Slag cement is a supplementary cementitious material made from granulated blast furnace slag, enhancing durability and resistance to chemical attacks when mixed with ordinary Portland cement. Portland Slag Cement combines clinker, slag cement, and gypsum, offering improved workability, reduced heat of hydration, and increased long-term strength for your concrete projects.

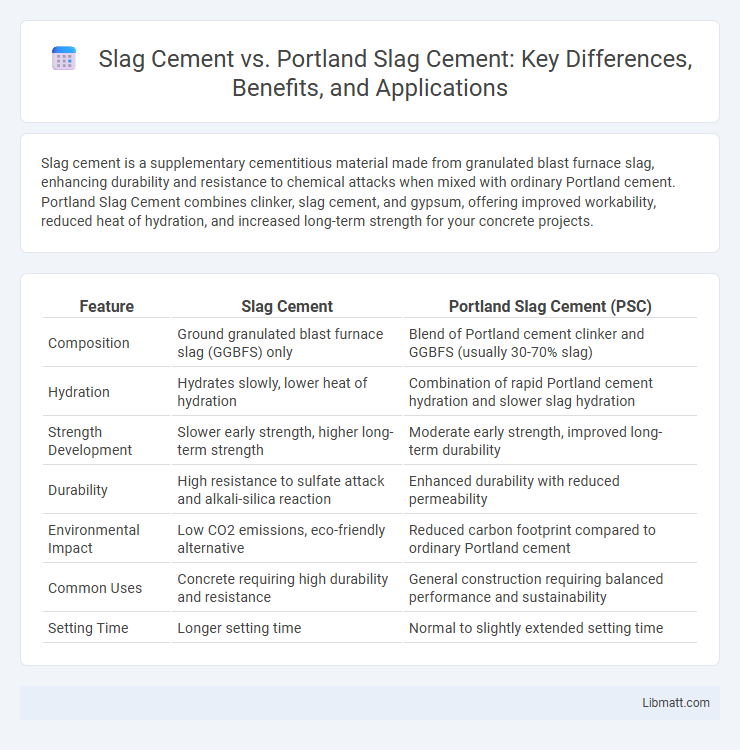

Table of Comparison

| Feature | Slag Cement | Portland Slag Cement (PSC) |

|---|---|---|

| Composition | Ground granulated blast furnace slag (GGBFS) only | Blend of Portland cement clinker and GGBFS (usually 30-70% slag) |

| Hydration | Hydrates slowly, lower heat of hydration | Combination of rapid Portland cement hydration and slower slag hydration |

| Strength Development | Slower early strength, higher long-term strength | Moderate early strength, improved long-term durability |

| Durability | High resistance to sulfate attack and alkali-silica reaction | Enhanced durability with reduced permeability |

| Environmental Impact | Low CO2 emissions, eco-friendly alternative | Reduced carbon footprint compared to ordinary Portland cement |

| Common Uses | Concrete requiring high durability and resistance | General construction requiring balanced performance and sustainability |

| Setting Time | Longer setting time | Normal to slightly extended setting time |

Introduction to Slag Cement and Portland Slag Cement

Slag cement is a supplementary cementitious material produced by granulating and rapidly cooling molten iron blast furnace slag, which enhances concrete durability and reduces permeability. Portland slag cement combines ordinary Portland cement clinker with a specified proportion of granulated blast furnace slag, offering improved sulfate resistance and reduced heat of hydration compared to standard Portland cement. Both materials contribute to sustainable construction by recycling industrial by-products and lowering carbon emissions associated with cement production.

What is Slag Cement?

Slag cement is a byproduct of blast furnace iron production, consisting mainly of granulated blast furnace slag that is ground into a fine powder and used as a supplementary cementitious material. It improves concrete durability, reduces permeability, and enhances resistance to sulfate attack and alkali-silica reaction compared to traditional Portland cement. Your choice of slag cement can significantly increase sustainability in construction by lowering carbon emissions associated with cement production.

What is Portland Slag Cement?

Portland Slag Cement (PSC) is a blended cement composed of ordinary Portland cement and granulated blast furnace slag, typically mixed in proportions ranging from 30% to 70%. This combination enhances durability, resistance to sulfate attack, and reduces heat of hydration compared to conventional Portland cement. PSC is widely used in construction projects requiring improved long-term strength and environmental sustainability.

Composition Differences

Slag cement is primarily composed of ground granulated blast furnace slag (GGBFS), a byproduct of iron production, while Portland slag cement combines ordinary Portland cement clinker with a specified amount of GGBFS. The proportion of slag in Portland slag cement typically ranges from 25% to 70%, altering its chemical and physical properties compared to pure slag cement. Understanding these composition differences helps you select the right material for improved durability and sustainability in construction projects.

Manufacturing Processes

Slag Cement is produced by grinding granulated blast furnace slag, a byproduct of iron production, into a fine powder. Portland Slag Cement (PSC) combines Ordinary Portland Cement (OPC) clinker with a specific percentage of slag, typically 30-70%, offering enhanced durability and sustainability. The integration of slag in PSC manufacturing reduces carbon emissions and improves resistance to chemical attacks compared to traditional OPC.

Key Performance Characteristics

Slag Cement and Portland Slag Cement both enhance concrete durability and reduce permeability but differ in composition and performance. Slag Cement primarily consists of ground granulated blast-furnace slag, offering superior resistance to sulfate attack and improved long-term strength. Portland Slag Cement combines Portland cement clinker with slag, balancing early strength development with enhanced durability and reduced heat of hydration.

Applications in Construction

Slag Cement and Portland Slag Cement are widely used in construction for their durability and resistance to sulfate attack. Slag Cement is commonly incorporated in concrete mixes for infrastructure projects such as bridges and highways to enhance strength and reduce permeability. Portland Slag Cement combines Portland cement with granulated blast furnace slag, making it ideal for applications requiring improved long-term strength and environmental sustainability, including massive concrete structures and marine constructions.

Environmental Impact Comparison

Slag cement significantly reduces carbon emissions by utilizing by-products from steel production, lowering the environmental footprint compared to traditional Portland cement, which relies heavily on limestone calcination. Portland slag cement combines Portland cement clinker with granulated blast furnace slag, enhancing durability and reducing greenhouse gas emissions by slowing concrete hydration and reducing energy consumption. Your sustainable construction choices can benefit from slag cement's ability to recycle industrial waste and decrease overall CO2 output.

Cost and Availability Differences

Slag Cement is often more cost-effective due to its production from granulated blast furnace slag, a byproduct of steel manufacturing, making it widely available in regions with steel plants. Portland Slag Cement, which blends ordinary Portland Cement with slag, generally exhibits slightly higher costs due to additional processing and transportation requirements. Your choice between the two may depend on local supplier availability and project budget constraints, as supply chain factors greatly influence pricing and accessibility.

Choosing the Right Cement for Your Project

Selecting the ideal cement depends on your project requirements, with Slag Cement offering enhanced durability and resistance to sulfate attacks, making it suitable for marine or sewage environments. Portland Slag Cement combines the benefits of OPC and Slag Cement, providing improved strength and reduced permeability, ideal for concrete structures and repair works. Understanding project conditions such as exposure, strength needs, and environmental impact guides the choice between Slag Cement and Portland Slag Cement for optimal performance.

Slag Cement vs Portland Slag Cement Infographic

libmatt.com

libmatt.com