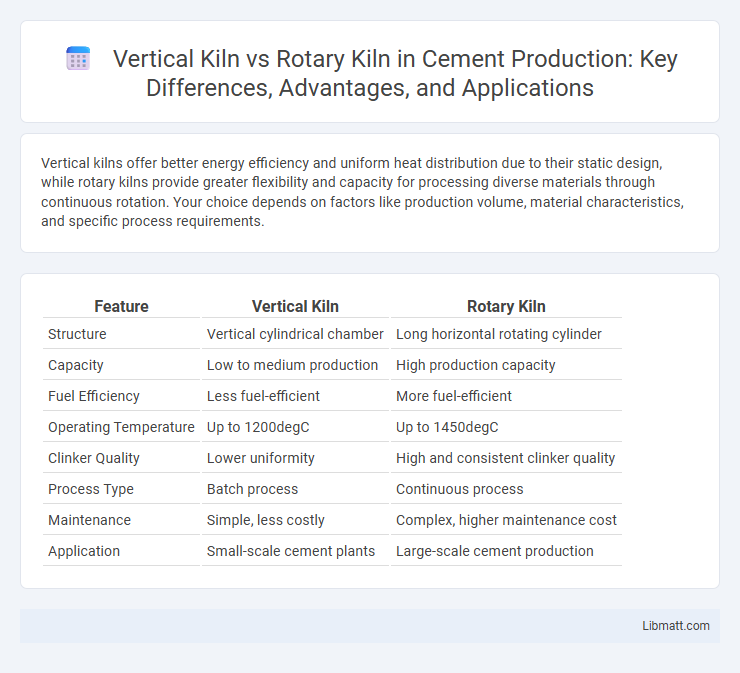

Vertical kilns offer better energy efficiency and uniform heat distribution due to their static design, while rotary kilns provide greater flexibility and capacity for processing diverse materials through continuous rotation. Your choice depends on factors like production volume, material characteristics, and specific process requirements.

Table of Comparison

| Feature | Vertical Kiln | Rotary Kiln |

|---|---|---|

| Structure | Vertical cylindrical chamber | Long horizontal rotating cylinder |

| Capacity | Low to medium production | High production capacity |

| Fuel Efficiency | Less fuel-efficient | More fuel-efficient |

| Operating Temperature | Up to 1200degC | Up to 1450degC |

| Clinker Quality | Lower uniformity | High and consistent clinker quality |

| Process Type | Batch process | Continuous process |

| Maintenance | Simple, less costly | Complex, higher maintenance cost |

| Application | Small-scale cement plants | Large-scale cement production |

Introduction to Vertical Kilns and Rotary Kilns

Vertical kilns feature a tall, cylindrical structure where materials move downward by gravity, commonly used for processes like lime calcination due to their energy efficiency and lower operational costs. Rotary kilns consist of a rotating cylindrical shell, providing continuous material mixing and high-temperature processing ideal for cement production and metallurgical applications. Understanding the differences between your vertical kiln and rotary kiln options can optimize thermal processing performance based on capacity, fuel consumption, and product uniformity requirements.

Key Differences in Design and Structure

Vertical kilns feature a stationary cylindrical structure with raw materials descending through evenly heated zones, promoting energy-efficient combustion and uniform heat distribution. Rotary kilns have a rotating cylindrical shell slightly inclined to facilitate gradual material movement, allowing precise control over temperature profiles and extended processing times. The vertical kiln's compact design contrasts with the rotary kiln's larger, lengthwise configuration, influencing installation space and operational scalability.

Operational Principles: How Each Kiln Works

Vertical kilns operate by feeding raw material from the top, allowing it to descend through multiple combustion zones, where heat is applied primarily by countercurrent gas flow, enabling efficient heat exchange and gradual material calcination. Rotary kilns consist of a rotating cylindrical shell inclined slightly to facilitate continuous material movement from the feed end to the discharge end, where direct contact with the flame and combustion gases ensures uniform heating and chemical reactions. Each kiln's operational design influences temperature distribution, retention time, and fuel efficiency, with vertical kilns favoring batch-like processing and rotary kilns supporting continuous, intensive thermal treatment.

Energy Efficiency Comparison

Vertical kilns generally exhibit higher energy efficiency than rotary kilns due to their simpler design and counter-current heat exchange, which allows better heat retention and reduced fuel consumption. Rotary kilns, while versatile and suitable for various materials, often consume more energy because of continuous rotation and larger heat losses. Optimizing kiln selection based on your production requirements can significantly impact overall energy consumption and operational costs.

Raw Material Compatibility

Vertical kilns excel in processing raw materials with lower plasticity and limited moisture content, making them ideal for materials like limestone and clay with consistent particle sizes. Rotary kilns offer greater versatility, accommodating a wide range of raw materials including those with higher moisture, variable particle sizes, and higher plasticity due to their continuous rotating mechanism and uniform heat distribution. Industries prefer rotary kilns when raw material variability and moisture content demand more flexible thermal processing capabilities.

Product Quality and Consistency

Vertical kilns provide superior product quality and consistency by offering precise temperature control and uniform heat distribution, minimizing defects and ensuring even material processing. Rotary kilns, while versatile and efficient for large-scale operations, may experience temperature fluctuations and uneven heat exposure that can affect product uniformity. Your choice between these kiln types will significantly impact the consistency and quality of the final output based on the production scale and material requirements.

Cost of Installation and Maintenance

Vertical kilns generally have lower installation costs due to simpler design and smaller footprint compared to rotary kilns, which require more complex infrastructure and foundations. Maintenance expenses for vertical kilns tend to be higher because their solid fuel combustion and heat transfer mechanisms lead to quicker wear and frequent component replacements. Rotary kilns, although initially more expensive, benefit from streamlined maintenance processes and longer-lasting refractory linings, resulting in lower long-term maintenance costs.

Environmental Impact and Emissions

Vertical kilns generally produce lower emissions due to their efficient fuel combustion and reduced heat loss compared to rotary kilns. Rotary kilns often emit higher levels of greenhouse gases and particulate matter because of their continuous rotation and longer retention times, resulting in increased fuel consumption. Understanding these environmental impacts can help you choose a kiln that aligns with your sustainability goals and regulatory compliance needs.

Industrial Applications and Suitability

Vertical kilns excel in industries requiring continuous production of cement and lime, offering energy efficiency and lower operating costs, making them suitable for smaller-scale operations. Rotary kilns provide versatility in processing a wide range of materials, including cement, refractories, and waste, with superior temperature control and uniform heating, ideal for large-scale industrial applications. Your choice depends on the specific production volume, material type, and desired quality in your manufacturing process.

Choosing the Right Kiln: Factors to Consider

Choosing the right kiln depends on factors like processing capacity, material type, and energy efficiency requirements. Vertical kilns are ideal for smaller, continuous batch production with lower energy consumption, while rotary kilns accommodate larger volumes and mixed feed materials with better temperature control. Your decision should consider operational costs, maintenance complexity, and product quality to optimize performance in cement or metallurgical industries.

Vertical kiln vs Rotary kiln Infographic

libmatt.com

libmatt.com