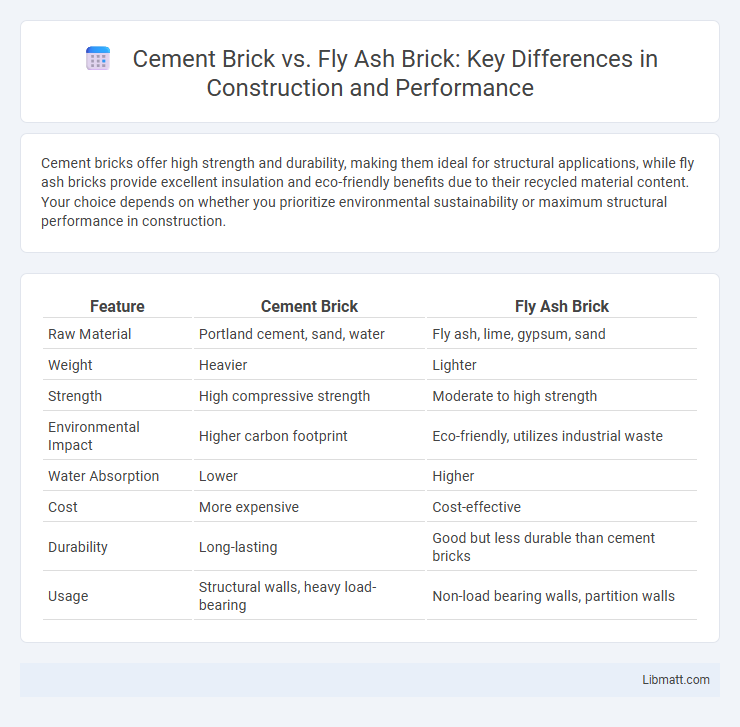

Cement bricks offer high strength and durability, making them ideal for structural applications, while fly ash bricks provide excellent insulation and eco-friendly benefits due to their recycled material content. Your choice depends on whether you prioritize environmental sustainability or maximum structural performance in construction.

Table of Comparison

| Feature | Cement Brick | Fly Ash Brick |

|---|---|---|

| Raw Material | Portland cement, sand, water | Fly ash, lime, gypsum, sand |

| Weight | Heavier | Lighter |

| Strength | High compressive strength | Moderate to high strength |

| Environmental Impact | Higher carbon footprint | Eco-friendly, utilizes industrial waste |

| Water Absorption | Lower | Higher |

| Cost | More expensive | Cost-effective |

| Durability | Long-lasting | Good but less durable than cement bricks |

| Usage | Structural walls, heavy load-bearing | Non-load bearing walls, partition walls |

Introduction to Cement Brick and Fly Ash Brick

Cement bricks are made from a mixture of cement, sand, and water, offering high compressive strength and durability for construction purposes. Fly ash bricks utilize fly ash, a byproduct of coal combustion, mixed with lime, gypsum, and sand, making them eco-friendly and lightweight. Choosing between the two affects your project's environmental impact, cost, and structural requirements.

Composition and Raw Materials

Cement bricks are primarily composed of cement, sand, and water, utilizing ordinary Portland cement as the key binding material. Fly ash bricks incorporate fly ash--a byproduct of coal combustion--alongside cement, lime, gypsum, and sand, offering an eco-friendly alternative with enhanced strength and durability. Selecting between cement bricks and fly ash bricks depends on the availability of raw materials and your preference for sustainable construction options.

Manufacturing Process Comparison

Cement bricks are manufactured by mixing cement, sand, and water, then pressing the mixture into molds and curing it to gain strength. Fly ash bricks are produced by combining fly ash, lime, gypsum, and water, followed by a curing process that utilizes steam or autoclaving to enhance durability. Your choice between these bricks impacts construction quality, as fly ash bricks often offer better insulation and environmental benefits due to their recycled material composition.

Strength and Durability Analysis

Cement bricks exhibit higher compressive strength, typically ranging from 3.5 to 7 N/mm2, compared to fly ash bricks, which generally have strength values between 2.8 to 5.5 N/mm2. Fly ash bricks offer superior durability due to their resistance to efflorescence, water absorption below 15%, and better thermal insulation properties, making them suitable for long-term structural applications. The incorporation of fly ash enhances the microstructure, resulting in reduced porosity and greater resistance to chemical attacks, contributing to their extended lifespan in construction projects.

Thermal and Acoustic Insulation Properties

Cement bricks offer moderate thermal insulation but tend to conduct heat more than fly ash bricks, which are known for their superior thermal insulation due to their lower density and porous structure. Fly ash bricks provide enhanced acoustic insulation, effectively reducing noise transmission in comparison to denser cement bricks. Choosing fly ash bricks can improve your building's energy efficiency and soundproofing, contributing to a more comfortable indoor environment.

Environmental Impact and Sustainability

Cement bricks generate higher carbon emissions due to the energy-intensive production of Portland cement, contributing significantly to environmental pollution. Fly ash bricks utilize industrial waste from coal-fired power plants, reducing landfill waste and conserving natural resources like clay and topsoil. Their sustainable manufacturing process results in lower carbon footprints and improved energy efficiency, making fly ash bricks a more eco-friendly choice for construction.

Cost-Effectiveness and Affordability

Fly ash bricks generally offer greater cost-effectiveness due to lower material costs and reduced energy consumption during production compared to cement bricks. Cement bricks tend to be more expensive because of higher cement content and manufacturing processes. You can achieve affordability by choosing fly ash bricks for large construction projects without compromising structural quality.

Applications and Suitability for Construction

Cement bricks offer high compressive strength and durability, making them ideal for load-bearing walls, foundations, and structural applications requiring long-term stability. Fly ash bricks provide excellent thermal insulation and are lightweight, suitable for non-load-bearing walls, partition walls, and eco-friendly construction projects aiming to reduce carbon footprint. Your choice depends on project requirements, where cement bricks suit heavy-duty construction while fly ash bricks optimize sustainability and energy efficiency.

Aesthetic Appeal and Design Versatility

Cement bricks offer a uniform texture and smooth surface, making them ideal for modern architectural designs that require a clean, consistent appearance. Fly ash bricks provide a unique aesthetic with slightly varied color tones and natural finish, lending themselves well to eco-friendly and rustic design schemes. Your choice depends on whether you prioritize sleek uniformity with cement bricks or sustainable, textured appeal with fly ash bricks.

Conclusion: Choosing the Right Brick

Cement bricks offer superior strength and durability, making them ideal for load-bearing structures, while fly ash bricks provide excellent thermal insulation and eco-friendliness due to recycled materials. Your choice depends on project requirements such as structural load, environmental considerations, and budget constraints. Evaluating these factors ensures you select the right brick for long-lasting, sustainable construction.

Cement Brick vs Fly Ash Brick Infographic

libmatt.com

libmatt.com