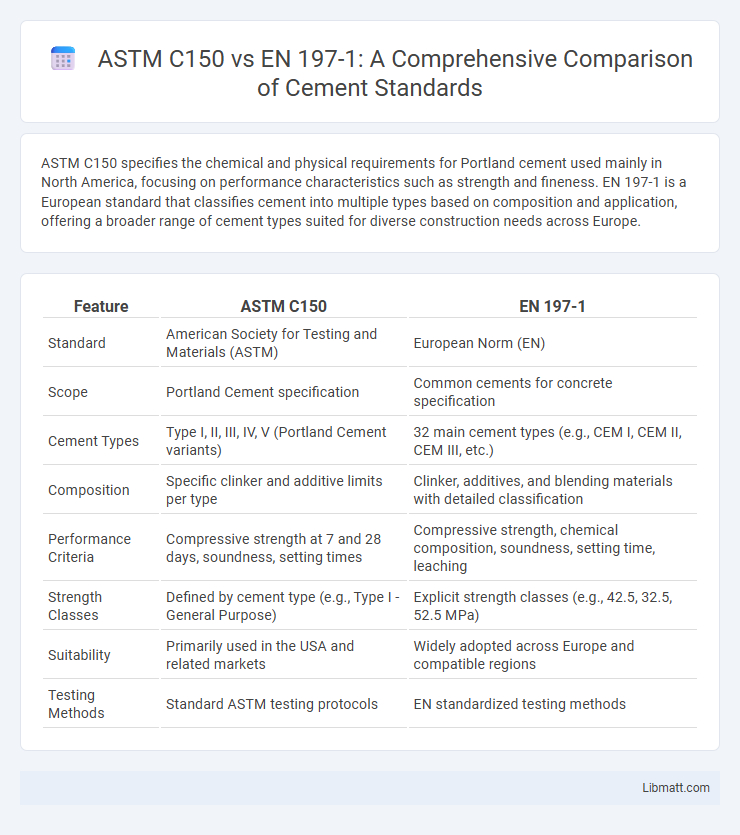

ASTM C150 specifies the chemical and physical requirements for Portland cement used mainly in North America, focusing on performance characteristics such as strength and fineness. EN 197-1 is a European standard that classifies cement into multiple types based on composition and application, offering a broader range of cement types suited for diverse construction needs across Europe.

Table of Comparison

| Feature | ASTM C150 | EN 197-1 |

|---|---|---|

| Standard | American Society for Testing and Materials (ASTM) | European Norm (EN) |

| Scope | Portland Cement specification | Common cements for concrete specification |

| Cement Types | Type I, II, III, IV, V (Portland Cement variants) | 32 main cement types (e.g., CEM I, CEM II, CEM III, etc.) |

| Composition | Specific clinker and additive limits per type | Clinker, additives, and blending materials with detailed classification |

| Performance Criteria | Compressive strength at 7 and 28 days, soundness, setting times | Compressive strength, chemical composition, soundness, setting time, leaching |

| Strength Classes | Defined by cement type (e.g., Type I - General Purpose) | Explicit strength classes (e.g., 42.5, 32.5, 52.5 MPa) |

| Suitability | Primarily used in the USA and related markets | Widely adopted across Europe and compatible regions |

| Testing Methods | Standard ASTM testing protocols | EN standardized testing methods |

Introduction to ASTM C150 and EN 197-1

ASTM C150 specifies the chemical and physical requirements for Portland cement used primarily in the United States, emphasizing performance criteria for various cement types such as Type I through Type V. EN 197-1 is a European standard that classifies cement into different types based on their composition and intended use, including common types like CEM I and CEM II with detailed specifications on strength and durability. Your choice between ASTM C150 and EN 197-1 depends on regional compliance requirements and the specific properties needed for your construction project.

Overview of Cement Standards

ASTM C150 and EN 197-1 are widely recognized cement standards that define specifications for different types of Portland cement, ensuring consistency in quality and performance. ASTM C150, primarily used in the United States, classifies cement into several types such as Type I, II, and III, based on chemical composition and intended use. EN 197-1, the European standard, categorizes cement into clinker types combined with various additives, optimizing properties for diverse construction applications across Europe.

Key Differences in Cement Classification

ASTM C150 classifies portland cement into several types (I through V) based on properties such as sulfate resistance and heat of hydration, while EN 197-1 categorizes cement into 27 types of common cements primarily by composition, including clinker and additional constituents like fly ash or slag. ASTM focuses more on performance requirements and setting characteristics, whereas EN 197-1 emphasizes precise compositional ranges and chemical limits for each cement type. Your choice between the two standards impacts the classification criteria, influencing cement selection for specific environments and structural demands.

Chemical Composition Requirements

ASTM C150 and EN 197-1 specify different chemical composition requirements for cement. ASTM C150 governs the chemical limits for Portland cement, emphasizing oxides such as CaO, SiO2, Al2O3, Fe2O3, and SO3 within defined percentage ranges to ensure consistent performance. EN 197-1 covers multiple cement types, setting broader chemical limits including alkalis (Na2O, K2O) and chloride content to accommodate varied clinker compositions and added materials like slag or fly ash.

Physical Properties and Testing Methods

ASTM C150 specifies physical properties and testing methods for Portland cement, emphasizing compressive strength measured at 3, 7, and 28 days using standardized mortar prisms under controlled curing conditions. EN 197-1 covers a broader range of cement types with detailed requirements for physical properties such as setting time, fineness (by Blaine air permeability), and soundness (via Le Chatelier method), alongside compressive strength testing at 2, 7, and 28 days. Testing methods in ASTM C150 are primarily aligned with American standards (ASTM C109 for strength, ASTM C191 for setting time), whereas EN 197-1 refers to European standards (EN 196 series) to ensure cement consistency and performance.

Types of Cement Defined by Each Standard

ASTM C150 classifies ordinary Portland cement into five main types: Type I (general use), Type II (moderate sulfate resistance), Type III (high early strength), Type IV (low heat of hydration), and Type V (high sulfate resistance). EN 197-1 defines cement based on 27 different binders, combining Portland cement clinker with various additions, categorized into main groups such as CEM I (100% clinker), CEM II (Portland-composite cement), CEM III (blast furnace cement), CEM IV (pozzolanic cement), and CEM V (composite cement). Understanding your project's exposure conditions helps determine whether ASTM C150's focused classification or EN 197-1's diverse cement types better suit your construction requirements.

Setting Time and Strength Criteria

ASTM C150 defines specific setting time requirements for Portland cement, typically requiring an initial set between 45 minutes to 375 minutes and a final set no more than 600 minutes, ensuring controlled hydration and workability. EN 197-1 categorizes cement types by strength classes such as CEM I 42.5, requiring compressive strengths of 42.5 MPa at 28 days, while setting times vary depending on clinker composition but generally align with practical construction standards. Strength criteria in ASTM C150 specify minimum compressive strength at 7 and 28 days, whereas EN 197-1 includes detailed strength classes and chemical limits for diversified cement blends, optimizing performance and durability.

Marking and Certification Procedures

ASTM C150 requires cement manufacturers to provide markings that identify the cement type, manufacturing location, and strength class, with certification based on testing protocols specified by ASTM International to ensure compliance with performance criteria. EN 197-1 mandates that cement bags display key information such as the cement strength class, clinker content, and the standard number, with conformity certification provided through factory production control and external notified body verification in line with EU regulations. Both standards emphasize traceability and quality assurance through detailed labeling and rigorous certification to assure end-user confidence in cement performance.

Global Applications and Market Preferences

ASTM C150, widely recognized in North America, specifies Portland cement types primarily suited for concrete construction, aligning with regional standards and environmental conditions. EN 197-1, prevalent in Europe and many international markets, offers a broader classification of cement types, including blended cements, supporting sustainability and diverse construction needs. Market preferences lean towards ASTM C150 where traditional Portland cement dominates, while EN 197-1 gains traction in regions prioritizing eco-friendly materials and versatile cement formulations.

Choosing the Right Standard for Your Project

Selecting between ASTM C150 and EN 197-1 hinges on project specifications, geographic location, and desired cement properties. ASTM C150 covers portland cement types primarily used in the United States, emphasizing strict chemical composition and physical requirements. EN 197-1 standardizes a wider range of cement types across Europe, incorporating blended cements that improve sustainability and performance in diverse construction applications.

ASTM C150 vs EN 197-1 Infographic

libmatt.com

libmatt.com