different Climates

Limestone cement offers enhanced durability in various climates due to its improved resistance to sulfate attack and lower permeability, making it ideal for coastal and humid environments. Portland cement performs well in dry, temperate conditions but can be more susceptible to chemical degradation and cracking in freeze-thaw cycles or high sulfate soils. Your choice between limestone and Portland cement should consider the specific climate challenges to ensure long-lasting structural integrity.

Future Trends in Cement Technology

Limestone cement is gaining traction due to its lower carbon footprint and potential for sustainable construction compared to traditional Portland cement, which remains the industry standard. Advances in nanotechnology and alternative clinker materials are driving improvements in strength and durability for both cements. Emerging trends emphasize eco-friendly formulations and carbon capture integration to meet global emissions targets in cement production.

Limestone Cement vs Portland Cement Infographic

libmatt.com

libmatt.com