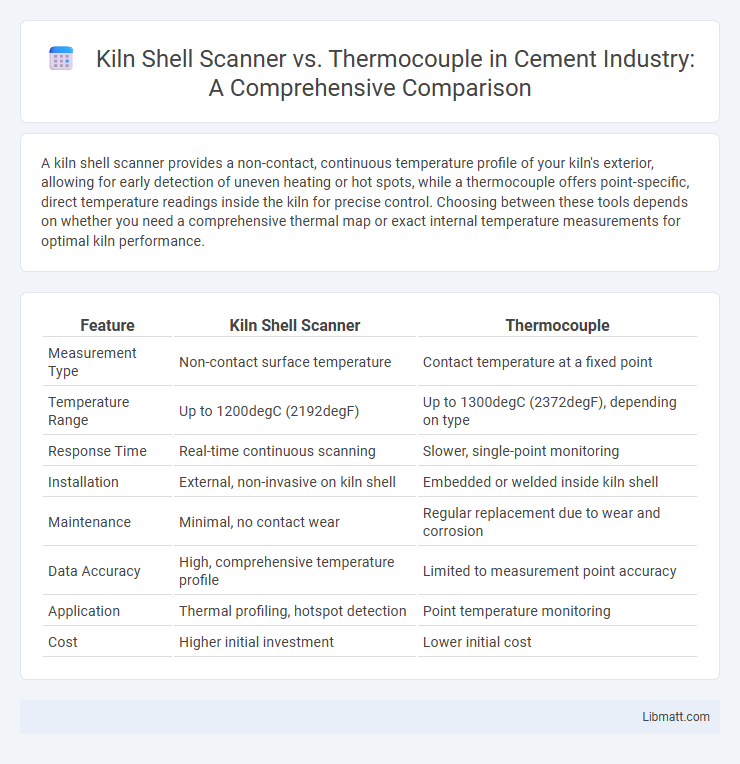

A kiln shell scanner provides a non-contact, continuous temperature profile of your kiln's exterior, allowing for early detection of uneven heating or hot spots, while a thermocouple offers point-specific, direct temperature readings inside the kiln for precise control. Choosing between these tools depends on whether you need a comprehensive thermal map or exact internal temperature measurements for optimal kiln performance.

Table of Comparison

| Feature | Kiln Shell Scanner | Thermocouple |

|---|---|---|

| Measurement Type | Non-contact surface temperature | Contact temperature at a fixed point |

| Temperature Range | Up to 1200degC (2192degF) | Up to 1300degC (2372degF), depending on type |

| Response Time | Real-time continuous scanning | Slower, single-point monitoring |

| Installation | External, non-invasive on kiln shell | Embedded or welded inside kiln shell |

| Maintenance | Minimal, no contact wear | Regular replacement due to wear and corrosion |

| Data Accuracy | High, comprehensive temperature profile | Limited to measurement point accuracy |

| Application | Thermal profiling, hotspot detection | Point temperature monitoring |

| Cost | Higher initial investment | Lower initial cost |

Introduction to Kiln Temperature Monitoring

Kiln temperature monitoring is essential for efficient kiln shell integrity and product quality control, with Kiln Shell Scanners and thermocouples serving key roles. Kiln Shell Scanners provide continuous, non-contact surface temperature measurements along the kiln shell, enabling early detection of hotspots and structural issues. Thermocouples offer direct internal temperature readings but require physical installation inside the kiln, making them suitable for specific process control points rather than comprehensive shell temperature profiling.

Overview of Kiln Shell Scanners

Kiln shell scanners provide non-contact temperature measurement by using infrared sensors to detect heat patterns on the kiln's exterior, enabling precise monitoring of temperature distribution. These devices offer real-time thermal imaging, allowing operators to identify hot or cold spots that could indicate refractory damage or process inefficiencies. Compared to thermocouples, kiln shell scanners reduce maintenance requirements and provide comprehensive surface temperature profiles without direct sensor installation inside the kiln.

Understanding Thermocouples in Kiln Operations

Thermocouples in kiln operations provide precise temperature measurements critical for maintaining optimal firing conditions and product quality. Unlike Kiln Shell Scanners that monitor surface temperatures, thermocouples measure internal kiln temperatures directly within the firing zone, ensuring accurate control of heat distribution. These sensors are vital for process optimization, energy efficiency, and preventing damage caused by overheating or inconsistent temperatures.

Key Differences Between Shell Scanners and Thermocouples

Kiln shell scanners utilize infrared sensors to continuously monitor the temperature profile of the kiln's exterior, providing a real-time thermal map that helps detect hotspots and shell cooling issues. Thermocouples, in contrast, measure temperature at specific points by direct contact, offering precise but localized readings that may miss wider thermal variations. The main difference lies in the shell scanner's ability to deliver comprehensive, non-contact temperature data for predictive maintenance, whereas thermocouples provide targeted, point-specific thermal information used primarily for process control.

Accuracy and Reliability: A Comparative Analysis

Kiln Shell Scanners provide continuous, accurate temperature profiles by using infrared sensors that measure surface heat, ensuring reliable monitoring in harsh kiln environments. Thermocouples offer direct contact temperature measurements with high precision but are susceptible to wear and signal drift over time, impacting long-term reliability. Choosing the appropriate device for your kiln system depends on balancing the need for non-invasive temperature mapping against maintenance and accuracy priorities.

Installation and Maintenance Considerations

Kiln shell scanners offer non-intrusive installation by mounting externally on the kiln shell, reducing downtime and eliminating direct exposure to harsh kiln interior conditions. Thermocouples require insertion into the kiln shell, which may necessitate kiln shutdowns for installation and regular maintenance due to sensor wear and potential drift. The external positioning of kiln shell scanners simplifies maintenance, providing continuous temperature monitoring without physical sensor replacement, whereas thermocouples demand periodic calibration and possible sensor replacement to ensure accuracy.

Real-time Data and Monitoring Capabilities

Kiln shell scanners provide continuous, real-time temperature mapping across the kiln's surface, enabling precise detection of hotspots and uniform heat distribution. Thermocouples offer point-specific temperature readings, which can miss localized temperature anomalies and require multiple sensors for broader coverage. The advanced monitoring capabilities of kiln shell scanners enhance predictive maintenance and process optimization by delivering comprehensive thermal profiles in contrast to the limited real-time data from thermocouples.

Cost Implications and Operational Efficiency

Kiln shell scanners offer higher initial costs compared to traditional thermocouples but provide enhanced operational efficiency by delivering real-time temperature profiles across the kiln shell, reducing downtime and maintenance expenses. Thermocouples, while more affordable upfront, often require frequent replacements and provide limited localized temperature data, potentially leading to less accurate monitoring and higher long-term operational costs. Investing in kiln shell scanners can lead to improved process control and energy savings, offsetting their greater initial expenditure through operational benefits.

Safety and Process Optimization Benefits

Kiln shell scanners enhance safety by providing continuous, non-invasive temperature monitoring, reducing the risk of equipment failure and hazardous conditions caused by overheating. Compared to thermocouples, these scanners offer more accurate and comprehensive thermal profiling, allowing precise process optimization for energy efficiency and consistent product quality. Your facility benefits from early detection of hotspots, minimizing downtime and maintenance costs while improving overall operational safety.

Choosing the Right Solution for Your Kiln

Choosing the right solution for your kiln involves comparing the Kiln Shell Scanner's advanced infrared technology with the proven temperature accuracy of thermocouples. A Kiln Shell Scanner offers non-contact surface temperature measurements, ideal for monitoring kiln shell integrity and reducing maintenance downtime. Thermocouples provide direct, reliable internal kiln temperature data crucial for precise process control and product quality.

Kiln Shell Scanner vs Thermocouple Infographic

libmatt.com

libmatt.com