Turbine classifiers adapt to changing data patterns by dynamically adjusting their parameters, improving accuracy in real-time streaming applications, while static classifiers rely on a fixed model trained on a set dataset, making them less flexible but often faster in stable environments. Choosing the right classifier impacts your machine learning project's performance based on data variability and computational resources.

Table of Comparison

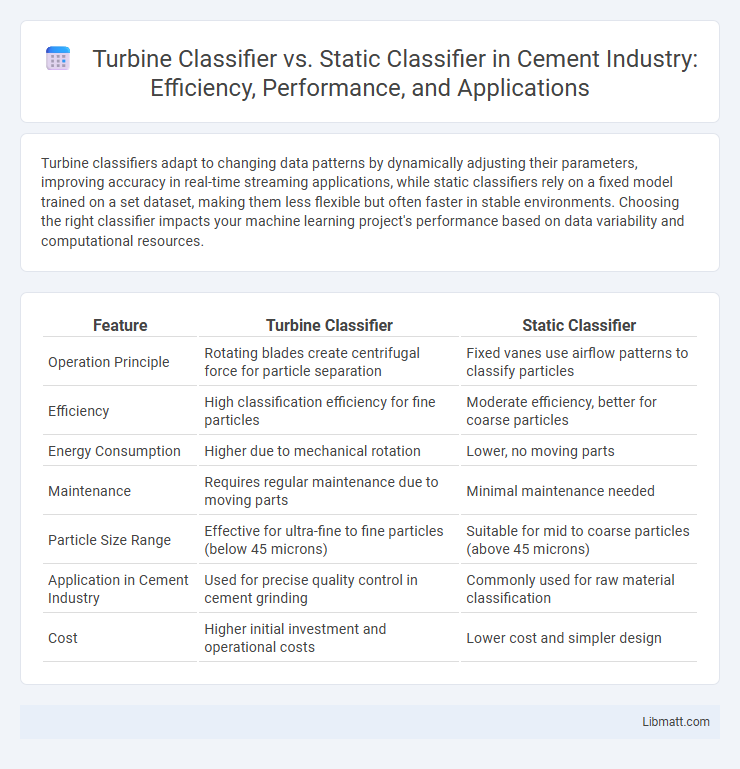

| Feature | Turbine Classifier | Static Classifier |

|---|---|---|

| Operation Principle | Rotating blades create centrifugal force for particle separation | Fixed vanes use airflow patterns to classify particles |

| Efficiency | High classification efficiency for fine particles | Moderate efficiency, better for coarse particles |

| Energy Consumption | Higher due to mechanical rotation | Lower, no moving parts |

| Maintenance | Requires regular maintenance due to moving parts | Minimal maintenance needed |

| Particle Size Range | Effective for ultra-fine to fine particles (below 45 microns) | Suitable for mid to coarse particles (above 45 microns) |

| Application in Cement Industry | Used for precise quality control in cement grinding | Commonly used for raw material classification |

| Cost | Higher initial investment and operational costs | Lower cost and simpler design |

Introduction to Turbine and Static Classifiers

Turbine classifiers utilize rotating blades or turbines to separate particles based on size and density, offering dynamic and precise classification in industrial processes. Static classifiers rely on fixed vanes or baffles to direct airflow and segregate materials without moving parts, ensuring simplicity and durability in operation. Understanding the fundamental differences between your turbine and static classifier options helps optimize material sorting efficiency.

Key Differences Between Turbine and Static Classifiers

Turbine classifiers use a dynamic airflow generated by rapidly spinning rotors to separate particles based on size and density, while static classifiers rely on fixed physical barriers or gravity-based separation without moving parts. The turbine classifier offers enhanced precision in particle separation due to adjustable rotor speed, making it suitable for finer materials, whereas static classifiers are more cost-effective and have lower maintenance requirements. Efficiency in handling higher feed rates and achieving narrower particle size distributions distinguishes turbine classifiers from their static counterparts.

Working Principle of Turbine Classifiers

Turbine classifiers operate using a rotating impeller that creates a centrifugal airflow to separate particles based on size and density, enabling precise classification of materials. Unlike static classifiers, turbine classifiers adjust the rotor speed to control cut point and particle size distribution dynamically. Your processing efficiency improves as turbine classifiers offer enhanced separation accuracy and adaptability to varying feed conditions.

How Static Classifiers Operate

Static classifiers operate by analyzing fixed features extracted from input data without adapting to changes in real-time data distribution. They rely on predefined rules or trained models using historical datasets, which limits their flexibility when encountering novel or evolving patterns. These classifiers typically use feature vectors and decision boundaries established during the training phase to categorize incoming instances consistently.

Efficiency Comparison: Turbine vs Static Classifiers

Turbine classifiers typically offer higher efficiency in particle size separation due to their dynamic rotor-stator design, which enhances material flow and reduces recirculation compared to static classifiers. Static classifiers rely on fixed geometry and aerodynamic forces, often resulting in lower throughput and increased energy consumption for equivalent separation performance. The adjustable operational parameters of turbine classifiers enable optimized classification efficiency, making them more suitable for high-capacity and precision sorting applications.

Particle Size Control and Precision

Turbine classifiers offer superior particle size control by utilizing adjustable rotor speeds and air flow to precisely separate fine particles, achieving narrow size distribution with high consistency. Static classifiers rely on fixed geometric design and airflow paths, providing less flexibility and coarser control over particle size distribution compared to turbine models. The dynamic adjustment capability in turbine classifiers enables enhanced precision in tailoring particle size for various industrial applications, outperforming static classifiers in selective separation efficiency.

Energy Consumption and Operational Costs

Turbine classifiers typically consume less energy compared to static classifiers due to their dynamic air flow mechanisms that optimize particle separation efficiency. Operational costs for turbine classifiers are generally lower as the reduced energy demand translates into decreased power expenses and less frequent maintenance caused by mechanical wear. Static classifiers, while simpler in design, often incur higher energy consumption and elevated operational costs due to continuous airflow requirements and more frequent component replacements.

Applications in Various Industries

Turbine classifiers excel in industries requiring precise particle size control, such as mining, cement, and pharmaceuticals, by utilizing centrifugal force to enhance material separation efficiency. Static classifiers, commonly used in power plants and mineral processing, rely on fixed blades to separate particles based on aerodynamic properties, offering simplicity and cost-effectiveness for large-scale operations. Your choice between turbine and static classifiers should consider factors like desired classification accuracy, throughput, and maintenance requirements to optimize performance in specific industrial applications.

Maintenance and Durability Considerations

Turbine classifiers require regular maintenance due to their rotating components, which are subject to wear and require periodic inspection and lubrication. Static classifiers have fewer moving parts, resulting in lower maintenance needs and longer durability under continuous operation. Your choice will depend on the balance between maintenance resources and the expected lifespan for consistent classification performance.

Choosing the Right Classifier for Your Needs

Selecting the right classifier depends on data complexity and processing requirements; Turbine Classifiers excel in dynamic environments with fluctuating input, offering adaptive, real-time sorting capabilities. Static Classifiers provide stable performance in consistent, predictable settings with less computational overhead, ideal for fixed parameter sorting tasks. Evaluating factors such as variability, throughput demands, and system flexibility ensures optimal alignment between classifier choice and operational goals.

Turbine Classifier vs Static Classifier Infographic

libmatt.com

libmatt.com