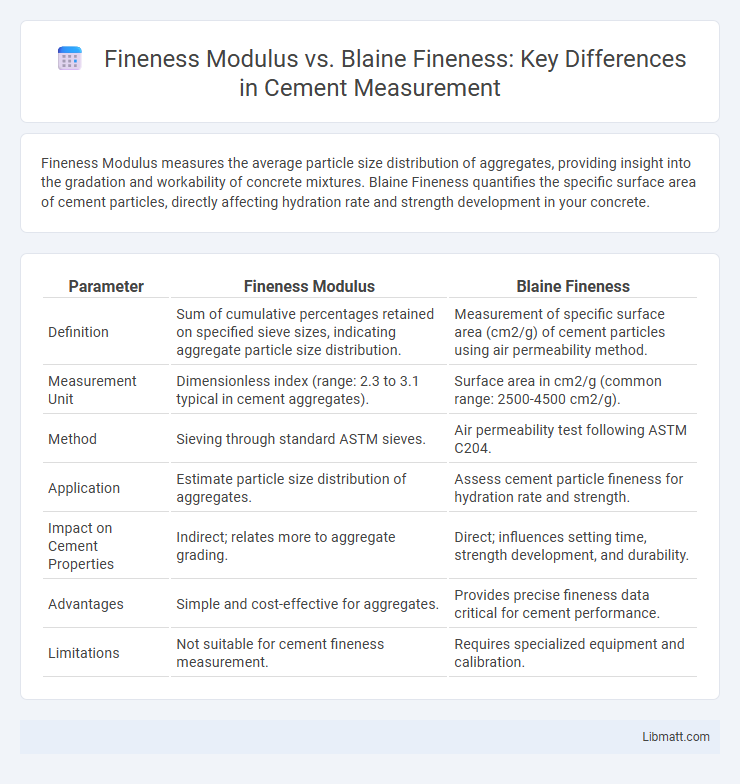

Fineness Modulus measures the average particle size distribution of aggregates, providing insight into the gradation and workability of concrete mixtures. Blaine Fineness quantifies the specific surface area of cement particles, directly affecting hydration rate and strength development in your concrete.

Table of Comparison

| Parameter | Fineness Modulus | Blaine Fineness |

|---|---|---|

| Definition | Sum of cumulative percentages retained on specified sieve sizes, indicating aggregate particle size distribution. | Measurement of specific surface area (cm2/g) of cement particles using air permeability method. |

| Measurement Unit | Dimensionless index (range: 2.3 to 3.1 typical in cement aggregates). | Surface area in cm2/g (common range: 2500-4500 cm2/g). |

| Method | Sieving through standard ASTM sieves. | Air permeability test following ASTM C204. |

| Application | Estimate particle size distribution of aggregates. | Assess cement particle fineness for hydration rate and strength. |

| Impact on Cement Properties | Indirect; relates more to aggregate grading. | Direct; influences setting time, strength development, and durability. |

| Advantages | Simple and cost-effective for aggregates. | Provides precise fineness data critical for cement performance. |

| Limitations | Not suitable for cement fineness measurement. | Requires specialized equipment and calibration. |

Introduction to Fineness Modulus and Blaine Fineness

Fineness Modulus is a numerical index representing the average particle size of aggregates, calculated by adding the cumulative percentages retained on a series of sieves and dividing the sum by 100. Blaine Fineness measures the specific surface area of cement particles in square centimeters per gram, determined using air permeability techniques to assess cement's ability to hydrate and gain strength. Both parameters critically influence concrete properties, with Fineness Modulus affecting workability and Blaine Fineness impacting cement reactivity and setting time.

Definition of Fineness Modulus

Fineness Modulus (FM) is an aggregate grading index calculated by adding the cumulative percentages retained on standard sieves and dividing the sum by 100, providing an estimate of the average particle size of the aggregate. Unlike Blaine Fineness, which measures the specific surface area of powdered materials like cement, FM primarily assesses the coarseness or fineness of sand and aggregate particles. This index is widely used in construction to control and optimize concrete mix proportions for desired workability and strength.

Definition of Blaine Fineness

Blaine Fineness measures the specific surface area of cement particles expressed in square centimeters per gram, determined by air permeability tests using the Blaine apparatus. Unlike the Fineness Modulus, a sieve-based index indicating particle size distribution, Blaine Fineness provides a more precise evaluation of cement reactivity and hydration rate. This parameter is crucial in controlling cement quality and optimizing strength development in concrete mixtures.

Measurement Methods: Sieve Analysis vs Air Permeability

Fineness Modulus (FM) is determined using sieve analysis, where aggregates pass through a series of sieves and the cumulative percentage retained is used to calculate the FM, indicating particle size distribution. Blaine Fineness measures the specific surface area of cement particles via air permeability methods, assessing how easily air passes through a compacted powder bed to estimate fineness and its impact on hydration rate. Understanding these measurement methods helps you select the appropriate parameter for evaluating granular materials or cement fineness in construction quality control.

Material Applications for Each Fineness Metric

Fineness Modulus (FM) primarily applies to aggregates in concrete mix design, indicating the average particle size which affects workability, strength, and durability of structures. Blaine Fineness measures the specific surface area of cement particles, crucial for predicting hydration rate and strength development in cementitious materials like Portland cement and supplementary cementitious materials. Your choice between these metrics depends on whether aggregate gradation or cement particle fineness is critical for optimizing material performance in concrete or cement applications.

Impact on Concrete and Cement Properties

Fineness modulus and Blaine fineness are critical parameters influencing concrete and cement properties; finer cement particles with higher Blaine fineness improve hydration rate, enhancing early strength development and durability. A higher fineness modulus typically signifies coarser aggregates, affecting workability and reducing concrete density, which can impact compressive strength negatively. Optimizing both parameters ensures balanced performance, tailoring concrete mix for specific structural requirements and longevity.

Comparative Table: Fineness Modulus vs Blaine Fineness

| Parameter | Fineness Modulus (FM) | Blaine Fineness | |----------------------|--------------------------------------|------------------------------------------| | Measurement Basis | Sieve analysis of aggregate particle size distribution | Air permeability test measuring surface area of cement particles | | Typical Application | Aggregate gradation in concrete mix design | Cement particle fineness affecting hydration rate and strength development | | Units | Dimensionless index (sum of cumulative percentages retained divided by 100) | cm2/g or m2/kg (specific surface area) | | Influence on Material | Indicates coarseness or fineness of aggregates impacting workability | Indicates cement particle size affecting water demand and setting time | | Testing Method | Sieving aggregates through standard sieves | Blaine air permeability apparatus |

Advantages and Limitations of Each Method

Fineness Modulus (FM) provides a simple aggregate particle size distribution measure, enabling quick quality control but lacks precision in predicting cement hydration rates. Blaine Fineness offers a more detailed assessment of cement particle surface area, directly correlating with reactivity and strength development but requires specialized equipment and longer testing times. FM is advantageous for general aggregate grading, whereas Blaine Fineness is preferred for optimizing cement performance in advanced concrete formulations.

Industry Standards and Typical Values

Fineness Modulus (FM) and Blaine Fineness are critical industry standards used to evaluate the particle size distribution and specific surface area of cement and aggregates, respectively. Typical FM values range from 2.3 to 3.1 for fine aggregates, indicating the gradation and texture quality, while Blaine Fineness values for cement usually span between 3000 and 4500 cm2/g, reflecting the material's fineness impacting hydration rates and strength development. Your project's material quality can be optimized by selecting aggregates and cement within these standard ranges to ensure compliance with construction norms and performance expectations.

Conclusion: Choosing the Right Fineness Metric

Choosing the right fineness metric depends on the specific application and material characteristics. Fineness Modulus offers a weighted average particle size useful for aggregates, while Blaine Fineness measures the specific surface area of cement particles, critical for hydration rates. Your selection impacts mix design and performance, making it essential to align the metric with the testing purpose and desired material properties.

Fineness Modulus vs Blaine Fineness Infographic

libmatt.com

libmatt.com