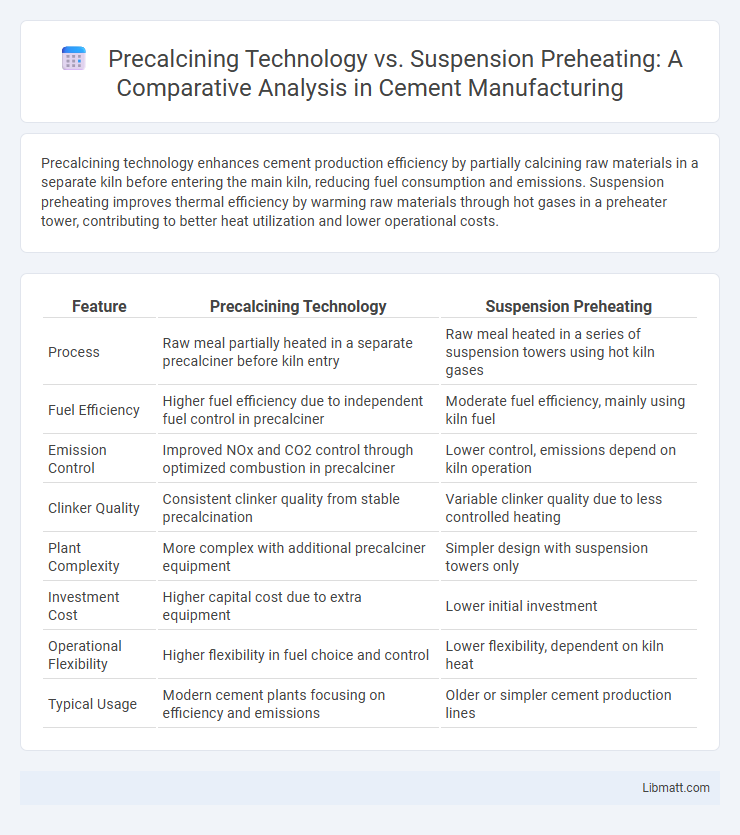

Precalcining technology enhances cement production efficiency by partially calcining raw materials in a separate kiln before entering the main kiln, reducing fuel consumption and emissions. Suspension preheating improves thermal efficiency by warming raw materials through hot gases in a preheater tower, contributing to better heat utilization and lower operational costs.

Table of Comparison

| Feature | Precalcining Technology | Suspension Preheating |

|---|---|---|

| Process | Raw meal partially heated in a separate precalciner before kiln entry | Raw meal heated in a series of suspension towers using hot kiln gases |

| Fuel Efficiency | Higher fuel efficiency due to independent fuel control in precalciner | Moderate fuel efficiency, mainly using kiln fuel |

| Emission Control | Improved NOx and CO2 control through optimized combustion in precalciner | Lower control, emissions depend on kiln operation |

| Clinker Quality | Consistent clinker quality from stable precalcination | Variable clinker quality due to less controlled heating |

| Plant Complexity | More complex with additional precalciner equipment | Simpler design with suspension towers only |

| Investment Cost | Higher capital cost due to extra equipment | Lower initial investment |

| Operational Flexibility | Higher flexibility in fuel choice and control | Lower flexibility, dependent on kiln heat |

| Typical Usage | Modern cement plants focusing on efficiency and emissions | Older or simpler cement production lines |

Introduction to Cement Kiln Technologies

Precalcining technology significantly reduces energy consumption in cement kiln processes by partially calcining raw materials before entering the rotary kiln, enhancing thermal efficiency. Suspension preheating involves heating raw mix particles suspended in hot gases, improving heat exchange and reducing fuel use during clinker formation. Both technologies optimize temperature control and fuel efficiency, enabling higher production capacity and reducing emissions in modern cement manufacturing.

Overview of Precalcining Technology

Precalcining technology involves the thermal decomposition of raw materials, typically within a precalciner, to remove carbon dioxide before entering the kiln, enhancing energy efficiency and reducing emissions. This process achieves high-calcium conversion rates by maintaining temperatures around 900degC to 1000degC, optimizing fuel consumption compared to traditional suspension preheating methods. Industrial applications benefit from increased throughput and improved clinker quality due to better control of the calcination stage.

Principles of Suspension Preheating

Suspension preheating operates by suspending raw materials in hot gases, allowing particles to absorb heat efficiently before entering the kiln. This process enhances thermal transfer through increased surface area exposure and turbulent flow within the preheater tower, improving combustion efficiency. You benefit from reduced fuel consumption and lower emissions compared to traditional precalcining technology, owing to optimized heat recovery and shorter retention times.

Key Differences Between Precalcining and Suspension Preheating

Precalcining technology involves partial calcination of raw meal in a separate precalciner before entering the rotary kiln, boosting thermal efficiency and clinker production by enabling higher throughput and lower fuel consumption. Suspension preheating suspends raw meal particles in hot gases within a multi-stage cyclone preheater to raise temperature before kiln entry, primarily focusing on energy recovery and uniform heating but without decomposing carbonates significantly. The key differences lie in calcination stage completion, energy optimization, and process integration, where precalcining achieves early calcination and higher output, while suspension preheating optimizes heat exchange without extensive chemical transformation.

Energy Efficiency Comparison

Precalcining technology significantly outperforms suspension preheating in energy efficiency by enabling fuel combustion within the precalciner, reducing heat loss and lowering specific fuel consumption. Suspension preheating relies primarily on indirect heat transfer, leading to higher energy usage and increased thermal inefficiencies. The targeted fuel introduction in precalcining reduces overall greenhouse gas emissions, making it a more sustainable and cost-effective choice for cement production.

Impact on Clinker Quality

Precalcining technology offers superior control over combustion conditions, resulting in more consistent clinker mineralogy and enhanced reactivity compared to suspension preheating. Suspension preheating may lead to uneven temperature distribution, causing variability in clinker phase formation and potential strength inconsistencies. Optimizing heat transfer and residence time in precalcining systems significantly improves clinker quality by promoting complete fuel combustion and uniform clinker chemistry.

Environmental Considerations

Precalcining technology offers significant environmental benefits by reducing fuel consumption and lowering CO2 emissions compared to suspension preheating, thanks to its efficient heat recovery and combustion process. Suspension preheating generates higher particulate emissions due to incomplete fuel combustion, impacting air quality adversely. Your choice of precalcining technology can contribute to greener cement production by minimizing environmental pollutants and improving energy efficiency.

Operational Costs and Maintenance

Precalcining technology reduces operational costs by enhancing fuel efficiency and lowering thermal energy consumption compared to suspension preheating, which typically demands higher energy input for consistent heat distribution. Maintenance in precalcining systems is more rigorous due to increased mechanical complexity and exposure to high-temperature calcination environments, whereas suspension preheating offers simpler maintenance with less wear on components. The balance between cost savings in fuel and increased maintenance complexity makes precalcining advantageous for large-scale cement production facilities aiming for long-term efficiency gains.

Technological Advancements and Innovations

Precalcining technology has advanced with the integration of modular precalciner designs and improved combustion control, enhancing fuel efficiency and reducing emissions in cement production. Suspension preheating innovations focus on higher cyclonic efficiency and optimized gas-solid contact, enabling faster heat transfer and lower energy consumption. Both technologies benefit from real-time monitoring systems and AI-driven process controls, increasing operational stability and adapting dynamically to varying raw material properties.

Future Trends in Cement Kiln Design

Future trends in cement kiln design emphasize increasing energy efficiency and reducing emissions by integrating advanced precalcining technology, which enhances fuel utilization and accelerates clinker formation. Suspension preheating remains vital for achieving optimal heat exchange, but emerging designs focus on combining both methods to maximize thermal performance and minimize environmental impact. Your choice of kiln system will benefit from innovations in real-time process monitoring and adaptive control, ensuring sustainable cement production aligned with global regulatory standards.

Precalcining Technology vs Suspension Preheating Infographic

libmatt.com

libmatt.com