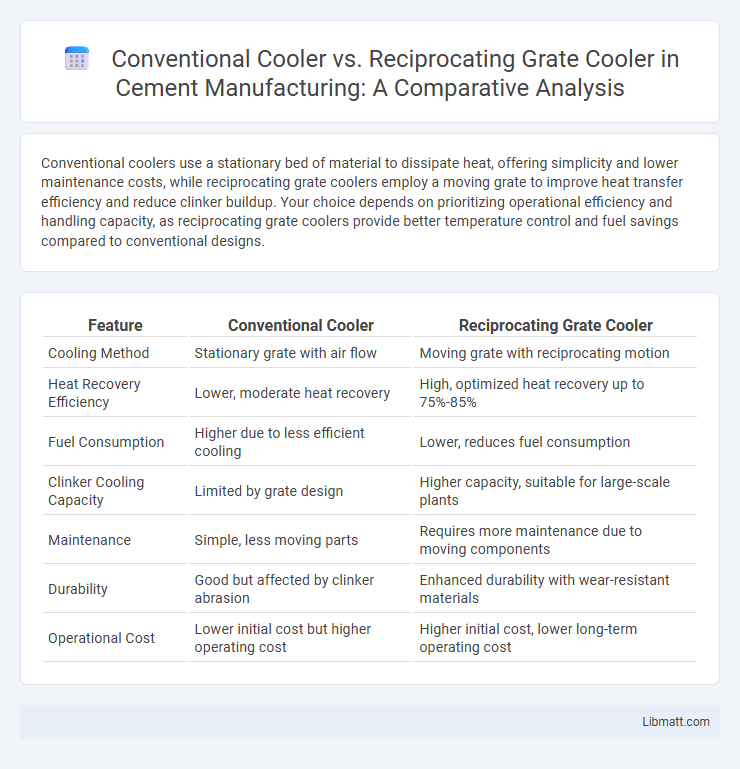

Conventional coolers use a stationary bed of material to dissipate heat, offering simplicity and lower maintenance costs, while reciprocating grate coolers employ a moving grate to improve heat transfer efficiency and reduce clinker buildup. Your choice depends on prioritizing operational efficiency and handling capacity, as reciprocating grate coolers provide better temperature control and fuel savings compared to conventional designs.

Table of Comparison

| Feature | Conventional Cooler | Reciprocating Grate Cooler |

|---|---|---|

| Cooling Method | Stationary grate with air flow | Moving grate with reciprocating motion |

| Heat Recovery Efficiency | Lower, moderate heat recovery | High, optimized heat recovery up to 75%-85% |

| Fuel Consumption | Higher due to less efficient cooling | Lower, reduces fuel consumption |

| Clinker Cooling Capacity | Limited by grate design | Higher capacity, suitable for large-scale plants |

| Maintenance | Simple, less moving parts | Requires more maintenance due to moving components |

| Durability | Good but affected by clinker abrasion | Enhanced durability with wear-resistant materials |

| Operational Cost | Lower initial cost but higher operating cost | Higher initial cost, lower long-term operating cost |

Introduction to Grate Cooler Technologies

Grate cooler technologies play a crucial role in cement production by efficiently cooling clinker as it exits the kiln, impacting overall energy consumption and process stability. Conventional coolers utilize a fixed grate with a steady airflow to dissipate heat, whereas reciprocating grate coolers employ a moving grate system that enhances heat transfer and clinker cooling rates. Reciprocating grate coolers improve thermal efficiency and clinker quality by optimizing airflow distribution and reducing thermal shocks compared to conventional designs.

Overview of Conventional Coolers

Conventional coolers primarily use static grate systems to facilitate the cooling of hot materials, relying on natural convection and conduction to dissipate heat. These coolers are characterized by a simpler design with fewer moving parts, leading to easier maintenance but less efficient heat exchange compared to reciprocating grate coolers. The static nature of their grate limits airflow control, often resulting in uneven cooling and higher energy consumption in industrial applications such as cement manufacturing.

Understanding Reciprocating Grate Coolers

Reciprocating grate coolers use a moving grate system to efficiently cool hot materials by allowing even air circulation and reducing material clumping. Unlike conventional coolers that rely on static beds, reciprocating grate coolers enhance cooling capacity and improve heat recovery in industrial processes. Your choice of a reciprocating grate cooler can lead to better temperature control and increased operational efficiency.

Key Design Differences

Conventional coolers use a fixed grate and rely on downward airflow to cool hot materials, while reciprocating grate coolers feature a moving grate system that efficiently moves and aerates the material for enhanced heat exchange. The reciprocating design improves cooling uniformity and reduces clinker formation by continuously agitating the material bed. Understanding these key design differences helps optimize your industrial cooling process for better thermal efficiency and operational reliability.

Heat Recovery Efficiency Comparison

Reciprocating Grate Coolers offer significantly higher heat recovery efficiency compared to Conventional Coolers due to their enhanced air distribution and extended cooling surface area, maximizing the extraction of heat from hot materials. Your energy savings increase because these coolers convert more thermal energy into usable heat, improving overall process efficiency. By optimizing heat recovery, Reciprocating Grate Coolers reduce fuel consumption and lower operating costs in industrial applications.

Maintenance and Operational Costs

Conventional coolers demand higher maintenance due to frequent wear of moving parts and complex components, leading to increased operational costs over time. Reciprocating grate coolers offer lower maintenance needs with robust design minimizing downtime, resulting in more cost-efficient long-term operation. Your choice significantly impacts overall expenses, with reciprocating grate coolers typically providing superior cost savings in maintenance and operational efficiency.

Performance in Large-Scale Applications

The Reciprocating Grate Cooler outperforms conventional coolers in large-scale applications by providing higher thermal efficiency and improved material handling capacity, leading to better heat recovery and energy savings. Its design facilitates uniform cooling and reduced clinker breakage, which enhances operational reliability and extends equipment lifespan. Conventional coolers often struggle with scaling challenges and uneven cooling, limiting their effectiveness in high-capacity cement production environments.

Impact on Clinker Quality

Conventional coolers often result in uneven cooling rates, leading to temperature gradients that can negatively impact clinker quality by increasing the risk of undesirable mineral formations and reduced strength. Reciprocating grate coolers provide uniform cooling, promoting consistent clinker granule structure and enhancing overall durability and reactivity. Choosing the right cooler directly affects your clinker's physical properties, optimizing performance for cement production.

Energy Consumption Analysis

Reciprocating grate coolers typically exhibit lower energy consumption compared to conventional coolers due to enhanced airflow distribution and optimized heat transfer efficiency. Studies indicate that reciprocating grate coolers reduce fuel usage by up to 15-20% in cement production processes, leading to significant operational cost savings. Their design minimizes temperature fluctuations and promotes uniform cooling, which improves overall thermal efficiency and reduces the need for auxiliary cooling systems.

Conclusion: Choosing the Right Cooler

Selecting the appropriate cooler depends on factors like operational efficiency, maintenance costs, and cooling capacity. Reciprocating grate coolers offer superior heat recovery and reduced clinker cooler exchanger deterioration compared to conventional coolers, making them ideal for high-capacity cement plants. Conventional coolers, while simpler and less expensive initially, may lead to higher energy consumption and increased wear over time.

Conventional Cooler vs Reciprocating Grate Cooler Infographic

libmatt.com

libmatt.com