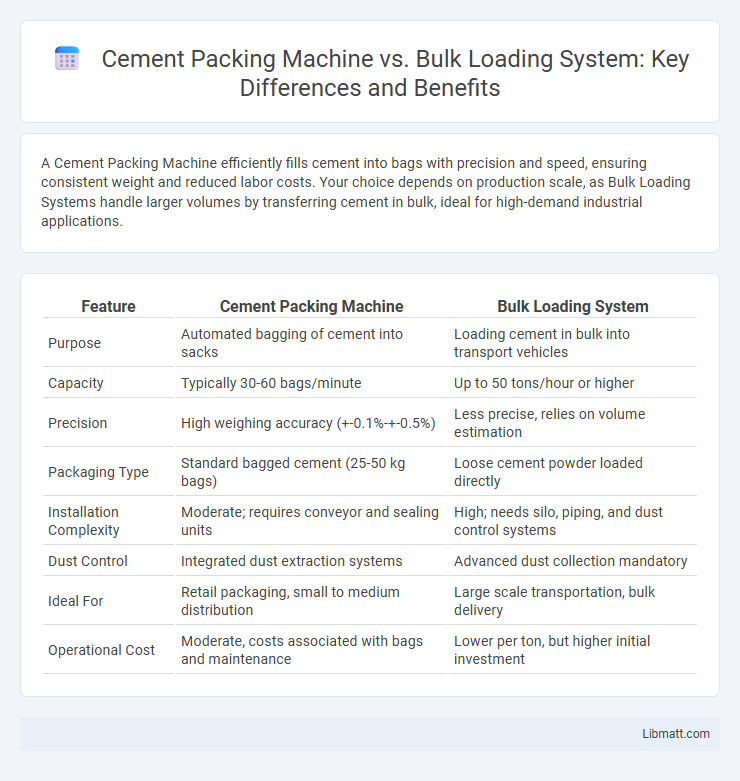

A Cement Packing Machine efficiently fills cement into bags with precision and speed, ensuring consistent weight and reduced labor costs. Your choice depends on production scale, as Bulk Loading Systems handle larger volumes by transferring cement in bulk, ideal for high-demand industrial applications.

Table of Comparison

| Feature | Cement Packing Machine | Bulk Loading System |

|---|---|---|

| Purpose | Automated bagging of cement into sacks | Loading cement in bulk into transport vehicles |

| Capacity | Typically 30-60 bags/minute | Up to 50 tons/hour or higher |

| Precision | High weighing accuracy (+-0.1%-+-0.5%) | Less precise, relies on volume estimation |

| Packaging Type | Standard bagged cement (25-50 kg bags) | Loose cement powder loaded directly |

| Installation Complexity | Moderate; requires conveyor and sealing units | High; needs silo, piping, and dust control systems |

| Dust Control | Integrated dust extraction systems | Advanced dust collection mandatory |

| Ideal For | Retail packaging, small to medium distribution | Large scale transportation, bulk delivery |

| Operational Cost | Moderate, costs associated with bags and maintenance | Lower per ton, but higher initial investment |

Introduction to Cement Packing Machine and Bulk Loading System

Cement packing machines automate the process of filling cement into bags with high precision, improving efficiency in cement manufacturing and distribution industries. Bulk loading systems are designed to transfer large volumes of cement directly into transport vehicles, such as tankers or silos, facilitating rapid and large-scale cement handling. Both technologies optimize cement logistics, with packing machines suited for packaged products and bulk systems tailored for mass transport and storage.

Key Differences Between Packing and Bulk Loading

Cement packing machines precisely fill and seal cement bags to ensure consistent weight and reduce spillage, enhancing storage and transport efficiency. Bulk loading systems transfer large quantities of cement directly into trucks or containers, prioritizing speed and volume over individual packaging. Key differences include packaging precision, operational scale, and suitability for distribution channels requiring either bagged products or bulk deliveries.

Advantages of Cement Packing Machines

Cement Packing Machines offer precise and consistent packaging, reducing material wastage and improving operational efficiency compared to Bulk Loading Systems. They enable easy handling, storage, and transportation of cement in smaller, customer-friendly quantities, enhancing market reach and sales flexibility. Your business benefits from minimized contamination risks and better quality control through automated packing processes.

Benefits of Bulk Loading Systems

Bulk loading systems offer significant efficiency advantages over traditional cement packing machines by enabling faster material transfer directly into silos or trucks, reducing manual handling and labor costs. These systems enhance operational productivity and minimize dust emissions, contributing to a safer and cleaner work environment. You benefit from streamlined workflows and improved material management, leading to lower downtime and increased overall output.

Cost Analysis: Packing Machine vs Bulk Loading

Cement packing machines generally involve higher upfront investment costs due to advanced automation and precision in filling bags, while bulk loading systems require lower initial expenses but often incur increased operational costs related to material handling and storage. Maintenance and labor costs tend to be higher for bulk loading systems due to manual interventions compared to the more streamlined and efficient packing machines. Over time, the total cost of ownership favors packing machines in high-volume production environments, as improved accuracy reduces material waste and enhances productivity.

Efficiency and Speed Comparison

Cement packing machines offer precise, consistent packaging with speeds typically ranging from 300 to 600 bags per hour, ideal for small to medium-scale operations requiring accuracy and minimal spillage. Bulk loading systems, designed for large-scale cement distribution, excel in efficiency by handling bulk quantities directly into transport vehicles, significantly reducing manual labor and increasing overall throughput speed. Your choice depends on whether speed and large volume handling or packaging precision is the priority for your cement processing needs.

Environmental Impact of Each System

Cement packing machines typically generate more solid waste due to packaging materials like plastic bags, contributing to landfill accumulation and environmental pollution. Bulk loading systems reduce packaging waste by transporting cement in large quantities directly to storage or transport units, significantly lowering plastic use and minimizing carbon emissions associated with manufacturing and disposing of bags. While bulk loading requires airtight systems to prevent dust leakage and air pollution, advances in sealing technology have made it environmentally superior by reducing particulate matter release compared to traditional packed cement handling.

Suitability for Different Cement Plant Operations

Cement packing machines are ideal for small to medium-sized cement plants requiring precise, efficient bagging with high accuracy and minimal labor. Bulk loading systems suit large-scale cement operations that demand rapid, high-volume transfer of loose cement to trucks or silos, optimizing logistics and reducing manual handling. Selecting the appropriate system depends on production capacity, storage method, and distribution logistics specific to the plant's operational scale.

Maintenance and Operational Requirements

Cement packing machines require regular calibration and timely replacement of worn-out sealing components to maintain accuracy and prevent material spillage. Bulk loading systems demand consistent inspection of conveyor belts and dust control mechanisms to ensure smooth material flow and environmental compliance. Understanding these maintenance and operational requirements helps optimize Your equipment's efficiency and longevity.

Future Trends in Cement Packaging and Loading

Future trends in cement packaging and loading emphasize automation and sustainability, with cement packing machines integrating advanced sensors and AI to enhance precision and reduce waste. Bulk loading systems are evolving to incorporate real-time monitoring and IoT connectivity, enabling seamless inventory management and faster dispatch. Both technologies increasingly prioritize eco-friendly materials and energy-efficient operations to meet stringent environmental regulations and optimize supply chain efficiency.

Cement Packing Machine vs Bulk Loading System Infographic

libmatt.com

libmatt.com