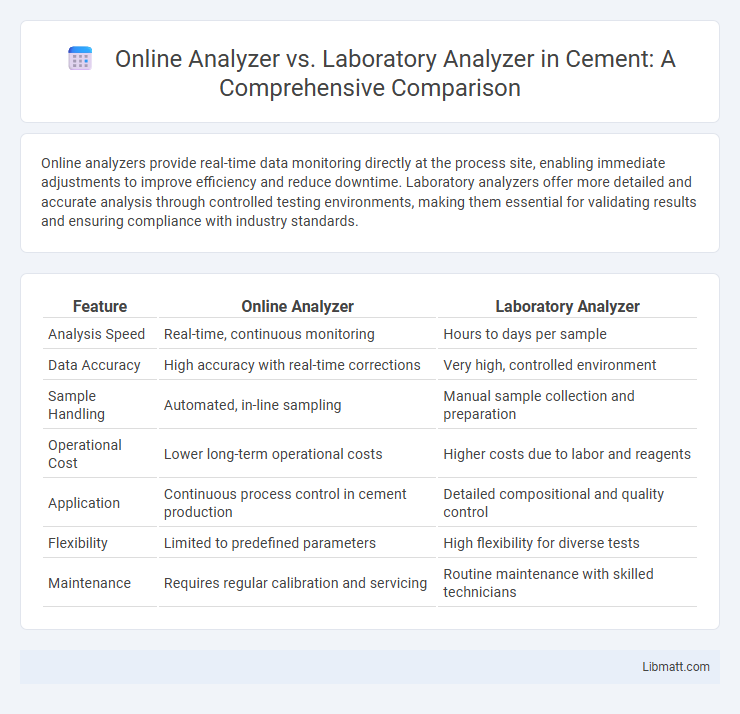

Online analyzers provide real-time data monitoring directly at the process site, enabling immediate adjustments to improve efficiency and reduce downtime. Laboratory analyzers offer more detailed and accurate analysis through controlled testing environments, making them essential for validating results and ensuring compliance with industry standards.

Table of Comparison

| Feature | Online Analyzer | Laboratory Analyzer |

|---|---|---|

| Analysis Speed | Real-time, continuous monitoring | Hours to days per sample |

| Data Accuracy | High accuracy with real-time corrections | Very high, controlled environment |

| Sample Handling | Automated, in-line sampling | Manual sample collection and preparation |

| Operational Cost | Lower long-term operational costs | Higher costs due to labor and reagents |

| Application | Continuous process control in cement production | Detailed compositional and quality control |

| Flexibility | Limited to predefined parameters | High flexibility for diverse tests |

| Maintenance | Requires regular calibration and servicing | Routine maintenance with skilled technicians |

Introduction to Analyzers: Online vs Laboratory

Online analyzers provide real-time monitoring and analysis of samples directly within industrial processes, enabling immediate adjustments to optimize performance and ensure compliance. Laboratory analyzers, by contrast, require sample extraction and controlled testing environments, offering precise and comprehensive results but with inherent time delays. The choice between online and laboratory analyzers depends on the need for speed, accuracy, and process integration in industries such as chemical manufacturing, water treatment, and pharmaceuticals.

Core Principles of Online and Laboratory Analysis

Online analyzers operate based on real-time monitoring technologies such as spectroscopy, electrochemical sensors, or chromatography, allowing continuous data collection and immediate process adjustments. Laboratory analyzers rely on standardized, validated methods with controlled environments to ensure high accuracy and precision, often involving manual sample preparation and batch analysis. Your choice depends on whether you prioritize instant feedback for process control or detailed, confirmatory results for quality assurance.

Key Differences Between Online and Laboratory Analyzers

Online analyzers provide real-time, continuous monitoring of chemical compositions directly within industrial processes, enabling immediate adjustments and enhanced process control. Laboratory analyzers involve periodic sampling and offline testing, offering high accuracy and detailed analysis but with delayed results that may impact timely decision-making. The primary differences lie in response time, integration level, and the balance between speed and analytical precision for process optimization.

Accuracy and Reliability: Online vs Laboratory

Laboratory analyzers generally provide higher accuracy and reliability due to controlled environments and rigorous calibration standards, which ensure precise measurements critical for detailed analyses. Online analyzers offer real-time data with acceptable accuracy for process monitoring but may be influenced by environmental factors and require frequent maintenance to maintain reliability. Your choice depends on whether immediate results or the highest precision is more critical for your application.

Real-Time Monitoring Capabilities

Online analyzers provide continuous real-time monitoring capabilities, enabling instant detection of process variations and immediate corrective actions, which significantly reduces downtime and enhances operational efficiency. Laboratory analyzers, while highly accurate and detailed, typically involve sample collection and processing times that delay feedback and limit their ability to support real-time decision-making. The integration of online analyzers with process control systems offers critical advantages in maintaining consistent product quality and optimizing production workflows.

Application Areas and Industry Use Cases

Online analyzers are extensively used in continuous process monitoring across industries such as petrochemical, wastewater treatment, and food and beverage production, providing real-time data for immediate decision-making and process optimization. Laboratory analyzers are preferred for highly precise and detailed analysis in pharmaceuticals, environmental testing, and quality control labs, enabling comprehensive sample characterization under controlled conditions. Both analyzer types complement each other in sectors like chemical manufacturing and mining, where online systems ensure operational efficiency while laboratory analyzers validate results and support regulatory compliance.

Cost Implications and Operational Efficiency

Online analyzers typically reduce ongoing costs by minimizing the need for sample transportation and labor-intensive manual testing, leading to significant operational efficiency gains in continuous monitoring processes. Laboratory analyzers, while involving higher expenses for sample handling and delayed results, provide more comprehensive and precise analysis necessary for complex quality control scenarios. Choosing the right analyzer impacts your budget planning and operational workflow optimization, balancing upfront investment with long-term cost savings and accuracy needs.

Maintenance and Calibration Needs

Online analyzers require frequent maintenance and automatic calibration to ensure continuous real-time data accuracy, reducing downtime in industrial processes. Laboratory analyzers depend on periodic manual calibration and maintenance, which can lead to delays and interrupted sample analysis. Your choice between the two should consider the balance between ongoing maintenance demands and the need for uninterrupted, precise measurement results.

Data Integration and Reporting Features

Online analyzers provide real-time data integration with seamless connectivity to existing digital systems, enabling instantaneous monitoring and reporting of critical parameters. Laboratory analyzers typically require manual data entry or batch uploads, which can delay analysis and limit timely decision-making. You benefit from enhanced efficiency and accuracy in operational reporting when utilizing online analyzers for continuous, automated data capture and dynamic visualization.

Choosing the Right Analyzer for Your Process

Choosing the right analyzer depends on the specific requirements of your process, including accuracy, response time, and environmental conditions. Online analyzers provide continuous real-time monitoring, ideal for immediate process control and automation, while laboratory analyzers offer high-precision analysis best suited for detailed quality control and validation. Evaluating factors such as sample type, maintenance needs, and integration capabilities ensures optimal analyzer selection for enhanced process efficiency and reliability.

Online Analyzer vs Laboratory Analyzer Infographic

libmatt.com

libmatt.com