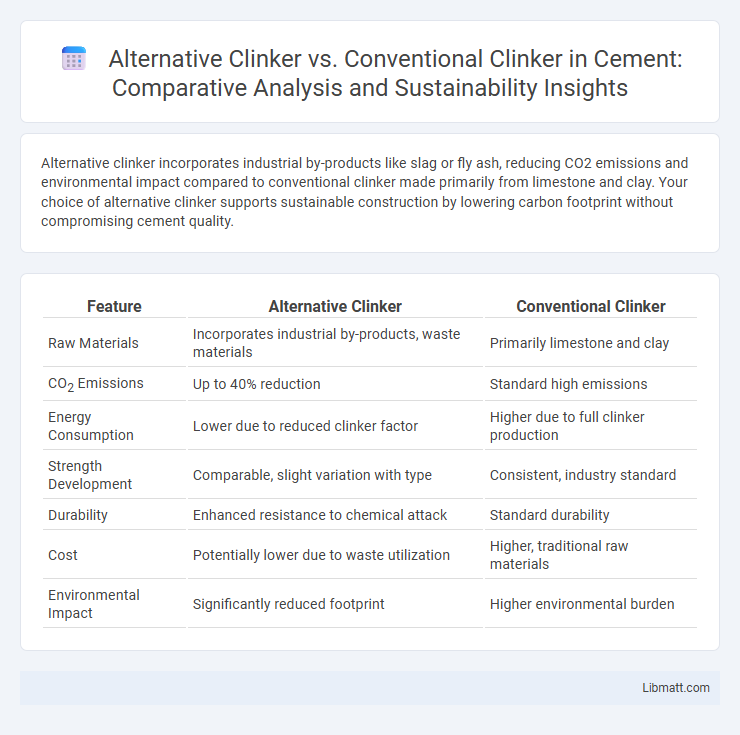

Alternative clinker incorporates industrial by-products like slag or fly ash, reducing CO2 emissions and environmental impact compared to conventional clinker made primarily from limestone and clay. Your choice of alternative clinker supports sustainable construction by lowering carbon footprint without compromising cement quality.

Table of Comparison

| Feature | Alternative Clinker | Conventional Clinker |

|---|---|---|

| Raw Materials | Incorporates industrial by-products, waste materials | Primarily limestone and clay |

| CO2 Emissions | Up to 40% reduction | Standard high emissions |

| Energy Consumption | Lower due to reduced clinker factor | Higher due to full clinker production |

| Strength Development | Comparable, slight variation with type | Consistent, industry standard |

| Durability | Enhanced resistance to chemical attack | Standard durability |

| Cost | Potentially lower due to waste utilization | Higher, traditional raw materials |

| Environmental Impact | Significantly reduced footprint | Higher environmental burden |

Introduction to Clinker: Alternative vs. Conventional

Conventional clinker, produced by heating limestone and other raw materials in a rotary kiln at high temperatures, serves as the primary binder in traditional Portland cement. Alternative clinker, often derived using supplementary cementitious materials such as fly ash, slag, or calcined clays, reduces carbon dioxide emissions and energy consumption during production. These sustainable variations aim to maintain similar mechanical properties and durability while minimizing environmental impact.

Composition and Raw Materials

Alternative clinker incorporates industrial by-products such as fly ash, slag, and silica fume alongside traditional limestone and clay, reducing reliance on virgin raw materials and lowering carbon emissions. Conventional clinker primarily consists of calcium carbonate from limestone, combined with clay and minor additives, resulting in higher calcium silicate phases that deliver standard cement properties. The inclusion of alternative raw materials modifies the chemical composition, impacting mineralogy and hydration behavior, often enhancing sustainability and performance in eco-friendly cement production.

Manufacturing Process Differences

Alternative clinker production incorporates supplementary materials such as industrial by-products and natural pozzolans, reducing the need for high-temperature calcination and lowering CO2 emissions. Conventional clinker manufacturing relies heavily on limestone calcination at temperatures around 1450degC, resulting in significant energy consumption and CO2 release. The alternative process often employs lower kiln temperatures or partial substitution techniques, enhancing sustainability and resource efficiency in cement production.

Environmental Impact Comparison

Alternative clinker significantly reduces CO2 emissions compared to conventional clinker by incorporating industrial by-products like fly ash and slag, which lowers the need for limestone calcination and fuel consumption. Conventional clinker production accounts for approximately 8% of global CO2 emissions, primarily due to the calcination process and fossil fuel combustion. Using alternative clinker not only decreases carbon footprint but also reduces raw material extraction, contributing to more sustainable cement manufacturing and lowering overall environmental impact.

Energy Efficiency and Carbon Emissions

Alternative clinker production significantly reduces energy consumption by utilizing waste materials and lower-temperature processes compared to conventional clinker, which relies heavily on fossil fuels. This shift results in substantially lower carbon emissions, cutting greenhouse gases by up to 30% in many cases. You can enhance your sustainability goals by choosing alternative clinker, which supports energy-efficient manufacturing and a smaller carbon footprint.

Performance in Concrete Applications

Alternative clinker, incorporating materials like slag or fly ash, enhances concrete durability by reducing permeability and improving resistance to chemical attacks compared to conventional clinker. Its lower calcium content and finer particle size contribute to improved workability and long-term strength development in concrete mixtures. Performance tests highlight that alternative clinker concrete exhibits comparable or superior compressive strength and sustainability benefits in structural and infrastructural applications.

Economic Considerations and Cost Analysis

Alternative clinker production reduces energy consumption by utilizing industrial by-products, lowering fuel costs compared to conventional clinker manufacturing. You can benefit from decreased raw material expenses due to partial replacement of traditional limestone and clay with alternative materials such as slag or fly ash. Long-term economic considerations also include lower carbon taxes and potential government incentives promoting eco-friendly cement production.

Regulatory Standards and Compliance

Alternative clinker production must meet stringent regulatory standards such as ASTM C1157 and EN 197-1 to ensure environmental compliance and structural integrity, often requiring extensive testing for emissions and chemical composition. Conventional clinker follows well-established regulations, primarily focusing on limiting SO2, NOx, and CO2 emissions according to EPA and EU directives, ensuring consistent quality and safety. Compliance challenges for alternative clinker include adapting to evolving environmental policies and proving equivalence in performance to gain certification and market acceptance.

Challenges and Future Prospects

Alternative clinker faces challenges such as inconsistent material quality, higher production costs, and the need for specialized technology to ensure performance comparable to conventional clinker. Future prospects include advancements in sustainable raw materials, improved kiln processes, and regulatory support promoting lower carbon emissions in cement production. Your ability to adopt alternative clinker depends on ongoing innovation and industry acceptance to overcome these hurdles and realize environmental benefits.

Conclusion: The Future of Clinker Production

Alternative clinker production offers significant environmental benefits by reducing CO2 emissions and utilizing industrial by-products like fly ash and slag, fostering sustainable construction practices. Conventional clinker remains dominant due to its established manufacturing processes and consistent performance, but increasing regulatory pressures and carbon pricing accelerate the shift toward greener alternatives. Innovations in low-carbon technologies and optimized raw material blends position alternative clinker as the future standard for sustainable cement production.

Alternative Clinker vs Conventional Clinker Infographic

libmatt.com

libmatt.com