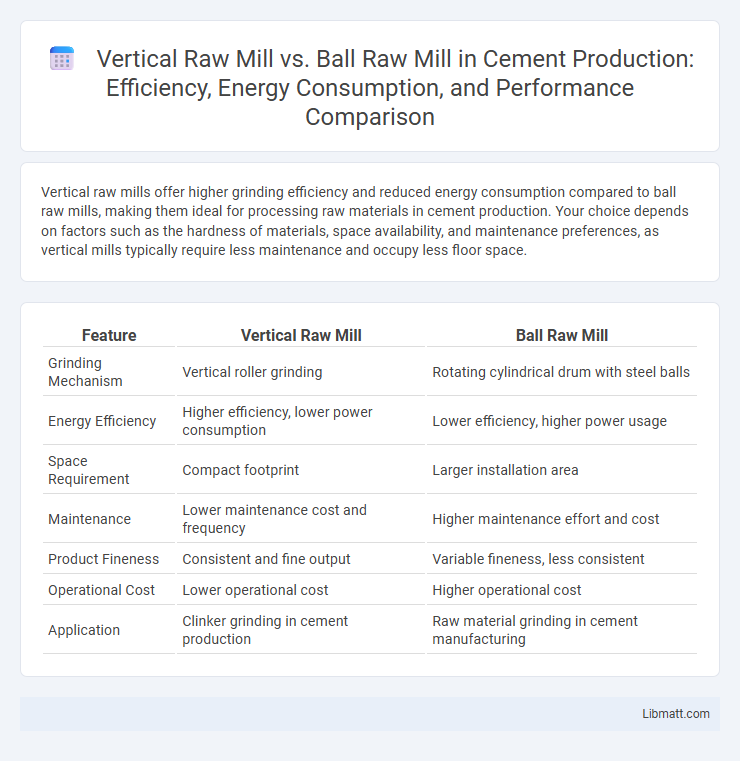

Vertical raw mills offer higher grinding efficiency and reduced energy consumption compared to ball raw mills, making them ideal for processing raw materials in cement production. Your choice depends on factors such as the hardness of materials, space availability, and maintenance preferences, as vertical mills typically require less maintenance and occupy less floor space.

Table of Comparison

| Feature | Vertical Raw Mill | Ball Raw Mill |

|---|---|---|

| Grinding Mechanism | Vertical roller grinding | Rotating cylindrical drum with steel balls |

| Energy Efficiency | Higher efficiency, lower power consumption | Lower efficiency, higher power usage |

| Space Requirement | Compact footprint | Larger installation area |

| Maintenance | Lower maintenance cost and frequency | Higher maintenance effort and cost |

| Product Fineness | Consistent and fine output | Variable fineness, less consistent |

| Operational Cost | Lower operational cost | Higher operational cost |

| Application | Clinker grinding in cement production | Raw material grinding in cement manufacturing |

Introduction to Raw Mills in Cement Production

Vertical Raw Mills and Ball Raw Mills are essential equipment in cement production for grinding raw materials into fine powder. The Vertical Raw Mill offers higher efficiency, lower energy consumption, and a smaller footprint compared to the traditional Ball Raw Mill, which relies on rotating cylinders filled with grinding media. Your choice depends on factors like capacity, energy use, and maintenance requirements crucial to optimizing the raw material grinding process.

Overview of Vertical Raw Mills

Vertical Raw Mills utilize rollers rotating on a vertical axis to crush and grind raw materials efficiently, leading to lower energy consumption and reduced maintenance compared to Ball Raw Mills. They offer a compact design with an integrated separator system, ensuring uniform particle size and consistent output quality in cement and mineral processing industries. You can achieve higher productivity and better grinding performance using Vertical Raw Mills, especially suitable for large-scale production.

Overview of Ball Raw Mills

Ball Raw Mills are cylindrical devices used in cement manufacturing to grind raw materials into fine powders, crucial for the clinker production process. Their rotating steel balls crush and grind the material, enabling uniform particle size distribution essential for efficient combustion in the kiln. You benefit from Ball Raw Mills' robust design and adaptability to different raw material types, ensuring consistent output and energy-efficient operation.

Key Design Differences: Vertical vs Ball Raw Mill

Vertical raw mills feature a vertical shaft and use pressure grinding on a rotating table, allowing simultaneous drying and grinding of raw materials, which enhances energy efficiency and reduces wear parts. Ball raw mills utilize a horizontal cylinder filled with grinding media, relying on tumbling action to crush raw materials, often resulting in longer retention time and higher energy consumption. Your choice between vertical and ball raw mills will impact operational efficiency, maintenance costs, and suitability for handling varying raw material moisture levels.

Energy Efficiency Comparison

Vertical raw mills demonstrate higher energy efficiency compared to ball raw mills by utilizing a grinding process that consumes significantly less power and reduces heat loss. The vertical mill's integrated drying, grinding, and separation system minimizes energy consumption, leading to savings of up to 30-40% compared to traditional ball mills. Optimizing your cement grinding process with a vertical raw mill can lower operational costs and improve energy performance substantially.

Grinding Performance and Product Quality

Vertical raw mills offer superior grinding performance by achieving finer particle size distribution with less energy consumption compared to ball raw mills. The enhanced grinding efficiency in vertical mills results in more uniform and higher-quality raw meal, which improves cement strength and kiln performance. Ball raw mills, while simpler in design, produce coarser particles and higher moisture content, potentially leading to reduced product quality and increased operational costs.

Operational and Maintenance Aspects

Vertical Raw Mills require less floor space and offer higher energy efficiency compared to Ball Raw Mills, reducing operational costs. Maintenance of Vertical Raw Mills is generally simpler due to fewer moving parts and easier accessibility, while Ball Raw Mills demand regular inspections and replacements of wear components such as liners and grinding media. You can optimize plant uptime by choosing a mill type that aligns with your maintenance capabilities and operational goals.

Environmental Impact and Sustainability

Vertical Raw Mills (VRMs) typically consume less energy and generate lower CO2 emissions compared to Ball Raw Mills due to their efficient grinding mechanisms, promoting better environmental sustainability. VRMs produce less noise and dust pollution, enhancing workplace safety and minimizing ecological disturbances. Choosing a Vertical Raw Mill for your operations supports cleaner production and aligns with green manufacturing goals.

Cost Considerations: Installation and Operation

Vertical raw mills generally require higher initial installation costs due to their complex design and specialized components, but they offer lower operational expenses by consuming less energy and requiring reduced maintenance. Ball raw mills incur lower upfront installation costs with simpler machinery but tend to have higher operational costs driven by greater power consumption and more frequent wear parts replacement. Evaluating these cost factors is crucial for optimizing long-term production efficiency and budget management in cement manufacturing.

Conclusion: Choosing the Right Raw Mill Technology

Choosing the right raw mill technology depends on your plant's specific operational needs, capacity requirements, and energy efficiency goals. Vertical raw mills offer higher energy efficiency, smaller footprints, and better drying capabilities, making them ideal for modern cement production with environmental considerations. Ball raw mills provide flexibility in grinding various materials but tend to consume more power and occupy more space, so your choice should align with your plant's performance priorities and long-term cost savings.

Vertical Raw Mill vs Ball Raw Mill Infographic

libmatt.com

libmatt.com