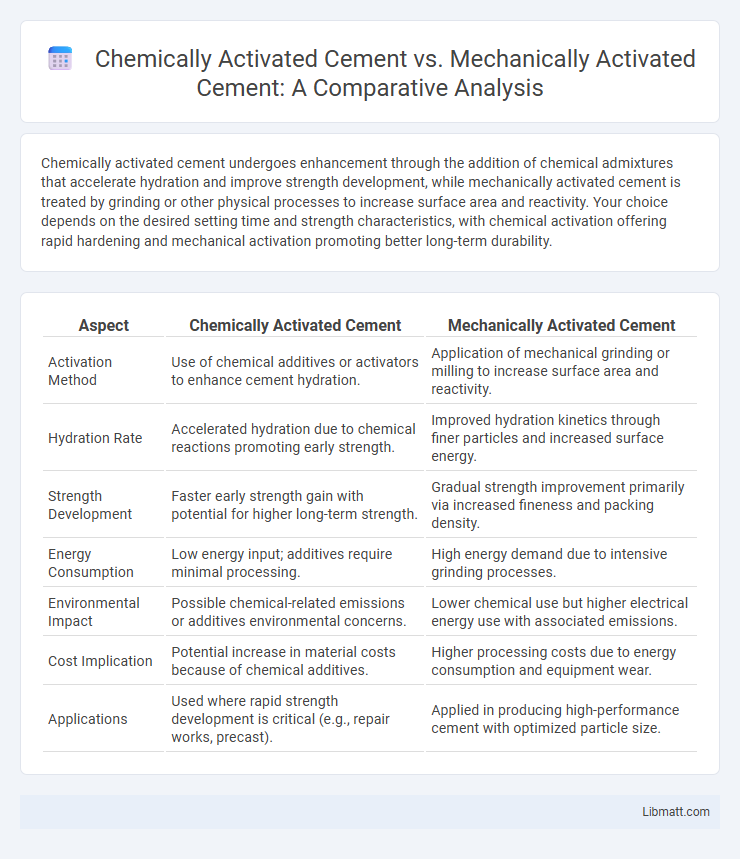

Chemically activated cement undergoes enhancement through the addition of chemical admixtures that accelerate hydration and improve strength development, while mechanically activated cement is treated by grinding or other physical processes to increase surface area and reactivity. Your choice depends on the desired setting time and strength characteristics, with chemical activation offering rapid hardening and mechanical activation promoting better long-term durability.

Table of Comparison

| Aspect | Chemically Activated Cement | Mechanically Activated Cement |

|---|---|---|

| Activation Method | Use of chemical additives or activators to enhance cement hydration. | Application of mechanical grinding or milling to increase surface area and reactivity. |

| Hydration Rate | Accelerated hydration due to chemical reactions promoting early strength. | Improved hydration kinetics through finer particles and increased surface energy. |

| Strength Development | Faster early strength gain with potential for higher long-term strength. | Gradual strength improvement primarily via increased fineness and packing density. |

| Energy Consumption | Low energy input; additives require minimal processing. | High energy demand due to intensive grinding processes. |

| Environmental Impact | Possible chemical-related emissions or additives environmental concerns. | Lower chemical use but higher electrical energy use with associated emissions. |

| Cost Implication | Potential increase in material costs because of chemical additives. | Higher processing costs due to energy consumption and equipment wear. |

| Applications | Used where rapid strength development is critical (e.g., repair works, precast). | Applied in producing high-performance cement with optimized particle size. |

Introduction to Chemically and Mechanically Activated Cement

Chemically activated cement involves the addition of chemical admixtures to enhance the hydration process, improving strength and setting time. Mechanically activated cement is produced through grinding or milling, which increases the surface area and reactivity of the cement particles. Both activation methods significantly influence the performance characteristics and durability of cement in construction applications.

Defining Chemically Activated Cement

Chemically activated cement involves the addition of chemical activators such as alkalis, sulfates, or chlorides to enhance the hydration process and improve early strength development. This method contrasts with mechanically activated cement, which relies on grinding or milling to increase surface area and reactivity. Understanding chemically activated cement helps you optimize construction materials for faster curing and improved durability in specialized applications.

Understanding Mechanically Activated Cement

Mechanically activated cement is produced by grinding raw cement materials to increase surface area, enhancing reactivity and strength development. This activation method improves particle size distribution and promotes chemical reactions during hydration, resulting in faster setting times and higher early strength compared to chemically activated cement. Optimizing grinding parameters is crucial to maximize the mechanical activation benefits and achieve superior cement performance.

Key Differences in Activation Processes

Chemically activated cement involves the addition of chemical activators like alkalis or sulfates to initiate the hydration process, enhancing early strength development and reducing setting time. Mechanically activated cement is produced by grinding raw materials to increase surface area and reactivity, improving cement efficiency without altering its chemical composition. Understanding these key differences in activation processes helps you choose the right cement type for specific construction needs.

Chemical Activation: Advantages and Limitations

Chemical activation of cement enhances hydration kinetics, improving early strength development and durability through the addition of activators like alkalis or sulfates that trigger rapid and complete cement reactions. This activation method reduces curing time and energy consumption, increasing efficiency in construction projects with demanding schedules. However, chemical activators may impact the long-term stability and environmental sustainability of your concrete, as excessive use can lead to efflorescence or undesirable changes in microstructure.

Mechanical Activation: Benefits and Challenges

Mechanical activation improves cement reactivity by increasing surface area and inducing structural changes, resulting in enhanced strength and faster hydration rates. However, challenges include higher energy consumption during grinding and potential agglomeration that can reduce effectiveness. Understanding these benefits and limitations helps optimize your cement production process for superior performance.

Comparative Performance and Durability

Chemically activated cement demonstrates enhanced early strength development and improved long-term durability due to accelerated hydration reactions and optimized microstructure refinement. Mechanically activated cement, achieved through high-energy grinding processes, exhibits increased surface area and reactivity, resulting in better particle dispersion and reduced porosity, which contribute to superior mechanical performance. Comparative studies reveal that chemically activated cements often outperform mechanically activated variants in sulfate resistance and chloride ion penetration, while mechanical activation offers advantages in improving workability and energy efficiency during production.

Environmental Impact and Sustainability

Chemically activated cement reduces CO2 emissions by utilizing industrial by-products like fly ash and slag, enhancing sustainability through lower clinker content and waste valorization. Mechanically activated cement improves reactivity and strength by grinding raw materials to finer particles, which can increase energy consumption but also improve performance and durability, potentially extending service life and reducing overall environmental impact. Your choice between these cements influences your project's carbon footprint and long-term ecological sustainability.

Applications in the Construction Industry

Chemically activated cement is widely used in rapid-setting concrete applications such as precast elements, repair works, and underwater constructions due to its enhanced early strength and durability. Mechanically activated cement, produced through grinding or milling processes, improves the reactivity and fineness of cement particles, making it ideal for high-performance concrete and sustainable construction projects by reducing clinker content. Your choice between these cements depends on the specific performance requirements and environmental considerations of your construction project.

Future Trends in Cement Activation Technologies

Future trends in cement activation technologies emphasize the integration of nanotechnology and advanced chemical admixtures to enhance chemically activated cement performance, accelerating hydration and improving durability. Mechanically activated cement advancements focus on optimizing particle size distribution through high-energy milling and ultrafine grinding, leading to higher reactivity and reduced carbon footprint. Hybrid approaches combining chemical and mechanical activation are emerging, aiming to maximize cement efficiency while aligning with sustainable construction demands.

Chemically Activated Cement vs Mechanically Activated Cement Infographic

libmatt.com

libmatt.com