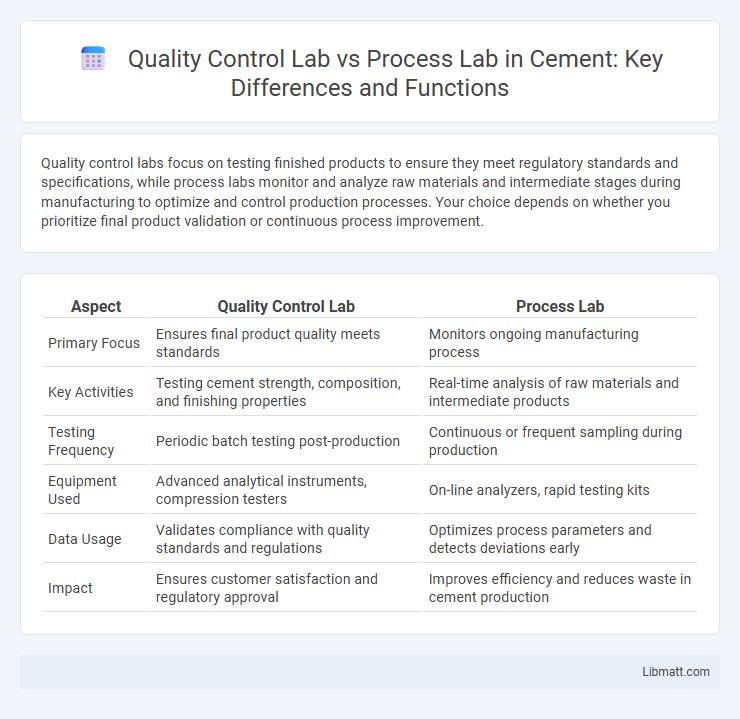

Quality control labs focus on testing finished products to ensure they meet regulatory standards and specifications, while process labs monitor and analyze raw materials and intermediate stages during manufacturing to optimize and control production processes. Your choice depends on whether you prioritize final product validation or continuous process improvement.

Table of Comparison

| Aspect | Quality Control Lab | Process Lab |

|---|---|---|

| Primary Focus | Ensures final product quality meets standards | Monitors ongoing manufacturing process |

| Key Activities | Testing cement strength, composition, and finishing properties | Real-time analysis of raw materials and intermediate products |

| Testing Frequency | Periodic batch testing post-production | Continuous or frequent sampling during production |

| Equipment Used | Advanced analytical instruments, compression testers | On-line analyzers, rapid testing kits |

| Data Usage | Validates compliance with quality standards and regulations | Optimizes process parameters and detects deviations early |

| Impact | Ensures customer satisfaction and regulatory approval | Improves efficiency and reduces waste in cement production |

Introduction to Quality Control Labs and Process Labs

Quality Control Labs ensure product compliance by systematically testing raw materials, in-process samples, and final products against established standards. Process Labs focus on monitoring and optimizing manufacturing parameters to improve efficiency, reduce variability, and maintain consistent product quality. Your organization benefits from integrating both labs to guarantee product reliability and streamline production workflows.

Key Functions of a Quality Control Lab

A Quality Control Lab primarily focuses on ensuring product compliance by performing rigorous testing of raw materials, in-process samples, and finished goods according to predefined specifications and regulatory standards. It plays a critical role in validating product safety, potency, and purity through analytical techniques such as chromatography, spectroscopy, and microbiological assays. The lab's key functions include detecting deviations, preventing release of nonconforming batches, and supporting regulatory audits to maintain overall product quality and integrity.

Main Roles of a Process Lab

Process labs primarily focus on monitoring and optimizing manufacturing operations by analyzing in-process materials to ensure consistency and compliance with production standards. They provide real-time data critical for adjusting parameters during production, enhancing efficiency and minimizing defects. Your involvement with a process lab ensures immediate quality checks that support continuous improvement in product quality before final testing in a quality control lab.

Differences in Testing Methodologies

Quality control labs primarily employ standardized, validated testing methodologies designed to ensure product compliance with regulatory specifications, focusing on accuracy and reproducibility of results. Process labs utilize real-time, rapid testing methods such as in-line spectroscopy or process analytical technology (PAT) to monitor and control manufacturing parameters, enabling immediate adjustments to optimize production efficiency. The key difference lies in quality control labs emphasizing confirmatory testing post-production, while process labs focus on dynamic, continuous monitoring during the manufacturing process.

Sampling Strategies: QC Lab vs Process Lab

Quality Control (QC) labs employ rigorous sampling strategies centered on representativeness and compliance to ensure final product integrity through validated methods and statistical sampling plans. Process labs prioritize real-time, frequent sampling within production stages to monitor critical process parameters, enabling immediate adjustments and continuous quality assurance. Sampling in QC labs aligns with regulatory standards for batch release, while process lab sampling emphasizes operational efficiency and early defect detection.

Equipment and Technologies Used

Quality control labs utilize high-precision analytical instruments such as gas chromatographs, spectrophotometers, and mass spectrometers to ensure product compliance with regulatory standards. Process labs rely on real-time monitoring tools like near-infrared (NIR) analyzers, pH meters, and inline sensors designed to optimize manufacturing efficiency and maintain consistent process parameters. Both labs integrate advanced software platforms for data acquisition and analysis, but quality control labs emphasize testing accuracy while process labs prioritize continuous process improvement.

Regulatory Compliance and Documentation

Quality control labs ensure regulatory compliance by rigorously following standardized testing protocols and maintaining detailed documentation for batch release and audits. Process labs focus on real-time monitoring and adjustments during manufacturing, documenting process parameters to meet regulatory standards for consistent product quality. Your ability to integrate both lab types' documentation supports comprehensive regulatory adherence and traceability throughout production.

Impact on Product Consistency and Safety

Quality control labs ensure product consistency and safety by rigorously testing raw materials, intermediates, and finished products for compliance with established standards, preventing defective batches from reaching consumers. Process labs monitor real-time production parameters and intermediate product quality, enabling immediate adjustments that maintain process stability and prevent deviations. The combined efforts of both labs minimize variability, reduce contamination risks, and enhance overall product reliability in regulated manufacturing environments.

Collaboration Between QC and Process Labs

Collaboration between Quality Control (QC) and Process Labs enhances product consistency by aligning analytical testing with manufacturing processes, ensuring real-time quality monitoring. QC labs provide critical data on compliance and specifications, while Process Labs focus on optimizing parameters and troubleshooting production issues, creating a feedback loop that improves efficiency. Your organization benefits from integrated communication and shared methodologies, driving faster problem resolution and maintaining high-quality standards throughout production.

Choosing the Right Lab for Your Manufacturing Needs

Quality control labs focus on testing finished products to ensure compliance with regulatory standards and specifications, while process labs monitor and analyze raw materials and in-process samples to optimize manufacturing efficiency. Choosing the right lab for your manufacturing needs depends on whether you require final product validation or continuous process improvement. Your decision should align with goals such as regulatory compliance, production consistency, and real-time quality assurance.

Quality control lab vs Process lab Infographic

libmatt.com

libmatt.com