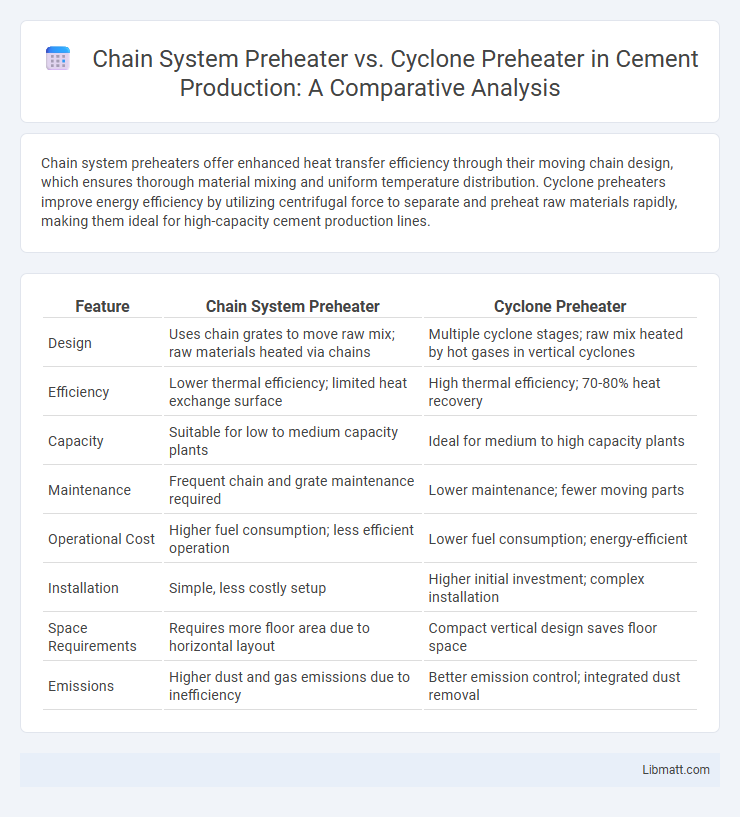

Chain system preheaters offer enhanced heat transfer efficiency through their moving chain design, which ensures thorough material mixing and uniform temperature distribution. Cyclone preheaters improve energy efficiency by utilizing centrifugal force to separate and preheat raw materials rapidly, making them ideal for high-capacity cement production lines.

Table of Comparison

| Feature | Chain System Preheater | Cyclone Preheater |

|---|---|---|

| Design | Uses chain grates to move raw mix; raw materials heated via chains | Multiple cyclone stages; raw mix heated by hot gases in vertical cyclones |

| Efficiency | Lower thermal efficiency; limited heat exchange surface | High thermal efficiency; 70-80% heat recovery |

| Capacity | Suitable for low to medium capacity plants | Ideal for medium to high capacity plants |

| Maintenance | Frequent chain and grate maintenance required | Lower maintenance; fewer moving parts |

| Operational Cost | Higher fuel consumption; less efficient operation | Lower fuel consumption; energy-efficient |

| Installation | Simple, less costly setup | Higher initial investment; complex installation |

| Space Requirements | Requires more floor area due to horizontal layout | Compact vertical design saves floor space |

| Emissions | Higher dust and gas emissions due to inefficiency | Better emission control; integrated dust removal |

Introduction to Cement Preheaters

Cement preheaters are essential components in the cement manufacturing process, enhancing thermal efficiency by preheating raw materials before entering the kiln. Chain system preheaters use chains to suspend and move raw meal, offering uniform heat distribution but generally lower throughput compared to cyclone preheaters. Cyclone preheaters consist of multiple cyclone stages that separate and preheat raw feed using hot kiln gases, providing higher efficiency and capacity in modern cement plants.

Overview of Chain System Preheater

Chain System Preheaters utilize a series of chain flights to lift hot gases and solids, enhancing heat exchange efficiency in cement production. This system offers improved uniform heating and reduced gas bypass compared to conventional Cyclone Preheaters, optimizing thermal energy utilization. You benefit from increased productivity and lower fuel consumption due to the enhanced heat transfer properties of the Chain System Preheater.

Overview of Cyclone Preheater

Cyclone Preheaters are highly efficient heat exchangers used in cement production to preheat raw materials before entering the kiln, utilizing centrifugal force to separate particles and gases. They typically achieve higher thermal efficiency compared to Chain System Preheaters, reducing fuel consumption and improving overall process performance. Your cement plant can benefit from faster heat transfer and lower emissions with the advanced design of Cyclone Preheaters.

Working Principles: Chain vs Cyclone Preheaters

Chain system preheaters operate by using chains attached to a rotating drum to lift and cascade raw meal through hot gases, enhancing heat exchange efficiency through direct contact. Cyclone preheaters utilize a series of cyclone separators that spin the raw meal, creating centrifugal force to maximize gas-solid contact and improve preheating capacity. The chain system offers simplicity and better handling of coarse materials, whereas cyclone preheaters provide higher thermal efficiency and lower energy consumption in cement production.

Heat Exchange Efficiency Comparison

Chain system preheaters typically exhibit lower heat exchange efficiency due to limited gas-solid contact and shorter residence times, resulting in less effective thermal energy transfer. Cyclone preheaters enhance heat exchange efficiency by utilizing high-velocity cyclonic motion, increasing gas-solid interaction and promoting rapid heat transfer to raw materials. Studies indicate cyclone preheaters can achieve heat exchange efficiencies exceeding 85%, outperforming chain systems which generally operate below 75% efficiency.

Energy Consumption and Cost Analysis

Chain system preheaters typically exhibit higher energy consumption due to lower heat recovery efficiency compared to cyclone preheaters, which capitalize on multiple cyclone stages to enhance heat exchange. The energy cost savings in cyclone preheaters arise from reduced fuel usage and improved thermal efficiency, contributing to lower operational expenses over time. Initial investment for cyclone preheaters is generally higher, but the long-term cost benefits driven by energy conservation often justify the upfront expenditure.

Environmental Impact and Emissions

Chain System Preheaters generally produce higher emissions of particulate matter and nitrogen oxides compared to Cyclone Preheaters due to less efficient heat exchange and incomplete combustion. Cyclone Preheaters offer superior environmental performance by promoting better fuel combustion and reducing carbon dioxide and sulfur oxide emissions, significantly lowering your plant's overall environmental footprint. Selecting a Cyclone Preheater can help your facility meet stricter emissions regulations and improve sustainability efforts.

Maintenance and Operational Complexity

Chain system preheaters require frequent maintenance due to higher wear and tear caused by moving parts, leading to increased downtime and operational complexity. Cyclone preheaters offer improved efficiency with fewer mechanical components, resulting in lower maintenance demands and simplified operation. Your choice depends on balancing maintenance capabilities with the desired process reliability and performance.

Suitability for Different Raw Materials

Chain system preheaters excel in processing raw materials with high moisture content and small particle size due to their efficient heat transfer and gentle material handling. Cyclone preheaters are better suited for coarser, dry raw materials, providing rapid heat exchange and improved fuel efficiency through high-temperature gas contact. Selecting the right preheater depends on your raw material characteristics, optimizing thermal performance and cement quality.

Future Trends in Preheater Technology

Chain system preheaters are evolving with enhanced energy efficiency and integration of smart sensors for real-time monitoring, predicting maintenance needs while reducing emissions. Cyclone preheaters are advancing through modular designs and adaptable configurations, supporting alternative fuels and improving thermal performance to meet stricter environmental regulations. Future trends emphasize digitalization, automation, and the incorporation of sustainable practices in both preheater systems to optimize cement production processes.

Chain System Preheater vs Cyclone Preheater Infographic

libmatt.com

libmatt.com