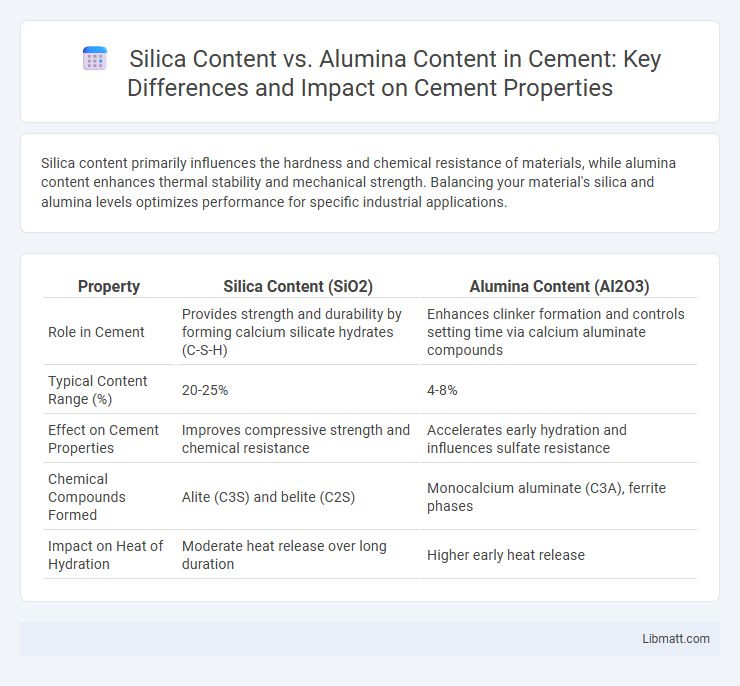

Silica content primarily influences the hardness and chemical resistance of materials, while alumina content enhances thermal stability and mechanical strength. Balancing your material's silica and alumina levels optimizes performance for specific industrial applications.

Table of Comparison

| Property | Silica Content (SiO2) | Alumina Content (Al2O3) |

|---|---|---|

| Role in Cement | Provides strength and durability by forming calcium silicate hydrates (C-S-H) | Enhances clinker formation and controls setting time via calcium aluminate compounds |

| Typical Content Range (%) | 20-25% | 4-8% |

| Effect on Cement Properties | Improves compressive strength and chemical resistance | Accelerates early hydration and influences sulfate resistance |

| Chemical Compounds Formed | Alite (C3S) and belite (C2S) | Monocalcium aluminate (C3A), ferrite phases |

| Impact on Heat of Hydration | Moderate heat release over long duration | Higher early heat release |

Understanding Silica and Alumina: Basic Definitions

Silica, primarily composed of silicon dioxide (SiO2), is a key compound found in sand, quartz, and many minerals, essential for forming glass, ceramics, and concrete. Alumina, or aluminum oxide (Al2O3), is crucial in ceramics and refractory materials due to its high melting point and hardness. Understanding your material's silica and alumina content helps determine its suitability for industrial applications such as construction, metallurgy, and manufacturing.

Importance of Silica and Alumina in Industrial Applications

Silica and alumina are critical components in numerous industrial applications due to their unique chemical and physical properties. Silica enhances thermal stability, hardness, and resistance to abrasion in materials such as glass, ceramics, and refractories, while alumina contributes exceptional strength, corrosion resistance, and electrical insulation in catalysts, abrasives, and advanced ceramics. Your selection between silica content and alumina content directly impacts the durability, efficiency, and performance of industrial products tailored to specific operational demands.

Chemical Properties: Silica vs Alumina

Silica (SiO2) exhibits high chemical stability and is resistant to most acids except hydrofluoric acid, making it ideal for applications requiring durability and inertness. Alumina (Al2O3) features strong acid-base amphoteric behavior, allowing it to react with both acids and bases, which enhances its versatility in catalysis and refractories. Understanding the chemical properties of silica and alumina helps optimize material selection based on their reactivity and stability in your specific industrial processes.

Sources and Natural Occurrence of Silica and Alumina

Silica primarily occurs in quartz, sand, and various silicate minerals found abundantly in the Earth's crust, forming the backbone of many igneous, sedimentary, and metamorphic rocks. Alumina is mainly sourced from bauxite, clay minerals, and feldspar, which are prevalent in tropical soils and continental crust formations. Understanding the natural occurrence of silica and alumina helps you assess their availability and influence in geological and industrial applications.

Methods of Measuring Silica and Alumina Content

Accurate measurement of silica and alumina content is critical in industries like ceramics, cement, and metallurgy. Common methods for determining silica content include gravimetric analysis, X-ray fluorescence (XRF), and inductively coupled plasma (ICP) spectroscopy, while alumina content is often measured using titration, XRF, and atomic absorption spectroscopy (AAS). You can optimize your material quality by selecting the appropriate analytical technique based on precision requirements, sample type, and instrument availability.

Impact of Silica-Alumina Ratio in Materials

The silica-alumina ratio critically influences the physicochemical properties of materials, affecting their thermal stability, acidity, and catalytic performance. Higher silica content typically enhances thermal stability and hydrophobicity, while increased alumina levels improve acidity and ion-exchange capacity, essential for catalysis applications such as zeolites and clays. Optimizing the silica-alumina ratio tailors material behavior for specific industrial uses, including petrochemical cracking and adsorption processes.

Performance Differences in Construction Materials

Higher silica content in construction materials typically enhances hardness, chemical resistance, and durability, making them ideal for high-strength concrete and refractory applications. Increased alumina content improves thermal stability and abrasion resistance, beneficial for fire-resistant bricks and castables. Balancing silica and alumina contents optimizes performance by tailoring strength, thermal properties, and longevity to specific construction needs.

Effect on Thermal and Mechanical Properties

Higher silica content typically enhances thermal resistance and reduces thermal expansion, making materials more stable at elevated temperatures, while increased alumina content improves mechanical strength and hardness due to its strong ionic bonds. The balance between silica and alumina directly influences the durability, thermal shock resistance, and wear properties of ceramics and glass, essential for optimizing performance in high-temperature applications. Understanding the precise ratio of silica to alumina can help you tailor materials to achieve the desired combination of thermal stability and mechanical robustness.

Environmental Implications of Silica and Alumina Use

Silica and alumina content directly influence the environmental impact of materials, with high silica levels often associated with increased energy consumption due to higher melting points in industrial processes. Alumina, while essential for catalytic and refractory applications, can lead to environmental concerns when mining disrupts ecosystems and generates hazardous waste. Understanding the balance between silica and alumina in Your materials helps optimize energy efficiency and minimize ecological footprints during production and disposal.

Future Trends in Silica and Alumina Research

Future trends in silica and alumina research emphasize the development of advanced composite materials with optimized silica and alumina content to enhance thermal stability and mechanical strength. Researchers are exploring nanoscale modifications to improve catalytic efficiency and adsorption properties, leveraging the unique interactions between silica and alumina phases. Your access to cutting-edge studies on silica-alumina ratios will enable innovative applications in catalysis, ceramics, and environmental remediation.

Silica content vs Alumina content Infographic

libmatt.com

libmatt.com