Alkali-resistant cement is designed to prevent alkali-silica reactions in concrete exposed to high-alkali environments, ensuring durability in aggressive conditions. Sulphate-resistant cement protects your structures from sulphate attack by reducing permeability and enhancing resistance to sulphate ions, making it ideal for foundations and sewage systems.

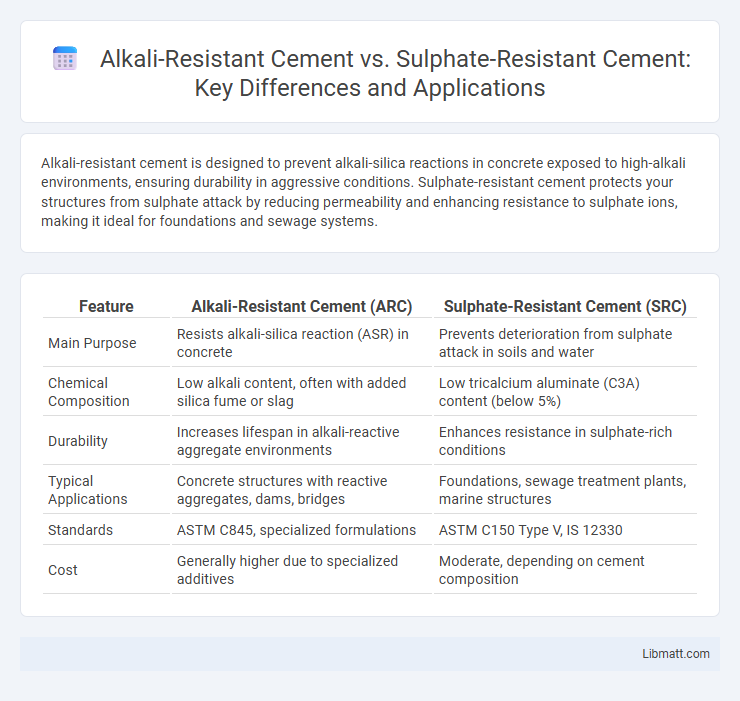

Table of Comparison

| Feature | Alkali-Resistant Cement (ARC) | Sulphate-Resistant Cement (SRC) |

|---|---|---|

| Main Purpose | Resists alkali-silica reaction (ASR) in concrete | Prevents deterioration from sulphate attack in soils and water |

| Chemical Composition | Low alkali content, often with added silica fume or slag | Low tricalcium aluminate (C3A) content (below 5%) |

| Durability | Increases lifespan in alkali-reactive aggregate environments | Enhances resistance in sulphate-rich conditions |

| Typical Applications | Concrete structures with reactive aggregates, dams, bridges | Foundations, sewage treatment plants, marine structures |

| Standards | ASTM C845, specialized formulations | ASTM C150 Type V, IS 12330 |

| Cost | Generally higher due to specialized additives | Moderate, depending on cement composition |

Introduction to Alkali-Resistant and Sulphate-Resistant Cement

Alkali-resistant cement contains low alkali content to prevent alkali-silica reaction in concrete, making it ideal for structures exposed to high alkali environments. Sulphate-resistant cement is formulated with reduced tricalcium aluminate (C3A) to resist sulfate attacks from soil or water, ensuring durability in sulfate-rich conditions. Both cements are specialized for enhancing concrete longevity in chemically aggressive environments.

Composition and Key Ingredients

Alkali-resistant cement contains low alkali content with special compounds like zirconium oxide to prevent alkali-silica reaction, enhancing durability in high-alkali environments. Sulphate-resistant cement features a low tricalcium aluminate (C3A) content, typically below 5%, minimizing its reaction with sulphates to reduce expansion and deterioration. Both cements are formulated to withstand specific chemical attacks, with zirconium oxide critical for alkali resistance and reduced C3A vital for sulphate resistance.

Chemical Mechanisms of Resistance

Alkali-resistant cement resists chemical attacks primarily through reduced alkali content and the inclusion of supplementary cementitious materials like silica fume, which minimize alkali-silica reaction (ASR) by limiting reactive silica dissolution and gel formation. Sulphate-resistant cement combats sulphate attack via lower tricalcium aluminate (C3A) content, preventing the formation of expansive ettringite and thaumasite phases that cause cracking and deterioration in concrete exposed to sulphate-rich environments. Both cements rely on tailored chemical compositions to mitigate specific deleterious reactions, enhancing the durability of concrete in aggressive chemical conditions.

Manufacturing Processes

Alkali-resistant cement is manufactured by incorporating low alkali content clinker and specialized additives such as zirconium compounds to enhance resistance to alkaline environments typically found in glass fiber reinforced concrete. Sulphate-resistant cement production involves selecting raw materials low in tricalcium aluminate (C3A) to minimize reactions with sulfates, achieved through adjusting kiln temperatures and raw mix composition during clinker formation. Both cements require precise control of kiln firing and raw material quality to optimize their chemical compositions for enhanced durability in specific aggressive environments.

Applications in Construction

Alkali-resistant cement is primarily used in constructions involving glass fiber-reinforced concrete or environments with high alkali content to prevent chemical degradation. Sulphate-resistant cement is ideal for foundations, marine structures, and sewage treatment plants where exposure to sulphate-rich soils or groundwater is common. Your choice between these cements should depend on the specific environmental conditions and chemical exposures the structure will face.

Performance in Aggressive Environments

Alkali-resistant cement is specifically designed to withstand high alkali environments, making it ideal for structures exposed to concrete alkali silica reactions (ASR), while sulphate-resistant cement excels in resisting sulphate attacks from soils and groundwater rich in sulphates. Your choice depends on the type of aggressive environment: for high sulphate presence, sulphate-resistant cement ensures better durability, whereas alkali-resistant cement prevents degradation in high-alkali conditions. Both types enhance long-term performance, reducing the risk of structural damage in chemically aggressive settings.

Durability and Longevity Comparisons

Alkali-resistant cement offers superior durability in environments with high alkali content, preventing chemical attacks that can compromise structural integrity over time. Sulphate-resistant cement excels in resisting sulphate-induced deterioration, making it ideal for foundations and marine structures exposed to aggressive sulphate-rich soils or water. Choosing the right cement enhances your project's longevity by addressing specific environmental challenges effectively.

Cost Implications and Availability

Alkali-resistant cement generally incurs higher production costs due to specialized raw materials like zirconium compounds, making it less widely available and pricier compared to sulphate-resistant cement. Sulphate-resistant cement, often produced with lower C3A content, is more commonly accessible and usually offers a more economical option for projects requiring protection against sulphate attack. The cost difference and availability can significantly impact project budgets and timelines, especially in regions where specific raw materials are scarce or transportation adds to expenses.

Environmental Considerations

Alkali-resistant cement reduces environmental impact by minimizing the use of costly and energy-intensive components such as low-alkali clinker, promoting sustainability in concrete production. Sulphate-resistant cement, formulated to withstand aggressive sulfate environments, often requires higher proportions of clinker and supplementary cementitious materials that influence carbon emissions and resource consumption. Selecting alkali-resistant cement can lead to lower embodied energy and greenhouse gas emissions in infrastructure exposed to alkali silicate reactions, whereas sulphate-resistant cement is pivotal in protecting structures exposed to sulfate-rich soils and waters, balancing durability with environmental footprint.

Selection Criteria for Specific Projects

Alkali-resistant cement is ideal for projects involving high-alkali environments such as concrete structures exposed to reactive silica or alkali-silica reaction (ASR) risks, ensuring durability and preventing chemical degradation. Sulphate-resistant cement should be selected for construction in sulphate-rich soils or groundwater, such as sewage treatment plants or marine structures, to prevent sulphate attack and resultant expansion or disintegration. Your project's environmental conditions, including pH levels and exposure to aggressive agents, are critical in determining the appropriate type of specialized cement for long-term performance.

Alkali-resistant cement vs Sulphate-resistant cement Infographic

libmatt.com

libmatt.com