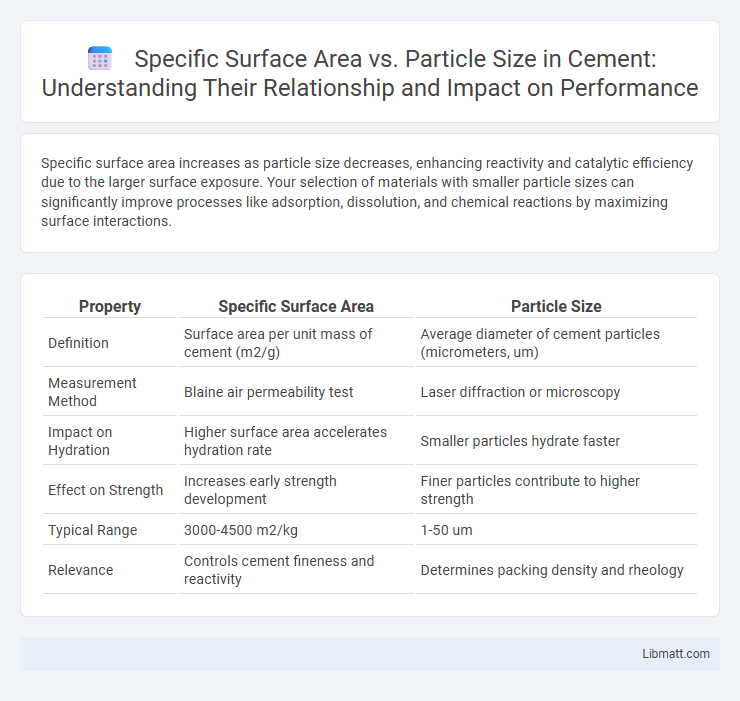

Specific surface area increases as particle size decreases, enhancing reactivity and catalytic efficiency due to the larger surface exposure. Your selection of materials with smaller particle sizes can significantly improve processes like adsorption, dissolution, and chemical reactions by maximizing surface interactions.

Table of Comparison

| Property | Specific Surface Area | Particle Size |

|---|---|---|

| Definition | Surface area per unit mass of cement (m2/g) | Average diameter of cement particles (micrometers, um) |

| Measurement Method | Blaine air permeability test | Laser diffraction or microscopy |

| Impact on Hydration | Higher surface area accelerates hydration rate | Smaller particles hydrate faster |

| Effect on Strength | Increases early strength development | Finer particles contribute to higher strength |

| Typical Range | 3000-4500 m2/kg | 1-50 um |

| Relevance | Controls cement fineness and reactivity | Determines packing density and rheology |

Introduction to Specific Surface Area and Particle Size

Specific surface area measures the total surface area of particles per unit mass, impacting reactions, adsorption, and catalysis efficiency. Particle size directly influences specific surface area, with smaller particles exhibiting a higher surface area-to-volume ratio. Understanding the relationship between specific surface area and particle size helps optimize material performance in your applications.

Definition and Measurement of Specific Surface Area

Specific surface area (SSA) quantifies the total surface area of a material per unit of mass or volume, crucial for characterizing nanoparticles and powders. It is commonly measured using techniques like the BET (Brunauer-Emmett-Teller) method, which analyzes gas adsorption to determine surface area. Understanding how SSA varies with particle size helps optimize Your materials' reactivity, catalytic efficiency, and overall performance.

Understanding Particle Size and Its Determination

Particle size significantly influences the specific surface area, with smaller particles exhibiting a larger surface area per unit mass due to their higher surface-to-volume ratio. Precise determination of particle size involves techniques such as laser diffraction, dynamic light scattering, and microscopy, which provide critical data for optimizing material properties and performance. Understanding your particle size is essential for controlling the specific surface area, directly impacting reactivity, dissolution rate, and overall efficacy in applications.

Relationship Between Specific Surface Area and Particle Size

Specific surface area inversely correlates with particle size, as smaller particles exhibit a higher surface area per unit mass due to increased surface exposure. This relationship is critical in materials science and catalysis, where fine particles enhance reactivity and interaction rates. Quantitatively, reducing particle diameter by half approximately doubles the specific surface area, emphasizing the importance of nanoscale control in optimizing material properties.

Importance in Material Properties and Performance

Specific surface area inversely correlates with particle size, significantly impacting material reactivity, strength, and catalytic efficiency. Smaller particles exhibit higher specific surface areas, enhancing processes such as adsorption, dissolution, and chemical reactions essential for applications in pharmaceuticals, catalysts, and composites. Optimizing particle size to maximize specific surface area directly improves material performance, durability, and function across various industrial and scientific fields.

Influence on Reactivity and Catalytic Efficiency

Specific surface area plays a crucial role in determining reactivity and catalytic efficiency, as a higher surface area provides more active sites for chemical reactions, enhancing catalyst performance. Smaller particle size increases the specific surface area, improving the availability of reactive sites and accelerating reaction rates in various catalytic processes. Understanding this relationship allows you to optimize catalyst design for maximum efficiency in industrial and chemical applications.

Impact on Mechanical and Physical Properties

Specific surface area significantly influences the mechanical strength and physical behavior of materials, as smaller particle sizes increase the surface area, enhancing reactivity and adhesion properties. Higher specific surface area improves material densification and bonding in composites, leading to greater hardness and durability while affecting thermal and electrical conductivity. Your choice of particle size directly impacts the performance and longevity of engineered materials, making precise control essential for optimizing mechanical and physical properties.

Techniques for Controlling Specific Surface Area and Particle Size

Techniques for controlling specific surface area and particle size include methods like milling, spray drying, and controlled precipitation, which directly influence the texture and performance of materials in industries such as pharmaceuticals and catalysts. Precise regulation of these parameters is achieved through process variables like temperature, feed rate, and solvent selection to tailor surface properties and particle distribution. Your ability to optimize these techniques ensures improved material functionality, stability, and reactivity.

Applications in Industry and Research

Specific surface area directly influences particle size, playing a crucial role in industries such as pharmaceuticals, catalysis, and materials science where surface reactions and adsorption efficiency are vital. Smaller particle sizes increase the specific surface area, enhancing drug dissolution rates, catalytic activity, and sensor sensitivity, which researchers exploit to develop advanced materials and improve product performance. Understanding this relationship enables you to optimize formulations and processes for better industrial applications and innovative research outcomes.

Future Trends and Developments in Particle Engineering

Future trends in particle engineering emphasize the precise control of specific surface area to optimize material performance in catalysis, pharmaceuticals, and energy storage. Advances in nanoscale fabrication and machine learning enable tailored particle size distributions that enhance reactivity and stability. Your ability to manipulate these parameters will drive innovations in high-efficiency drug delivery systems and sustainable industrial processes.

Specific surface area vs Particle size Infographic

libmatt.com

libmatt.com