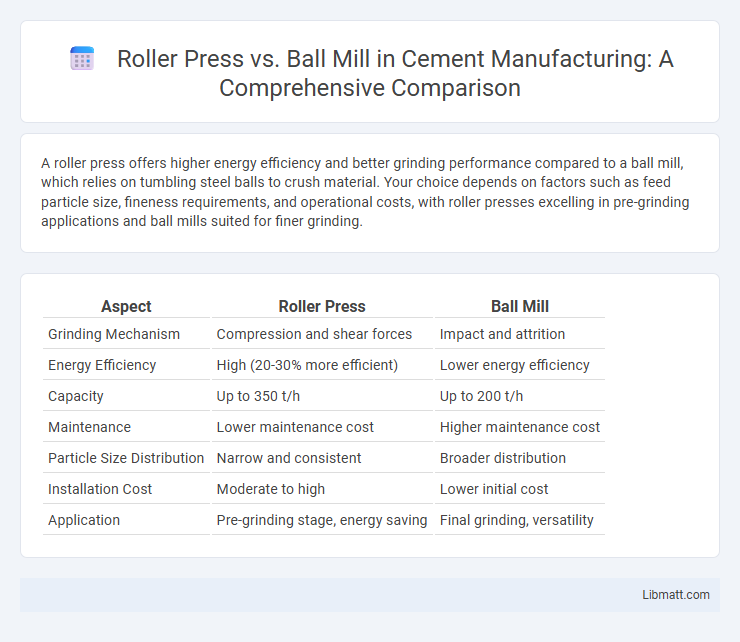

A roller press offers higher energy efficiency and better grinding performance compared to a ball mill, which relies on tumbling steel balls to crush material. Your choice depends on factors such as feed particle size, fineness requirements, and operational costs, with roller presses excelling in pre-grinding applications and ball mills suited for finer grinding.

Table of Comparison

| Aspect | Roller Press | Ball Mill |

|---|---|---|

| Grinding Mechanism | Compression and shear forces | Impact and attrition |

| Energy Efficiency | High (20-30% more efficient) | Lower energy efficiency |

| Capacity | Up to 350 t/h | Up to 200 t/h |

| Maintenance | Lower maintenance cost | Higher maintenance cost |

| Particle Size Distribution | Narrow and consistent | Broader distribution |

| Installation Cost | Moderate to high | Lower initial cost |

| Application | Pre-grinding stage, energy saving | Final grinding, versatility |

Introduction to Roller Press and Ball Mill

Roller presses utilize high-pressure rollers to crush and grind materials, offering energy-efficient size reduction often used in cement grinding circuits. Ball mills consist of rotating cylinders filled with steel balls that grind materials through impact and attrition, commonly applied in mineral processing and cement manufacturing. Both technologies serve distinct roles in optimizing particle size distribution and energy consumption in industrial grinding processes.

Working Principles of Roller Press

A roller press operates by compressing materials between two rotating rollers, generating high pressure that fractures and grinds the particles efficiently. Unlike ball mills that rely on impact and abrasion from rotating balls, roller presses use inter-particle compression, resulting in lower energy consumption and finer grinding. This working principle enhances throughput and reduces operational costs in cement and mineral processing industries.

Working Principles of Ball Mill

The working principle of a ball mill involves rotational motion where steel balls inside the mill grind raw materials through impact and attrition. As the cylinder rotates, the balls are lifted up on the rising side and then cascade down, causing particle size reduction. Understanding this mechanism helps optimize your grinding process compared to the compression method in a roller press.

Energy Efficiency Comparison

Roller presses exhibit higher energy efficiency than ball mills by reducing power consumption by up to 30-40% during fine grinding processes. Their design minimizes energy loss through direct compression and shear forces, whereas ball mills rely on impact and attrition, which consume more energy for the same particle size reduction. Optimizing Your grinding circuit with a roller press can lead to significant energy savings and operational cost reductions in mineral processing.

Grinding Performance and Fineness

Roller Press offers superior grinding performance with higher energy efficiency and more uniform particle size distribution compared to Ball Mills, which often require multiple stages to achieve similar fineness. The Roller Press achieves finer grinding by applying high-pressure compression forces, resulting in enhanced cement strength and reduced grinding time. Your choice between the two should consider that Roller Press typically delivers finer material with lower energy consumption, optimizing overall grinding operations.

Installation and Operational Costs

Roller Press installations typically demand lower initial capital investment and reduced spatial requirements compared to Ball Mills, making them cost-effective for facilities with limited space. Operational costs for Roller Presses are generally lower due to higher energy efficiency and reduced grinding media consumption, whereas Ball Mills incur higher maintenance costs owing to wear and tear of liners and grinding balls. The choice between these grinding systems hinges on a detailed cost-benefit analysis considering installation scope, energy consumption, and long-term maintenance expenses.

Maintenance Requirements and Downtime

Roller press systems require less frequent maintenance compared to ball mills due to fewer moving parts and lower wear rates on rollers and grinding surfaces. Ball mills experience higher downtime caused by the need for regular liner replacements, grinding media consumption, and more complex mechanical maintenance. Optimizing your choice can significantly reduce operational interruptions and maintenance costs, improving overall plant efficiency.

Environmental Impact and Sustainability

Roller presses exhibit lower energy consumption compared to ball mills, significantly reducing carbon emissions in cement and mineral processing industries. The compact design and efficient grinding mechanism of roller presses lead to less dust generation and noise pollution, enhancing environmental sustainability. While ball mills have a longer history of use, roller presses contribute more effectively to resource conservation and decreased ecological footprint in modern manufacturing processes.

Industrial Applications and Case Studies

Roller presses are favored in cement and mineral processing industries for their energy efficiency and compact design, often replacing ball mills in grinding circuits to enhance throughput and reduce power consumption. Ball mills remain widely used across mining and chemical industries due to their versatility in handling various material hardness and size distributions. Your choice between these grinding technologies should consider specific industrial applications and case studies highlighting operational costs, material characteristics, and desired particle size outcomes.

Choosing the Right Grinding Technology

Selecting the right grinding technology depends on factors like material hardness, moisture content, and energy efficiency requirements. Roller presses offer superior energy savings and higher throughput for fine grinding, making them ideal for cement and mineral processing industries. Your choice between roller press and ball mill should consider these performance parameters to optimize grinding efficiency and product quality.

Roller Press vs Ball Mill Infographic

libmatt.com

libmatt.com