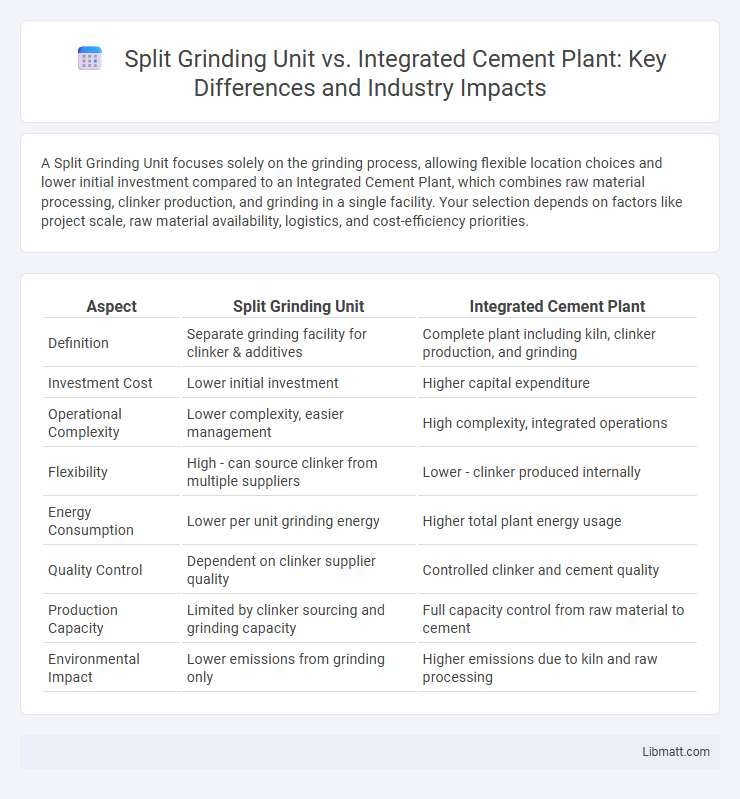

A Split Grinding Unit focuses solely on the grinding process, allowing flexible location choices and lower initial investment compared to an Integrated Cement Plant, which combines raw material processing, clinker production, and grinding in a single facility. Your selection depends on factors like project scale, raw material availability, logistics, and cost-efficiency priorities.

Table of Comparison

| Aspect | Split Grinding Unit | Integrated Cement Plant |

|---|---|---|

| Definition | Separate grinding facility for clinker & additives | Complete plant including kiln, clinker production, and grinding |

| Investment Cost | Lower initial investment | Higher capital expenditure |

| Operational Complexity | Lower complexity, easier management | High complexity, integrated operations |

| Flexibility | High - can source clinker from multiple suppliers | Lower - clinker produced internally |

| Energy Consumption | Lower per unit grinding energy | Higher total plant energy usage |

| Quality Control | Dependent on clinker supplier quality | Controlled clinker and cement quality |

| Production Capacity | Limited by clinker sourcing and grinding capacity | Full capacity control from raw material to cement |

| Environmental Impact | Lower emissions from grinding only | Higher emissions due to kiln and raw processing |

Introduction to Cement Manufacturing Processes

Split Grinding Units focus solely on grinding clinker imported from integrated plants, streamlining the production phases and reducing initial capital investment. Integrated Cement Plants combine raw material extraction, clinker production, and grinding within a single facility, offering greater control over quality and product customization. Your choice depends on factors like production scale, resource availability, and logistical efficiency in cement manufacturing processes.

Overview of Split Grinding Units

Split grinding units operate as specialized facilities dedicated solely to the milling and grinding of clinker into cement, enhancing flexibility in production and reducing transportation costs when located near key markets. These units often complement integrated cement plants by optimizing capacity utilization and allowing for easier scaling of operations based on demand. Your choice between a split grinding unit and an integrated cement plant depends on factors such as logistical efficiency, investment capacity, and market proximity.

What is an Integrated Cement Plant?

An Integrated Cement Plant combines all processes from raw material extraction to clinker production and cement grinding within one facility, ensuring efficient energy use and streamlined operations. Unlike the Split Grinding Unit, which only handles the final grinding phase, the integrated plant controls quality and production at every stage, reducing transportation costs and emissions. Your choice of an integrated plant supports comprehensive production management and higher operational consistency.

Key Differences Between Split Grinding Units and Integrated Plants

Split grinding units primarily focus on grinding clinker and other raw materials, operating independently from clinker production, while integrated cement plants handle both clinker production and grinding within the same facility. Integrated plants offer streamlined operations with reduced transportation costs and enhanced process control, whereas split units provide flexibility in sourcing clinker and can be located closer to end markets. Your choice depends on factors such as capital investment, logistical efficiency, and production scale requirements.

Infrastructure and Location Considerations

Split Grinding Units require less on-site infrastructure, making them ideal for locations with limited land availability or challenging terrain, while Integrated Cement Plants demand extensive facilities including clinker production, raw material storage, and power generation. Selecting the right location for a Split Grinding Unit often hinges on proximity to the market or raw material supply, whereas Integrated Plants depend heavily on access to abundant raw materials, transport links, and utilities. Your choice between these setups will impact capital investment, logistical efficiency, and operational scalability based on the surrounding infrastructure and site conditions.

Energy Efficiency and Environmental Impact

Split grinding units offer greater energy efficiency by allowing separate optimization of clinker production and grinding processes, reducing overall power consumption compared to integrated cement plants. Integrated plants, while benefiting from centralized operations, often face higher emissions due to continuous kiln use and less flexible energy management. Your choice between these setups will influence not only operational costs but also environmental impact, with split grinding units typically enabling lower carbon emissions and improved sustainability.

Cost Effectiveness and Capital Investment

Split grinding units require lower capital investment compared to integrated cement plants due to reduced infrastructure and scale. Operating costs tend to be higher in split units because of additional transportation and logistics expenses for clinker and raw materials. Integrated cement plants offer greater cost effectiveness through economies of scale, streamlined production processes, and reduced material handling costs.

Supply Chain and Logistics Advantages

Split Grinding Units offer flexible supply chain management by allowing cement production closer to end-user markets, reducing transportation costs and lead times. Integrated Cement Plants consolidate raw material processing and clinker production in one location, which streamlines logistics internally but may increase distribution expenses for finished cement over long distances. You benefit from Split Grinding Units when targeting diverse regional markets with optimized delivery schedules and lower inventory requirements.

Quality Control and Product Consistency

Split Grinding Units offer enhanced quality control by allowing independent monitoring and adjustment of grinding parameters, ensuring precise particle size distribution tailored for specific cement grades. Integrated Cement Plants maintain product consistency through synchronized operations from kiln to mill, benefiting from a unified process flow that reduces variability in raw material and clinker quality. For your project, choosing between these options depends on whether you prioritize customizable quality control in Split Grinding Units or the streamlined consistency achieved in Integrated Cement Plants.

Choosing the Right Option for Your Cement Business

Split grinding units offer flexibility by allowing cement producers to separate raw material processing from clinker production, optimizing logistics and operational costs across multiple locations. Integrated cement plants consolidate all production stages, enhancing efficiency and quality control but requiring substantial capital investment and space. Selecting the ideal solution depends on factors such as market demand, transportation infrastructure, investment capacity, and long-term scalability goals.

Split Grinding Unit vs Integrated Cement Plant Infographic

libmatt.com

libmatt.com