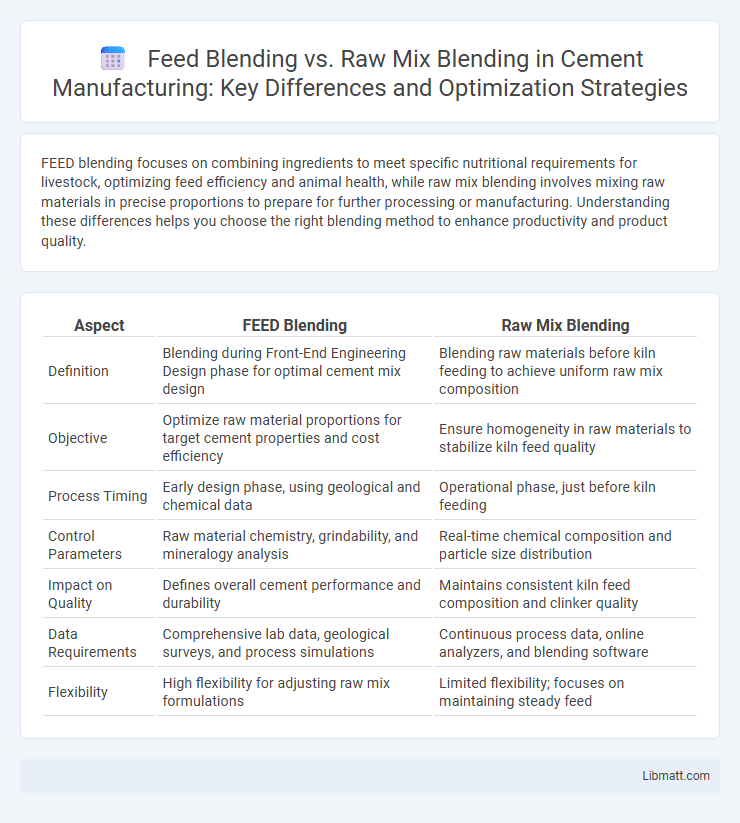

FEED blending focuses on combining ingredients to meet specific nutritional requirements for livestock, optimizing feed efficiency and animal health, while raw mix blending involves mixing raw materials in precise proportions to prepare for further processing or manufacturing. Understanding these differences helps you choose the right blending method to enhance productivity and product quality.

Table of Comparison

| Aspect | FEED Blending | Raw Mix Blending |

|---|---|---|

| Definition | Blending during Front-End Engineering Design phase for optimal cement mix design | Blending raw materials before kiln feeding to achieve uniform raw mix composition |

| Objective | Optimize raw material proportions for target cement properties and cost efficiency | Ensure homogeneity in raw materials to stabilize kiln feed quality |

| Process Timing | Early design phase, using geological and chemical data | Operational phase, just before kiln feeding |

| Control Parameters | Raw material chemistry, grindability, and mineralogy analysis | Real-time chemical composition and particle size distribution |

| Impact on Quality | Defines overall cement performance and durability | Maintains consistent kiln feed composition and clinker quality |

| Data Requirements | Comprehensive lab data, geological surveys, and process simulations | Continuous process data, online analyzers, and blending software |

| Flexibility | High flexibility for adjusting raw mix formulations | Limited flexibility; focuses on maintaining steady feed |

Introduction to FEED Blending and Raw Mix Blending

FEED Blending involves combining pre-analyzed feed materials to achieve consistent composition before processing, optimizing ingredient proportions and chemical properties. Raw Mix Blending, on the other hand, focuses on mixing raw materials directly extracted from sources without prior analysis, often requiring adjustments during production to meet specifications. Your choice between FEED Blending and Raw Mix Blending impacts process efficiency, product uniformity, and cost management in industries like cement and chemical manufacturing.

Definitions: What is FEED Blending?

FEED Blending refers to the process of mixing various feedstock materials in precise proportions before they enter the production system to ensure consistent quality and performance. It involves combining raw materials based on detailed Front-End Engineering Design (FEED) specifications to optimize chemical composition and physical properties. This blending approach contrasts with Raw Mix Blending, which primarily focuses on homogenizing raw materials before initial processing.

Definitions: What is Raw Mix Blending?

Raw Mix Blending involves the precise combination of raw materials such as limestone, clay, and sand to create a homogeneous mixture before clinker production in cement manufacturing. This process ensures consistent chemical composition and optimal kiln performance by balancing components like silica, alumina, and iron oxide. Controlling raw mix proportions is essential for reducing energy consumption and achieving desired clinker quality.

Key Differences Between FEED Blending and Raw Mix Blending

FEED blending involves the precise combination of raw materials before grinding to achieve consistent feed composition, while raw mix blending focuses on homogenizing ground materials to ensure uniform chemical properties. You benefit from FEED blending through improved kiln performance and fuel efficiency, whereas raw mix blending optimizes the final product quality by balancing components before firing. Key differences include the stage of blending and the granularity of material control, impacting overall cement production efficiency.

Advantages of FEED Blending

FEED Blending offers precise control over raw material proportions, resulting in consistent product quality and reduced variability in cement production. By integrating advanced sensors and automated systems, FEED Blending minimizes manual errors and enhances process efficiency, ultimately lowering operational costs. Your plant benefits from increased flexibility in adjusting mix formulations to meet specific performance criteria and environmental standards.

Advantages of Raw Mix Blending

Raw Mix Blending offers superior consistency in cement production by ensuring uniform chemical composition, which enhances clinker quality and energy efficiency. This method reduces variability in raw materials, leading to optimized kiln performance and lower fuel consumption. Your plant benefits from improved process control, resulting in cost savings and higher final product reliability.

Challenges in FEED Blending Processes

FEED blending faces challenges such as achieving precise ingredient ratios to maintain nutrient balance and prevent feed quality variations. Variability in raw material moisture content and particle size complicate uniform mixing, impacting animal performance and feed efficiency. Your ability to monitor and control these variables directly influences the consistency and effectiveness of the final feed product.

Challenges in Raw Mix Blending Operations

Raw mix blending operations face significant challenges due to the variability in raw material properties such as moisture content, particle size, and chemical composition, which can lead to inconsistent product quality. Managing precise chemical homogenization while compensating for fluctuating feed material characteristics demands advanced process controls and real-time monitoring systems. Your production efficiency and cement quality heavily depend on overcoming these raw mix blending difficulties to ensure stable kiln operation and uniform clinker composition.

Applications and Industry Use Cases

FEED Blending optimizes raw materials for energy production, particularly in cement and power plants, ensuring consistent fuel quality and reducing emissions. Raw Mix Blending is essential in the cement manufacturing industry for homogenizing raw materials like limestone, clay, and iron ore, which enhances kiln efficiency and product quality. Your choice between FEED Blending and Raw Mix Blending depends on the industrial application, with FEED suited for fuel preparation and Raw Mix blending critical for raw material processing.

Conclusion: Choosing the Right Blending Method

Selecting the appropriate blending method depends on your production goals and resource availability. FEED blending offers better control over feedstock quality and consistency, while Raw Mix blending provides cost efficiency by blending raw materials before processing. Your choice should balance operational efficiency with desired product specifications to optimize overall performance.

FEED Blending vs Raw Mix Blending Infographic

libmatt.com

libmatt.com