A preheater heats raw materials before entering the kiln to improve energy efficiency, while a precalciner initiates the calcination process outside the kiln, enhancing production capacity and reducing fuel consumption. Understanding the difference between a preheater and a precalciner helps optimize your cement manufacturing process for better performance and cost savings.

Table of Comparison

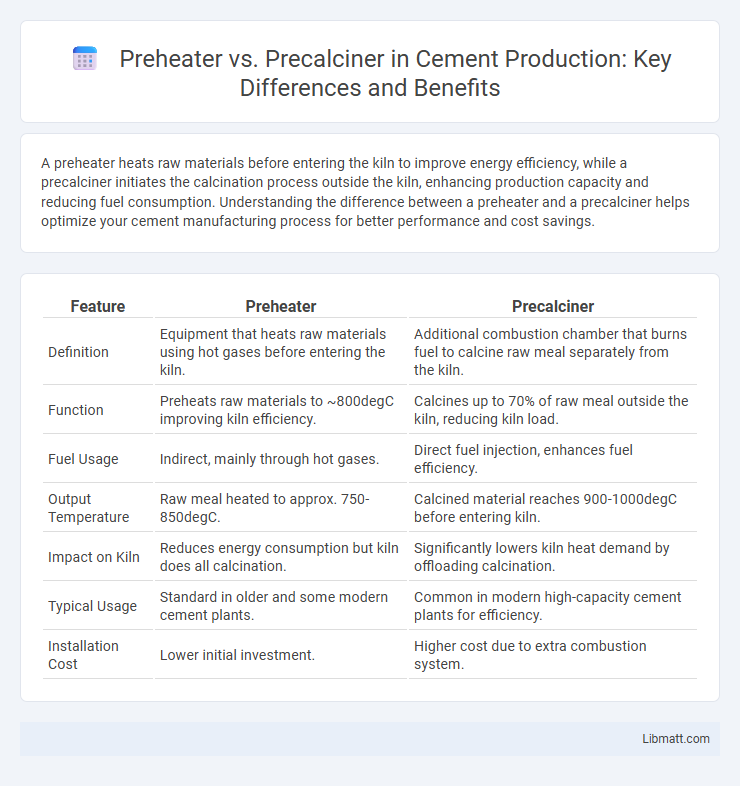

| Feature | Preheater | Precalciner |

|---|---|---|

| Definition | Equipment that heats raw materials using hot gases before entering the kiln. | Additional combustion chamber that burns fuel to calcine raw meal separately from the kiln. |

| Function | Preheats raw materials to ~800degC improving kiln efficiency. | Calcines up to 70% of raw meal outside the kiln, reducing kiln load. |

| Fuel Usage | Indirect, mainly through hot gases. | Direct fuel injection, enhances fuel efficiency. |

| Output Temperature | Raw meal heated to approx. 750-850degC. | Calcined material reaches 900-1000degC before entering kiln. |

| Impact on Kiln | Reduces energy consumption but kiln does all calcination. | Significantly lowers kiln heat demand by offloading calcination. |

| Typical Usage | Standard in older and some modern cement plants. | Common in modern high-capacity cement plants for efficiency. |

| Installation Cost | Lower initial investment. | Higher cost due to extra combustion system. |

Introduction to Preheater and Precalciner Systems

Preheater and precalciner systems are crucial components in modern cement production, optimizing thermal efficiency and fuel consumption. The preheater utilizes multiple cyclone stages to heat raw materials using hot gases from the kiln, while the precalciner combusts additional fuel to pre-calcine materials, significantly enhancing the overall reaction process. Integrating both systems improves clinker quality and reduces energy costs by maximizing heat recovery and accelerating raw meal conversion.

Basic Definitions: What is a Preheater?

A preheater is a critical component in cement manufacturing that heats raw materials using hot gases from the kiln, improving energy efficiency and reducing fuel consumption. It typically consists of cyclones arranged vertically to maximize heat exchange between raw feed and exhaust gases. This process enhances the overall thermal efficiency and supports continuous production by preconditioning materials before entering the kiln.

Understanding the Precalciner: Function and Purpose

The precalciner is a crucial component in cement production, designed to improve thermal efficiency by completing the calcination process before the kiln. It functions by mixing hot gases with raw meal, rapidly converting calcium carbonate to calcium oxide, reducing the kiln's fuel consumption and increasing production capacity. This process allows for higher throughput and better temperature control compared to traditional preheater systems, optimizing overall kiln performance.

Key Differences Between Preheater and Precalciner

Preheaters primarily function to preheat raw materials using exhaust gases, enhancing energy efficiency before entering the kiln, whereas precalciners facilitate the calcination process by injecting fuel directly to enable partial decomposition of limestone outside the kiln. The preheater is generally a tower-like structure with cyclone stages, whereas the precalciner is an additional combustion chamber positioned between the preheater and kiln. Your cement production efficiency improves significantly by understanding these key differences, optimizing fuel consumption and thermal performance.

Process Flow Comparison: Preheater vs Precalciner

The process flow in a Preheater system involves raw materials passing through multiple cyclone stages to recover heat before entering the rotary kiln for clinker formation. In contrast, a Precalciner system introduces fuel and combustion gases independently into the precalciner tower, which allows for further fuel combustion outside the kiln and higher thermal efficiency. Your cement production benefits from the precalciner's enhanced combustion control, leading to increased throughput and reduced energy consumption compared to the preheater alone.

Energy Efficiency: Which System Performs Better?

The precalciner system outperforms the preheater in energy efficiency by enabling more complete fuel combustion before the kiln, reducing fuel consumption by up to 15%. Preheaters rely primarily on heat recovery from kiln exhaust gases, while precalciners inject fuel directly into the calcining zone, increasing thermal utilization and lowering specific energy demand. Industrial data shows precalciner kilns can achieve thermal efficiencies exceeding 80%, compared to 70-75% for preheater-only configurations.

Impact on Clinker Quality and Production

Preheaters improve clinker quality by ensuring uniform raw material heating, leading to better chemical composition consistency and reduced fuel consumption. Precalciners enhance production capacity by increasing the combustion efficiency, allowing earlier and more complete calcination, which accelerates clinker formation and reduces kiln load. Both technologies positively impact clinker quality and production, but precalciners typically offer greater improvements in output rates and energy efficiency.

Environmental Considerations and Emissions

Preheaters reduce emissions by improving fuel efficiency and lowering NOx output through staged combustion, while precalciners further enhance environmental performance by allowing higher fuel substitution rates with alternative fuels, significantly cutting CO2 emissions. Precalciners enable better process control, reducing volatile organic compounds (VOCs) and particulate matter compared to traditional preheaters. Both systems contribute to meeting stringent environmental regulations, but precalciner technology offers superior emissions reduction and sustainable cement production benefits.

Cost Implications: Installation and Operating Costs

Preheater systems generally have lower initial installation costs compared to precalciner systems due to their simpler design and reduced equipment requirements. However, precalciner technology offers improved fuel efficiency and lower operating costs by enabling more complete combustion and better thermal utilization. Evaluating total cost implications involves balancing the upfront investment of precalciner installation against long-term savings in fuel consumption and maintenance expenses.

Choosing the Right System: Factors to Consider

Selecting between a preheater and a precalciner system depends on factors such as fuel efficiency, process stability, and clinker quality requirements. Precalciner systems offer higher thermal efficiency and greater capacity for fuel flexibility, making them ideal for larger plants with stringent emissions standards. Evaluating factors like operational costs, environmental regulations, and plant scale ensures optimal system choice for cement production.

Preheater vs Precalciner Infographic

libmatt.com

libmatt.com