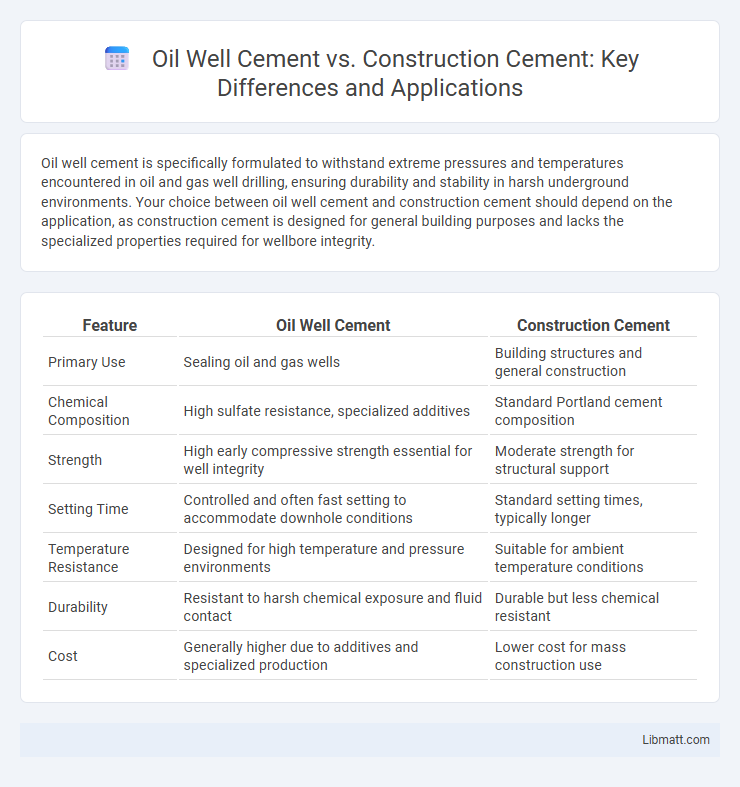

Oil well cement is specifically formulated to withstand extreme pressures and temperatures encountered in oil and gas well drilling, ensuring durability and stability in harsh underground environments. Your choice between oil well cement and construction cement should depend on the application, as construction cement is designed for general building purposes and lacks the specialized properties required for wellbore integrity.

Table of Comparison

| Feature | Oil Well Cement | Construction Cement |

|---|---|---|

| Primary Use | Sealing oil and gas wells | Building structures and general construction |

| Chemical Composition | High sulfate resistance, specialized additives | Standard Portland cement composition |

| Strength | High early compressive strength essential for well integrity | Moderate strength for structural support |

| Setting Time | Controlled and often fast setting to accommodate downhole conditions | Standard setting times, typically longer |

| Temperature Resistance | Designed for high temperature and pressure environments | Suitable for ambient temperature conditions |

| Durability | Resistant to harsh chemical exposure and fluid contact | Durable but less chemical resistant |

| Cost | Generally higher due to additives and specialized production | Lower cost for mass construction use |

Introduction to Oil Well Cement and Construction Cement

Oil well cement is specifically formulated for the high-pressure, high-temperature environments encountered in oil and gas well construction, featuring additives that enhance strength, durability, and resistance to chemical attack. Construction cement, commonly known as Portland cement, is designed for general building projects, providing structural integrity for concrete, mortar, and other construction materials under normal environmental conditions. Key differences lie in composition and performance requirements, where oil well cement includes classes and grades tailored to withstand subsurface pressures and temperatures not typical for construction cement.

Composition Differences: Oil Well vs Construction Cement

Oil well cement contains specialized additives such as retarders, accelerators, and weighting agents to withstand high pressure, temperature, and chemical exposure in subterranean environments. Construction cement, primarily Portland cement, features a simpler composition aimed at standard strength and curing properties suitable for buildings and infrastructure. Understanding these composition differences ensures your project uses the right cement type for durability and performance.

Key Applications: Industrial vs Structural Uses

Oil well cement is specifically engineered for industrial applications in the oil and gas sector, providing high compressive strength and resistance to extreme pressure and temperature conditions encountered during well drilling and completion. Construction cement, on the other hand, is primarily used in structural applications such as building foundations, bridges, and highways, where durability and workability in various environmental conditions are critical. The formulation differences enable oil well cement to withstand harsh subterranean environments, while construction cement optimizes structural integrity and longevity in above-ground infrastructure.

Performance Under Pressure and Temperature

Oil well cement is specially formulated to withstand extreme pressure and high temperatures encountered in deep drilling environments, maintaining its integrity and preventing well collapse. Construction cement, typically Portland cement, is designed for standard building applications and lacks the additives necessary for high-pressure and high-temperature resilience. The unique composition of oil well cement, including retarders and extenders, enhances its performance under aggressive downhole conditions where conventional construction cement would fail.

Setting Time and Hardening Properties

Oil well cement exhibits a controlled setting time engineered to withstand extreme downhole temperatures and pressures, typically ranging from delayed to normal set times depending on the formulation. Construction cement, such as Portland cement, generally has a faster set and hardening process suited for ambient conditions with setting times from 30 minutes to several hours. Hardening properties of oil well cement provide high compressive strength and durability in harsh environments, while construction cement hardens to achieve structural integrity under typical building applications.

Chemical Resistance and Durability

Oil well cement exhibits superior chemical resistance compared to construction cement due to its unique formulation designed to withstand harsh subterranean environments, including exposure to high concentrations of sulfates, chlorides, and acidic gases. The high durability of oil well cement is attributed to additives such as silica and special retarders that enhance its strength and prevent degradation over extended periods under extreme temperatures and pressures. Conversely, construction cement, while effective for general building purposes, lacks the specialized compounds necessary to endure chemically aggressive conditions, making it less suitable for oil well applications.

Standards and Certifications for Each Cement Type

Oil well cement adheres to stringent standards such as API Spec 10A and ASTM C150, ensuring durability and performance under high pressure and temperature conditions crucial for well integrity. Construction cement, commonly Portland cement, must meet standards like ASTM C150 and EN 197-1, focusing on strength, setting time, and compatibility with various construction materials. Understanding these certifications helps you select the appropriate cement type, optimizing safety and efficiency in your projects.

Environmental Impact Comparison

Oil well cement often contains additives that improve durability under high pressure and temperature conditions, but its production and use can result in higher carbon emissions and hazardous waste compared to construction cement. Construction cement typically has a lower environmental footprint due to standardized formulations and widespread recycling practices, yet it contributes significantly to global CO2 emissions during manufacturing. Sustainable alternatives and improved production technologies are essential to reduce the overall environmental impact of both types of cement in their respective industries.

Cost Considerations: Oil Well vs Construction Cement

Oil well cement typically incurs higher costs than construction cement due to its specialized chemical composition and enhanced durability required for high-pressure, high-temperature well environments. Construction cement is more economical, manufactured in larger quantities with standard formulations optimized for general building projects. The price difference reflects the stringent quality controls and additives in oil well cement essential for ensuring well integrity and preventing failure during drilling operations.

Choosing the Right Cement for Your Project

Oil well cement is specifically formulated to withstand high temperatures, pressures, and corrosive environments encountered in drilling operations, ensuring well integrity and zonal isolation. Construction cement, such as Portland cement, is designed for general building purposes, offering durability and strength for foundations, structures, and pavements under normal conditions. Choosing the right cement for your project depends on the environmental demands and performance requirements, with oil well cement being essential for subsurface applications and construction cement suited for surface construction tasks.

Oil well cement vs Construction cement Infographic

libmatt.com

libmatt.com