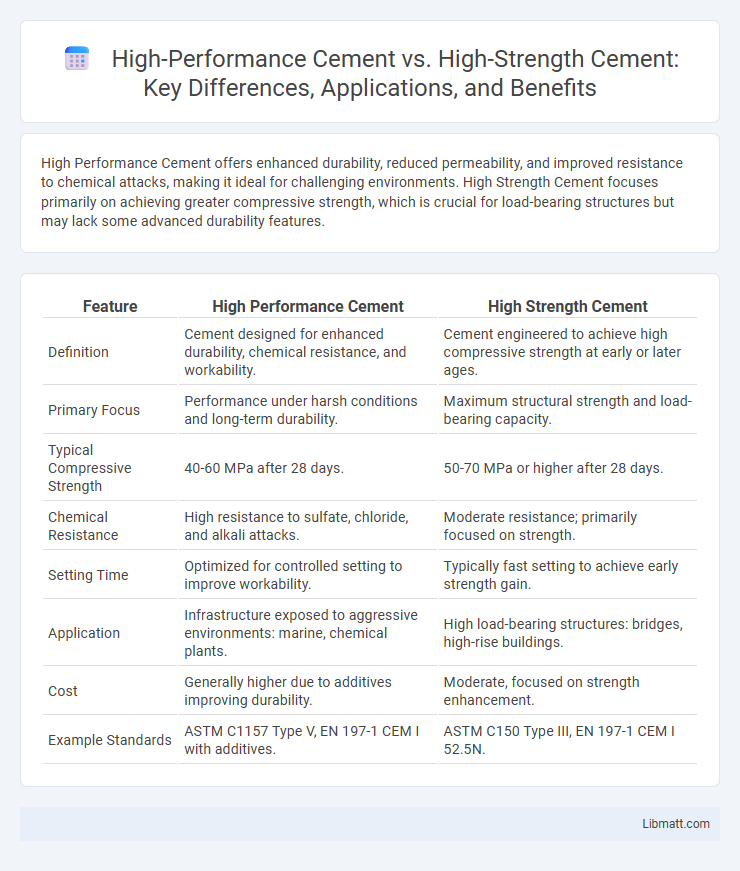

High Performance Cement offers enhanced durability, reduced permeability, and improved resistance to chemical attacks, making it ideal for challenging environments. High Strength Cement focuses primarily on achieving greater compressive strength, which is crucial for load-bearing structures but may lack some advanced durability features.

Table of Comparison

| Feature | High Performance Cement | High Strength Cement |

|---|---|---|

| Definition | Cement designed for enhanced durability, chemical resistance, and workability. | Cement engineered to achieve high compressive strength at early or later ages. |

| Primary Focus | Performance under harsh conditions and long-term durability. | Maximum structural strength and load-bearing capacity. |

| Typical Compressive Strength | 40-60 MPa after 28 days. | 50-70 MPa or higher after 28 days. |

| Chemical Resistance | High resistance to sulfate, chloride, and alkali attacks. | Moderate resistance; primarily focused on strength. |

| Setting Time | Optimized for controlled setting to improve workability. | Typically fast setting to achieve early strength gain. |

| Application | Infrastructure exposed to aggressive environments: marine, chemical plants. | High load-bearing structures: bridges, high-rise buildings. |

| Cost | Generally higher due to additives improving durability. | Moderate, focused on strength enhancement. |

| Example Standards | ASTM C1157 Type V, EN 197-1 CEM I with additives. | ASTM C150 Type III, EN 197-1 CEM I 52.5N. |

Introduction to High Performance Cement and High Strength Cement

High Performance Cement (HPC) offers enhanced durability, workability, and resistance to environmental stress, making it ideal for complex and demanding construction projects. High Strength Cement focuses primarily on achieving greater compressive strength, ensuring structural integrity in load-bearing applications. Understanding the distinct properties of each type allows you to select the best cement for your specific building requirements.

Defining High Performance Cement

High Performance Cement (HPC) is engineered to offer superior durability, workability, and environmental resistance compared to conventional cements, optimizing concrete performance under extreme conditions. Unlike High Strength Cement, which primarily emphasizes compressive strength, HPC balances multiple properties such as enhanced resistance to chemical attacks, reduced permeability, and improved mechanical behavior over time. These attributes make HPC a preferred choice for infrastructure projects requiring longevity and sustainability, including bridges, dams, and marine structures.

Defining High Strength Cement

High Strength Cement is defined by its ability to achieve compressive strengths typically above 50 MPa within 28 days, making it ideal for structural applications requiring enhanced load-bearing capacity. Unlike High Performance Cement, which emphasizes a combination of properties such as durability, workability, and resistance to chemical attack, High Strength Cement focuses primarily on achieving superior mechanical strength. Your construction projects benefit from choosing High Strength Cement when maximum durability and structural integrity are the primary objectives.

Key Differences between High Performance and High Strength Cement

High Performance Cement exhibits superior durability, resistance to chemical attacks, and enhanced workability compared to High Strength Cement, which primarily focuses on achieving higher compressive strength. The formulation of High Performance Cement integrates advanced additives and supplementary materials to improve properties such as permeability and setting time, whereas High Strength Cement emphasizes increased clinker content for maximum strength. The key difference lies in High Performance Cement's balanced approach to multiple performance criteria, while High Strength Cement concentrates mainly on mechanical strength.

Chemical Composition Comparison

High Performance Cement (HPC) typically contains supplementary cementitious materials like fly ash, silica fume, and slag, enhancing durability and chemical resistance, whereas High Strength Cement (HSC) primarily focuses on high clinker content for increased compressive strength. HPC exhibits a balanced calcium silicate hydrate (C-S-H) gel structure due to pozzolanic reactions, reducing calcium hydroxide content and improving long-term stability. In contrast, HSC's chemical composition is optimized for rapid strength gain through elevated tricalcium silicate (C3S) levels, leading to a denser matrix but potentially less chemical durability compared to HPC.

Mechanical Properties and Performance

High Performance Cement exhibits superior durability, enhanced chemical resistance, and improved workability compared to High Strength Cement, which primarily focuses on achieving greater compressive strength often exceeding 60 MPa. The mechanical properties of High Performance Cement emphasize reduced permeability and resistance to environmental degradation, leading to longer service life in aggressive conditions. High Strength Cement delivers exceptional load-bearing capacity but may lack the specialized performance characteristics critical for infrastructure exposed to harsh chemical or physical stress.

Applications and Use Cases

High Performance Cement is ideal for infrastructure projects requiring durability and resistance to chemical attacks, such as bridges, tunnels, and marine structures. High Strength Cement is typically used in construction requiring superior load-bearing capacity, including high-rise buildings and heavy industrial floors. Selecting the appropriate cement type depends on project-specific requirements like environmental exposure and structural demands.

Durability and Longevity Factors

High Performance Cement offers superior durability due to its enhanced resistance to chemical attacks, reduced permeability, and improved microstructure, which significantly extends the lifespan of concrete structures. High Strength Cement primarily emphasizes compressive strength but may not provide the same level of durability under harsh environmental conditions. Selecting High Performance Cement is ideal for projects requiring long-term resilience against weathering, sulfate exposure, and freeze-thaw cycles, ensuring greater structural longevity.

Cost Considerations and Economic Impact

High Performance Cement typically incurs higher initial costs than High Strength Cement due to advanced formulations and specialized additives that enhance durability and longevity. Despite the higher upfront investment, High Performance Cement can lead to significant long-term savings by reducing maintenance, repair expenses, and extending the service life of structures. In contrast, High Strength Cement offers a more cost-effective solution for projects prioritizing rapid strength gain, balancing material costs with shorter construction timelines and earlier load application.

Choosing the Right Cement for Your Project

High Performance Cement offers enhanced durability, resistance to chemical attacks, and improved workability, making it ideal for infrastructure projects requiring long-term stability. High Strength Cement emphasizes achieving higher compressive strength quickly, suitable for structural applications where load-bearing capacity is critical. Selecting the right cement depends on project demands such as durability requirements and strength criteria, ensuring optimal performance and longevity.

High Performance Cement vs High Strength Cement Infographic

libmatt.com

libmatt.com