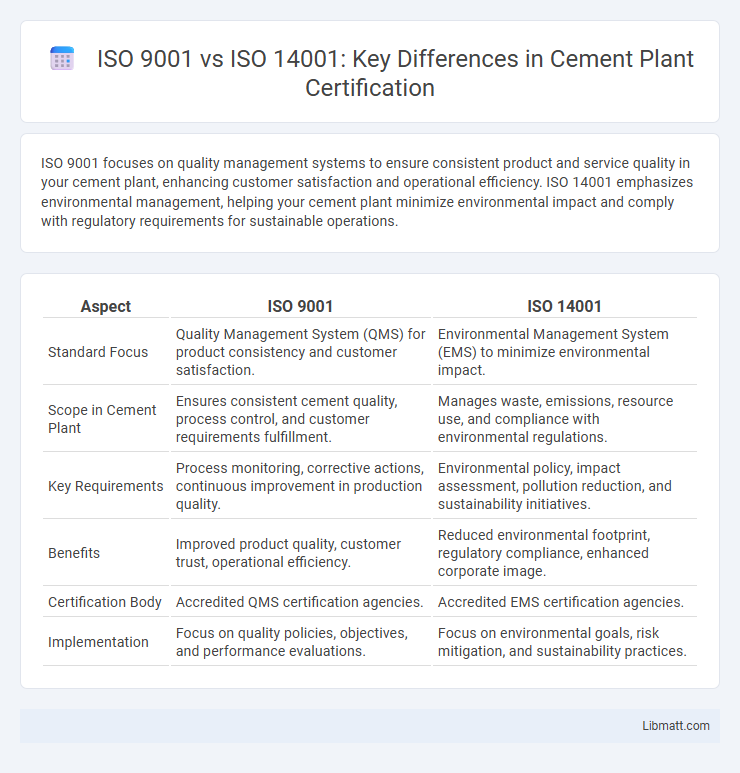

ISO 9001 focuses on quality management systems to ensure consistent product and service quality in your cement plant, enhancing customer satisfaction and operational efficiency. ISO 14001 emphasizes environmental management, helping your cement plant minimize environmental impact and comply with regulatory requirements for sustainable operations.

Table of Comparison

| Aspect | ISO 9001 | ISO 14001 |

|---|---|---|

| Standard Focus | Quality Management System (QMS) for product consistency and customer satisfaction. | Environmental Management System (EMS) to minimize environmental impact. |

| Scope in Cement Plant | Ensures consistent cement quality, process control, and customer requirements fulfillment. | Manages waste, emissions, resource use, and compliance with environmental regulations. |

| Key Requirements | Process monitoring, corrective actions, continuous improvement in production quality. | Environmental policy, impact assessment, pollution reduction, and sustainability initiatives. |

| Benefits | Improved product quality, customer trust, operational efficiency. | Reduced environmental footprint, regulatory compliance, enhanced corporate image. |

| Certification Body | Accredited QMS certification agencies. | Accredited EMS certification agencies. |

| Implementation | Focus on quality policies, objectives, and performance evaluations. | Focus on environmental goals, risk mitigation, and sustainability practices. |

Introduction to ISO 9001 and ISO 14001 in Cement Plants

ISO 9001 sets the global standard for quality management systems, ensuring cement plants consistently meet customer and regulatory requirements while enhancing operational efficiency. ISO 14001 focuses on environmental management, helping cement plants minimize their ecological impact through systematic processes and sustainable practices. Your cement plant's certification in both standards demonstrates commitment to product quality and environmental responsibility, boosting market competitiveness and regulatory compliance.

Key Differences Between ISO 9001 and ISO 14001

ISO 9001 focuses on quality management systems, emphasizing product consistency and customer satisfaction within cement plant operations, whereas ISO 14001 targets environmental management, prioritizing sustainable practices and regulatory compliance. The certification process for ISO 9001 involves improving process efficiency and defect reduction, while ISO 14001 certification drives the implementation of environmental policies and impact mitigation. Key differentiators include ISO 9001's focus on quality control and continuous improvement, contrasting with ISO 14001's framework for minimizing environmental footprints and enhancing resource management in cement plants.

Scope and Objectives of ISO 9001 for Cement Manufacturing

ISO 9001 certification for cement manufacturing focuses on establishing a Quality Management System (QMS) that ensures consistent production of high-quality cement by optimizing processes, reducing defects, and enhancing customer satisfaction. The scope includes design control, raw material inspection, production monitoring, and delivery performance, aiming to meet regulatory requirements and client specifications. This standard drives continuous improvement and operational efficiency throughout all stages of cement production, from quarrying to dispatch.

Scope and Objectives of ISO 14001 for Cement Plants

ISO 14001 certification for cement plants focuses on establishing an effective environmental management system that minimizes the plant's ecological footprint by controlling emissions, waste, and resource consumption. Its scope includes the identification and mitigation of environmental risks associated with cement production processes, ensuring compliance with relevant environmental regulations and continuous improvement in sustainability practices. Your cement plant benefits from enhanced environmental performance, reduced operational costs, and improved stakeholder confidence through adherence to ISO 14001 standards.

Quality Management vs Environmental Management Systems

ISO 9001 focuses on Quality Management Systems (QMS) by establishing standardized processes that enhance product consistency, customer satisfaction, and operational efficiency in cement plants. ISO 14001 targets Environmental Management Systems (EMS), guiding cement plants to minimize environmental impact through sustainable practices, resource conservation, and regulatory compliance. Both certifications promote continuous improvement, but ISO 9001 prioritizes quality control and process optimization, while ISO 14001 emphasizes environmental responsibility and pollution prevention.

Core Requirements of ISO 9001 in Cement Industry

ISO 9001 certification for cement plants emphasizes establishing a robust quality management system focused on consistent product quality, customer satisfaction, and continual improvement of operational processes. Core requirements include documented procedures for process control, regular internal audits, corrective actions for non-conformities, and top management commitment to quality objectives. This standard ensures the cement industry maintains high standards in production accuracy, meeting regulatory compliance, and enhancing overall efficiency.

Core Requirements of ISO 14001 in Cement Industry

ISO 14001 certification for cement plants primarily focuses on establishing an effective environmental management system that controls emissions, waste, and resource consumption. Core requirements include compliance with environmental legislation, continuous improvement of environmental performance, and effective pollution prevention measures tailored to the cement industry's impact. You can achieve sustainable operations and regulatory adherence by integrating these environmental standards into your cement plant's processes.

Benefits of ISO 9001 Certification for Cement Plants

ISO 9001 certification enhances cement plants by standardizing quality management systems, leading to improved product consistency and customer satisfaction. This certification helps your plant reduce operational inefficiencies and increase process reliability, ultimately boosting competitive advantage. Implementing ISO 9001 also facilitates regulatory compliance and fosters continuous improvement in production and service quality.

Benefits of ISO 14001 Certification for Cement Plants

ISO 14001 certification provides cement plants with a structured framework to enhance environmental management, reduce waste, and lower energy consumption, leading to significant cost savings. The standard improves compliance with environmental regulations, minimizing risks of fines and enhancing the plant's reputation among stakeholders and communities. Your commitment to ISO 14001 demonstrates environmental responsibility, improving market competitiveness and supporting sustainable growth in the cement industry.

Choosing the Right Standard: ISO 9001, ISO 14001, or Both?

Selecting the appropriate certification for a cement plant depends on whether the focus is on quality management or environmental impact, with ISO 9001 emphasizing consistent product quality and customer satisfaction, while ISO 14001 targets environmental responsibility and sustainable practices. Many cement plants pursue both ISO 9001 and ISO 14001 certifications simultaneously to ensure comprehensive management systems that enhance operational efficiency and minimize ecological footprint. Integrating both standards supports improved regulatory compliance, risk management, and stakeholder confidence in the plant's quality and environmental stewardship.

ISO 9001 vs ISO 14001 (Cement Plant Certification) Infographic

libmatt.com

libmatt.com