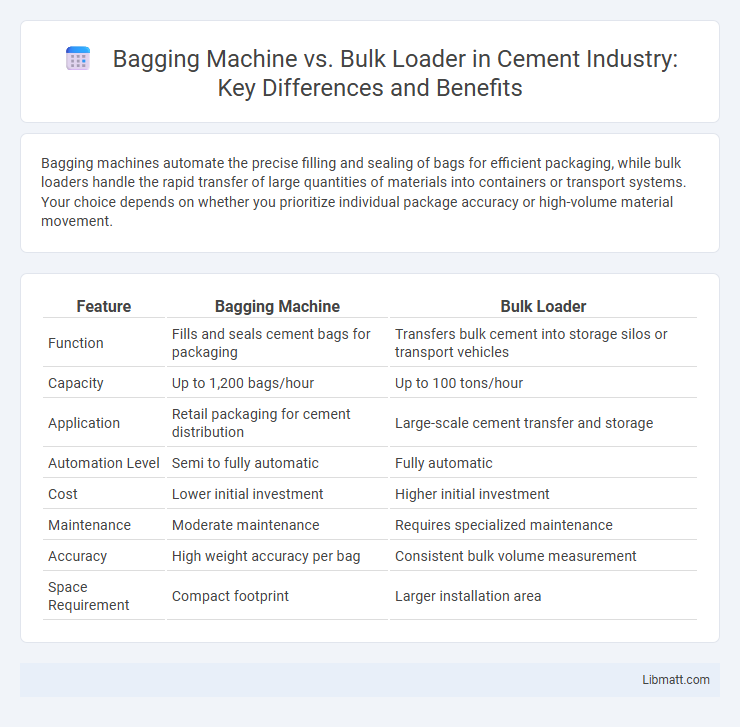

Bagging machines automate the precise filling and sealing of bags for efficient packaging, while bulk loaders handle the rapid transfer of large quantities of materials into containers or transport systems. Your choice depends on whether you prioritize individual package accuracy or high-volume material movement.

Table of Comparison

| Feature | Bagging Machine | Bulk Loader |

|---|---|---|

| Function | Fills and seals cement bags for packaging | Transfers bulk cement into storage silos or transport vehicles |

| Capacity | Up to 1,200 bags/hour | Up to 100 tons/hour |

| Application | Retail packaging for cement distribution | Large-scale cement transfer and storage |

| Automation Level | Semi to fully automatic | Fully automatic |

| Cost | Lower initial investment | Higher initial investment |

| Maintenance | Moderate maintenance | Requires specialized maintenance |

| Accuracy | High weight accuracy per bag | Consistent bulk volume measurement |

| Space Requirement | Compact footprint | Larger installation area |

Introduction to Bagging Machines and Bulk Loaders

Bagging machines are automated devices designed to efficiently fill and seal bags with bulk materials such as grains, powders, or pellets, ensuring consistent weight and packaging speed. Bulk loaders, on the other hand, handle larger volumes by transferring bulk materials into trucks, railcars, or storage silos, optimizing loading time and reducing manual labor. Understanding the differences between bagging machines and bulk loaders helps you choose the right equipment for your material handling needs based on capacity and application.

Key Features of Bagging Machines

Bagging machines automate the process of filling and sealing bags with consistent weight and speed, enhancing packaging efficiency for various products such as grains, powders, and granules. Key features include precise dosing systems, versatile bag types compatibility, and integrated sealing mechanisms that ensure product protection and reduce waste. Your packaging line benefits from reduced labor costs and improved accuracy by using bagging machines over bulk loaders designed primarily for large volume transfer without detailed packaging control.

Core Advantages of Bulk Loaders

Bulk loaders offer significant time savings by efficiently importing large volumes of data directly into databases, bypassing conventional insert operations. They optimize resource utilization by minimizing logging and locking, which enhances database performance and reduces downtime during large-scale data migrations. You benefit from streamlined processing, improved speed, and scalability when handling bulk data transfer tasks compared to traditional bagging machine methods.

Applications in Various Industries

Bagging machines are widely used in agriculture, food processing, and pharmaceuticals for efficiently packaging granular and powdered products, ensuring consistent weight and sealing quality. Bulk loaders are essential in construction, mining, and logistics industries where large volumes of materials like sand, gravel, and minerals require fast and automated loading into transport vehicles or storage systems. Your choice between bagging machines and bulk loaders depends on the scale and nature of material handling needs in your specific industry.

Operational Efficiency Comparison

Bagging machines offer precise portion control and consistent sealing speed, enhancing operational efficiency in packaging lines by reducing product spillage and minimizing waste. Bulk loaders excel in handling large volumes quickly, optimizing throughput for high-capacity production environments but may require more cleanup time and manual intervention. Your choice between bagging machines and bulk loaders depends on balancing speed, accuracy, and labor costs to maximize overall operational efficiency.

Cost Analysis: Bagging Machine vs Bulk Loader

The cost analysis between a bagging machine and a bulk loader reveals significant differences in initial investment and operational expenses. Bagging machines typically involve higher upfront costs due to advanced automation and packaging precision, while bulk loaders offer lower capital expenditure but increased labor and maintenance costs. Operational efficiency, material handling volume, and long-term savings must be evaluated to determine the most cost-effective solution for specific industrial applications.

Maintenance Requirements and Lifespan

Bagging machines typically require regular maintenance including lubrication, calibration, and part replacements to ensure optimal performance and extend their lifespan, which generally ranges from 7 to 10 years depending on usage intensity. Bulk loaders demand less frequent maintenance due to fewer moving parts but require periodic inspection of feeding mechanisms and sensors to prevent downtime, often achieving lifespans exceeding 10 years with proper care. Both equipment types benefit from scheduled maintenance protocols to maximize operational efficiency and avoid costly breakdowns.

Environmental Impact and Sustainability

Bagging machines typically use plastic or paper materials that may contribute to waste, while bulk loaders minimize packaging by transporting goods in larger quantities, reducing overall material consumption. Bulk loading systems tend to have a lower carbon footprint due to decreased packaging needs and streamlined logistics, supporting sustainable supply chain practices. Your choice between these methods can significantly influence environmental outcomes, with bulk loaders offering a more eco-friendly alternative aligned with sustainability goals.

Choosing the Right Equipment for Your Business

Choosing between a Bagging Machine and a Bulk Loader depends on your business scale and product type. Bagging Machines offer precision, ideal for small to medium batches requiring consistent packaging, while Bulk Loaders handle large volumes efficiently with less manual intervention. Evaluating your production speed, product characteristics, and budget ensures you select equipment that optimizes workflow and reduces operational costs.

Future Trends in Packaging and Bulk Handling Technology

Future trends in packaging and bulk handling technology emphasize automation, enhanced precision, and sustainability. Bagging machines are evolving with smart sensors and AI integration to optimize fill accuracy and reduce waste, while bulk loaders increasingly incorporate robotics for faster, safer material transfer. Your operations can benefit from these advancements by improving efficiency, minimizing downtime, and adapting to environmentally friendly packaging standards.

Bagging Machine vs Bulk Loader Infographic

libmatt.com

libmatt.com