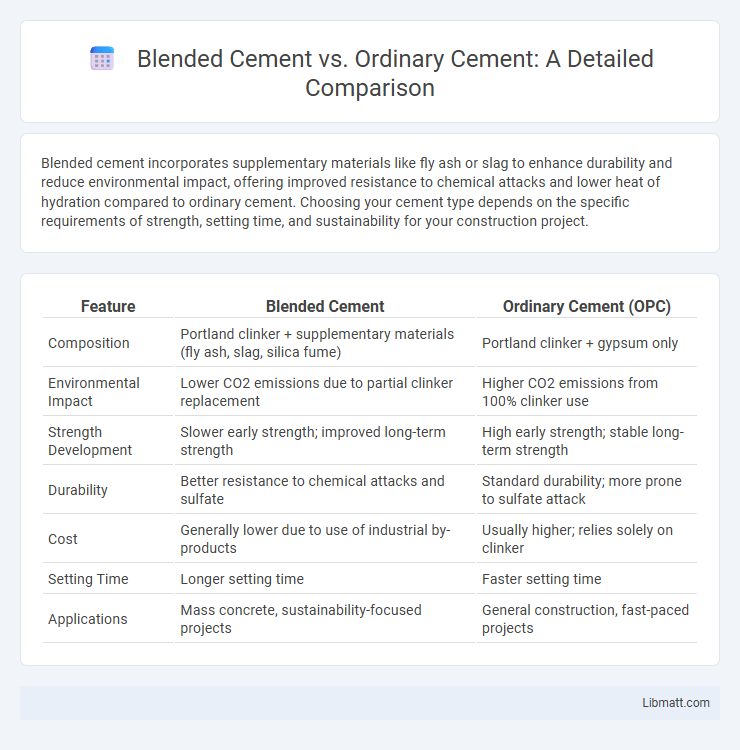

Blended cement incorporates supplementary materials like fly ash or slag to enhance durability and reduce environmental impact, offering improved resistance to chemical attacks and lower heat of hydration compared to ordinary cement. Choosing your cement type depends on the specific requirements of strength, setting time, and sustainability for your construction project.

Table of Comparison

| Feature | Blended Cement | Ordinary Cement (OPC) |

|---|---|---|

| Composition | Portland clinker + supplementary materials (fly ash, slag, silica fume) | Portland clinker + gypsum only |

| Environmental Impact | Lower CO2 emissions due to partial clinker replacement | Higher CO2 emissions from 100% clinker use |

| Strength Development | Slower early strength; improved long-term strength | High early strength; stable long-term strength |

| Durability | Better resistance to chemical attacks and sulfate | Standard durability; more prone to sulfate attack |

| Cost | Generally lower due to use of industrial by-products | Usually higher; relies solely on clinker |

| Setting Time | Longer setting time | Faster setting time |

| Applications | Mass concrete, sustainability-focused projects | General construction, fast-paced projects |

Introduction to Blended Cement and Ordinary Cement

Blended cement combines Ordinary Portland Cement (OPC) with supplementary materials such as fly ash, slag, or silica fume to enhance durability, reduce carbon footprint, and improve workability. Ordinary Cement, primarily composed of clinker and gypsum, is widely used for general construction but generates higher CO2 emissions during production. The inclusion of industrial by-products in blended cement contributes to sustainability by lowering energy consumption and improving mechanical properties compared to conventional OPC.

Composition Differences Between Blended and Ordinary Cement

Blended cement contains a mixture of Portland cement clinker and supplementary materials like fly ash, slag, or silica fume, whereas ordinary cement consists mainly of Portland cement clinker with minor gypsum additions. The inclusion of these supplementary materials in blended cement enhances durability, reduces heat of hydration, and improves sustainability by lowering carbon emissions. Your choice depends on the specific structural requirements and environmental considerations of your construction project.

Manufacturing Process Comparison

Blended cement is produced by mixing Portland cement clinker with supplementary cementitious materials such as fly ash, slag, or silica fume during the grinding process, reducing the amount of clinker required. Ordinary Portland Cement (OPC) is made by grinding clinker with a small amount of gypsum, without additional mineral additives. Your choice between blended and ordinary cement affects not only environmental impact but also the energy consumption and emissions associated with the manufacturing process.

Environmental Impact: Sustainability and Carbon Footprint

Blended cement significantly reduces environmental impact by incorporating industrial by-products such as fly ash, slag, or silica fume, which lowers CO2 emissions compared to Ordinary Portland Cement (OPC). The use of blended cement decreases the reliance on clinker, the primary source of carbon emissions in cement production, enhancing sustainability through resource conservation and waste repurposing. This reduction in carbon footprint makes blended cement a more eco-friendly choice for construction projects aiming to meet green building standards.

Mechanical Properties: Strength and Durability

Blended cement exhibits enhanced mechanical properties compared to ordinary cement, offering improved strength and durability due to the incorporation of supplementary materials like fly ash, slag, or silica fume. These additives reduce permeability and increase resistance to chemical attack, making blended cement ideal for structures subjected to harsh environmental conditions. Choosing blended cement for your construction project can result in longer-lasting, more resilient structures with superior performance over time.

Workability and Application Areas

Blended cement offers improved workability compared to ordinary cement due to its finer particles and reduced heat of hydration, making it ideal for large-scale concreting projects and structures exposed to harsh environmental conditions. Ordinary cement provides quicker setting times and higher early strength, suitable for repair works, precast elements, and smaller construction tasks requiring fast turnaround. Your choice depends on project requirements, with blended cement preferred for durability and sustainability, while ordinary cement suits applications demanding rapid strength development.

Cost Analysis: Blended vs Ordinary Cement

Blended cement typically offers cost advantages over ordinary cement due to the partial replacement of clinker with supplementary materials like fly ash, slag, or silica fume, which are less expensive and eco-friendly. This reduction in clinker content lowers production costs, resulting in a more economical option without compromising strength or durability. Your project can benefit financially by choosing blended cement, especially in large volumes, where savings accumulate significantly over time.

Performance in Different Climates

Blended cement exhibits superior performance in diverse climates due to its enhanced durability and resistance to chemical attacks compared to ordinary cement. It reduces heat of hydration, minimizing thermal cracking in hot climates while improving resistance to sulfate and chloride attacks in coastal or humid environments. Ordinary cement may suffer from faster degradation and reduced strength in extreme weather conditions, making blended cement a preferred choice for long-term structural integrity.

Standards and Certifications

Blended cement adheres to standards such as ASTM C595 and EN 197-1, which specify the proportions and performance criteria for mixtures including supplementary cementitious materials like fly ash or slag. Ordinary Portland cement complies with widely recognized standards like ASTM C150 and BS EN 197-1, ensuring consistent quality and strength for general construction use. Understanding these certifications helps you select the appropriate cement type that meets regulatory requirements and project specifications.

Choosing the Right Cement for Your Project

Blended cement combines Portland cement with supplementary materials like fly ash, slag, or silica fume, enhancing durability and reducing environmental impact compared to Ordinary Portland Cement (OPC). It offers improved resistance to chemical attack, lower heat of hydration, and better long-term strength, making it ideal for large-scale infrastructure or sustainable construction projects. Selecting blended cement over OPC depends on project requirements such as exposure conditions, environmental considerations, and desired performance characteristics.

Blended cement vs Ordinary cement Infographic

libmatt.com

libmatt.com