Premix process involves mixing syrup, water, and carbonation before dispensing, resulting in a ready-to-serve beverage, while postmix process combines syrup and carbonated water at the point of dispensing, allowing for customized carbonation levels. Your choice depends on factors like storage space, beverage volume, and desired freshness, with premix offering convenience and postmix providing flexibility.

Table of Comparison

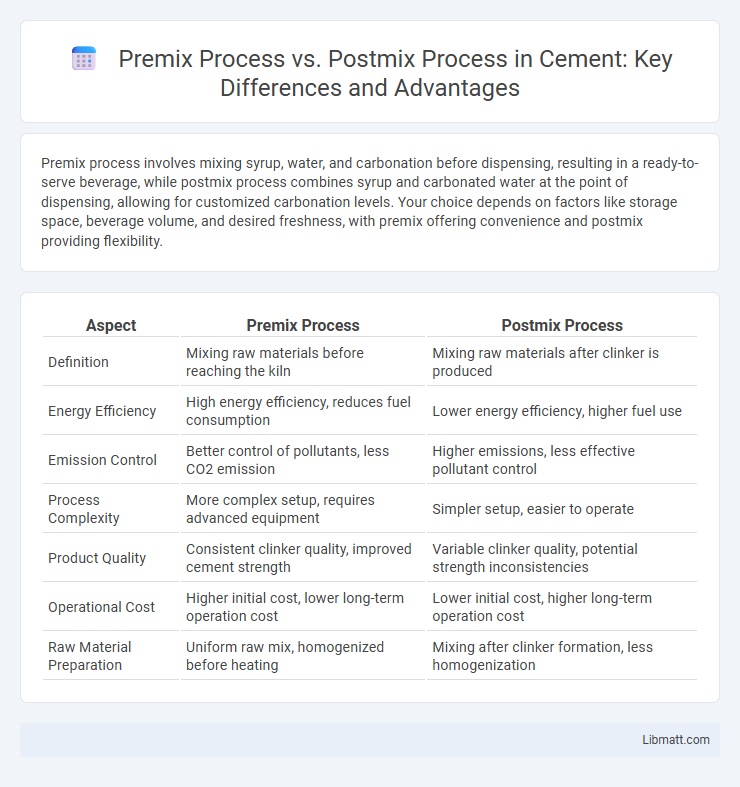

| Aspect | Premix Process | Postmix Process |

|---|---|---|

| Definition | Mixing raw materials before reaching the kiln | Mixing raw materials after clinker is produced |

| Energy Efficiency | High energy efficiency, reduces fuel consumption | Lower energy efficiency, higher fuel use |

| Emission Control | Better control of pollutants, less CO2 emission | Higher emissions, less effective pollutant control |

| Process Complexity | More complex setup, requires advanced equipment | Simpler setup, easier to operate |

| Product Quality | Consistent clinker quality, improved cement strength | Variable clinker quality, potential strength inconsistencies |

| Operational Cost | Higher initial cost, lower long-term operation cost | Lower initial cost, higher long-term operation cost |

| Raw Material Preparation | Uniform raw mix, homogenized before heating | Mixing after clinker formation, less homogenization |

Introduction to Mix Processes in Manufacturing

Premix and postmix processes are critical methods in manufacturing for blending ingredients either before or after the main production stage. The premix process involves combining all raw materials into a uniform mixture prior to processing, ensuring consistent quality and reducing variability in the final product. Your choice between premix and postmix depends on factors like production scale, ingredient stability, and desired product characteristics.

What is the Premix Process?

The Premix Process involves mixing the flavor syrup and carbonated water before dispensing, ensuring consistent taste and carbonation levels in every serving. This method is commonly used in bottling plants and automatic vending machines where the beverage is pre-blended. Premix systems offer precise control over syrup-to-water ratios, improving product uniformity and reducing syrup waste.

What is the Postmix Process?

The Postmix process involves mixing syrup and carbonated water at the point of sale, producing fresh soda on demand. This method typically uses a soda fountain machine, allowing for customizable carbonation levels and efficient beverage dispensing. Your choice of postmix systems can reduce storage needs and maintain consistent drink quality.

Key Differences Between Premix and Postmix

Premix and postmix processes differ primarily in the stage at which syrup and water are combined; premix blends them before carbonation, while postmix mixes syrup with carbonated water at the point of dispensing. Premix systems use pre-carbonated syrup, making them ideal for smaller volume operations with limited space, whereas postmix systems require separate syrup and carbonator units, suiting high-volume environments due to cost efficiency and freshness. Your choice depends on factors like beverage volume, space availability, and maintenance preferences, as postmix offers greater flexibility with flavors and carbonation levels.

Advantages of the Premix Process

The Premix Process offers precise and consistent carbonation levels by mixing syrup and carbonated water before dispensing, enhancing product quality and taste uniformity. It simplifies equipment maintenance due to fewer components exposed to syrup, reducing cleaning frequency and downtime. Energy efficiency is improved as the system controls carbonation ratio centrally, minimizing gas waste compared to postmix alternatives.

Benefits of the Postmix Process

The Postmix Process offers significant cost savings by allowing you to store syrup concentrate and mix it with carbonated water on demand, reducing transportation and storage expenses. This method ensures fresher, better-tasting beverages since the syrup is mixed just before serving, enhancing product quality and customer satisfaction. Postmix systems also provide greater flexibility in flavor options and portion control, optimizing beverage dispensing efficiency for businesses.

Industry Applications: Premix vs. Postmix

Premix process is widely used in industries requiring precise flavor consistency and convenient packaging, such as beverage manufacturing and dairy product production, where the syrup is pre-blended with water before distribution. Postmix process finds extensive application in fast-food chains, vending machines, and fountain drink dispensers, allowing on-site carbonated water mixing to optimize freshness and reduce transportation costs. Your choice between premix and postmix depends on factors like volume, equipment availability, and desired control over the carbonation and flavoring stages in the industry.

Quality Control in Premix and Postmix Processes

Quality control in premix processes ensures that flavorings and sweeteners are uniformly blended with the base syrup before packaging, resulting in consistent taste and quality across all servings. Postmix quality control focuses on the precision of carbonation, temperature, and syrup-to-water ratios at the point of dispensing, critical for maintaining freshness and flavor integrity. Your choice between premix and postmix impacts how quality parameters are monitored, influencing product consistency and customer satisfaction.

Cost Implications: Premix vs. Postmix

Premix systems often involve higher initial costs due to pre-mixed beverage ingredients and storage requirements but reduce operational expenses with simpler dispensing and less frequent maintenance. Postmix systems minimize upfront investment by mixing syrup and carbonated water on demand, leading to lower inventory costs and greater flexibility but may incur higher labor and equipment upkeep expenses. Choosing between premix and postmix impacts your overall cost structure based on beverage volume, storage capacity, and maintenance capabilities.

Choosing the Right Mixing Process for Your Needs

Premix process involves combining syrup and carbonated water before dispensing, ensuring consistent taste and simplified maintenance, ideal for settings with high beverage volume and automated systems. Postmix process mixes syrup and carbonated water at the point of service, offering greater flexibility in flavor adjustments and lower storage space for syrup concentrates, making it suitable for locations with varied drink menus or limited storage. Selecting the right mixing process depends on factors such as beverage volume, space availability, flavor customization needs, and equipment maintenance preferences.

Premix Process vs Postmix Process Infographic

libmatt.com

libmatt.com