Raw meal is the finely ground mixture of raw materials like limestone, clay, and sand, essential for producing clinker in cement manufacturing. Clinker is the hardened, nodular material formed by heating raw meal in a kiln, which is then finely ground to create the final cement product.

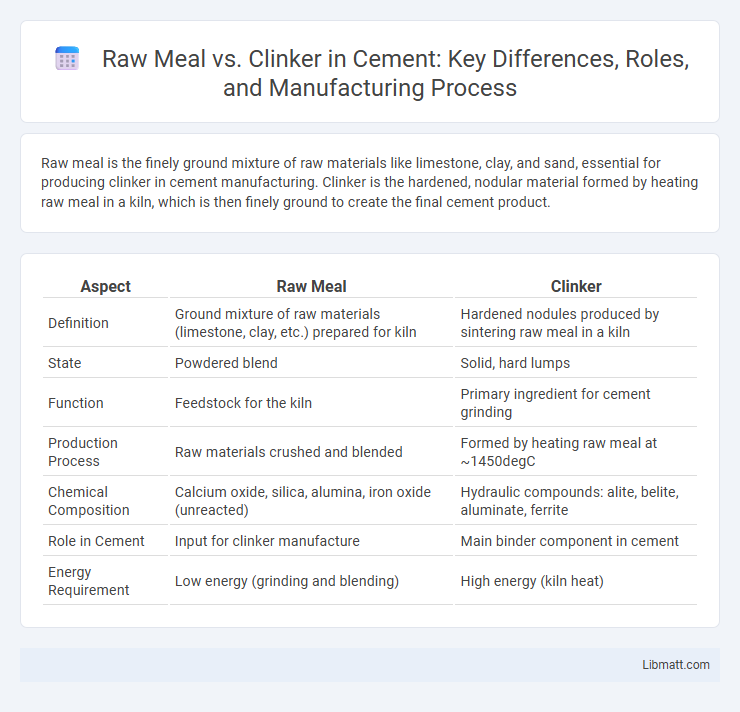

Table of Comparison

| Aspect | Raw Meal | Clinker |

|---|---|---|

| Definition | Ground mixture of raw materials (limestone, clay, etc.) prepared for kiln | Hardened nodules produced by sintering raw meal in a kiln |

| State | Powdered blend | Solid, hard lumps |

| Function | Feedstock for the kiln | Primary ingredient for cement grinding |

| Production Process | Raw materials crushed and blended | Formed by heating raw meal at ~1450degC |

| Chemical Composition | Calcium oxide, silica, alumina, iron oxide (unreacted) | Hydraulic compounds: alite, belite, aluminate, ferrite |

| Role in Cement | Input for clinker manufacture | Main binder component in cement |

| Energy Requirement | Low energy (grinding and blending) | High energy (kiln heat) |

Understanding Raw Meal: Definition and Composition

Raw meal is a finely ground mixture of raw materials, primarily composed of limestone, clay, silica, and iron oxide, used in cement manufacturing. It serves as the essential feedstock for the kiln, where it undergoes chemical transformations to form clinker. The precise composition of raw meal directly influences the quality and properties of the resulting clinker, impacting cement performance.

What is Clinker? Key Characteristics

Clinker is a solid material produced in the cement kiln through the calcination of raw meal, consisting primarily of calcium silicates, aluminates, and ferrites. It appears as dark gray nodules typically 3-25 mm in diameter, characterized by its high hardness and reactive phases crucial for cement hydration. The quality of clinker directly influences the strength and durability of the final cement product.

The Role of Raw Meal in Cement Production

Raw meal serves as the essential blend of limestone, clay, and other raw materials that undergoes heating in a rotary kiln to form clinker, which is the primary component in cement production. The chemical composition of the raw meal directly influences the quality, setting time, and durability of the resulting clinker, making precise control critical for optimal cement performance. Efficient mixing and homogenization of the raw meal ensure consistent kiln operation and energy consumption, ultimately impacting the environmental footprint of cement manufacturing.

How Clinker is Formed: The Manufacturing Process

Clinker forms during cement production by heating raw meal, a finely ground mixture of limestone, clay, and other materials, in a rotary kiln at temperatures reaching up to 1450degC. This intense heat causes chemical reactions such as calcination and sintering, resulting in the formation of nodules known as clinker. The clinker is then cooled and ground with gypsum to produce cement powder, a crucial step in the cement manufacturing process.

Chemical Differences: Raw Meal vs Clinker

Raw meal and clinker exhibit distinct chemical differences critical to cement manufacturing. Raw meal primarily consists of calcium carbonate (CaCO3), silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3) in raw, unprocessed form. Clinker, formed after the raw meal undergoes high-temperature calcination in a kiln, contains calcium silicates (alite and belite), calcium aluminates, and calcium ferrites, resulting in altered chemical phases and enhanced reactivity essential for cement strength development.

Energy Requirements: From Raw Meal to Clinker

Energy requirements for transforming raw meal into clinker are crucial in cement manufacturing, with the process demanding temperatures around 1450degC to induce chemical reactions and form clinker minerals. The calcination stage within the kiln consumes the majority of energy, typically accounting for 60-70% of total plant energy use, making it the most energy-intensive phase. Efficient heat recovery systems and optimized kiln operation can significantly reduce fuel consumption, lowering overall energy costs from raw meal to clinker production.

Quality Control Measures for Raw Meal and Clinker

Quality control measures for raw meal involve precise sampling and chemical analysis to ensure consistent particle size and chemical composition, crucial for stable kiln operation. For clinker, quality control focuses on monitoring mineralogical composition and physical properties like hardness and reactivity, ensuring the final product meets strength and durability standards. Your ability to maintain rigorous testing protocols directly impacts the efficiency and quality of the cement manufacturing process.

Impact on Final Cement Properties

Raw meal composition directly influences the mineral phases formed during clinker production, which determines cement's strength, durability, and setting time. Variations in raw meal chemistry can lead to differences in clinker mineralogy, impacting the final cement's hydration behavior and mechanical performance. Understanding your raw meal's characteristics ensures optimal clinker quality and improved cement properties for construction applications.

Environmental Considerations: Raw Meal and Clinker Production

Raw meal production consumes less energy compared to clinker production, significantly reducing carbon dioxide emissions in cement manufacturing. Clinker production involves high-temperature kiln processing, which releases large quantities of CO2 and other pollutants, making it the primary environmental concern. Optimizing your raw meal processing can help lower the overall environmental footprint of cement production by minimizing energy use and emissions.

Industry Trends: Innovations in Raw Meal and Clinker Processing

Advancements in raw meal and clinker processing emphasize energy efficiency and reduced CO2 emissions, with technologies like pre-calcination and vertical roller mills gaining traction in the cement industry. Innovations include incorporating alternative fuels into raw meal preparation and optimizing clinker grinding circuits to enhance product quality while minimizing environmental impact. Your facility can benefit from integrating these cutting-edge processes to improve sustainability and operational performance.

Raw Meal vs Clinker Infographic

libmatt.com

libmatt.com