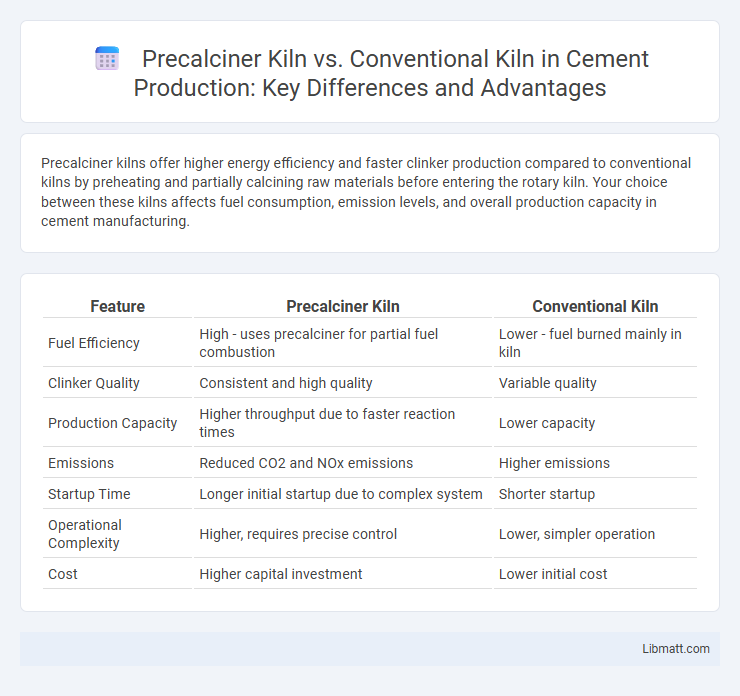

Precalciner kilns offer higher energy efficiency and faster clinker production compared to conventional kilns by preheating and partially calcining raw materials before entering the rotary kiln. Your choice between these kilns affects fuel consumption, emission levels, and overall production capacity in cement manufacturing.

Table of Comparison

| Feature | Precalciner Kiln | Conventional Kiln |

|---|---|---|

| Fuel Efficiency | High - uses precalciner for partial fuel combustion | Lower - fuel burned mainly in kiln |

| Clinker Quality | Consistent and high quality | Variable quality |

| Production Capacity | Higher throughput due to faster reaction times | Lower capacity |

| Emissions | Reduced CO2 and NOx emissions | Higher emissions |

| Startup Time | Longer initial startup due to complex system | Shorter startup |

| Operational Complexity | Higher, requires precise control | Lower, simpler operation |

| Cost | Higher capital investment | Lower initial cost |

Introduction to Cement Kilns

Precalciner kilns are advanced cement production systems integrating a separate calcining zone before the rotary kiln, enhancing fuel efficiency and reducing emissions compared to conventional kilns. Conventional kilns perform clinker formation entirely within the rotary kiln, resulting in longer residence times and higher fuel consumption. The distinctive design of precalciner kilns allows up to 70-75% of the fuel combustion to occur in the precalciner, optimizing thermal performance and increasing overall kiln capacity.

Overview of Conventional Kiln Technology

Conventional kiln technology relies on direct flame contact within long, rotating cylinders to heat materials, primarily used in cement manufacturing for clinker production. This process involves the decomposition and chemical transformation of raw materials at high temperatures over extended residence times. Compared to precalciner kilns, conventional kilns feature lower fuel efficiency and higher emissions due to less effective heat utilization and the absence of a separate fuel combustion chamber.

What is a Precalciner Kiln?

A Precalciner Kiln is an advanced type of cement kiln designed to improve thermal efficiency by preheating and partially calcining raw materials before they enter the main rotary kiln. This process significantly reduces fuel consumption and increases production capacity compared to Conventional Kilns, which rely solely on the rotary kiln for calcination. Your cement manufacturing process benefits from lower emissions and enhanced energy savings when utilizing a Precalciner Kiln system.

Key Differences Between Precalciner and Conventional Kilns

Precalciner kilns feature a separate combustion chamber where a large portion of fuel is burned before entering the rotary kiln, resulting in higher fuel efficiency and lower emissions compared to conventional kilns. Conventional kilns rely solely on the rotary kiln for fuel combustion, leading to longer retention times and higher energy consumption. You can significantly reduce operational costs and environmental impact by choosing a precalciner kiln for cement production.

Energy Efficiency Comparison

Precalciner kilns achieve significantly higher energy efficiency than conventional kilns by preheating raw materials and enabling more complete combustion before entering the main kiln chamber, resulting in fuel savings of up to 30%. Conventional kilns consume more energy due to longer residence times and less optimized heat recovery systems, leading to increased fuel consumption and higher CO2 emissions. Your choice of a precalciner kiln can substantially reduce operational costs while minimizing environmental impact through improved thermal efficiency.

Environmental Impact and Emissions

Precalciner kilns significantly reduce environmental impact by lowering CO2 emissions through improved fuel efficiency and partial clinker calcination before entering the main kiln. Conventional kilns typically emit higher levels of pollutants, including NOx and particulate matter, due to longer heating stages and incomplete combustion. Your choice of precalciner kiln can enhance sustainability efforts by minimizing greenhouse gases and reducing energy consumption.

Operational Costs and Maintenance

Precalciner kilns significantly reduce operational costs by enhancing fuel efficiency and minimizing energy consumption compared to conventional kilns. Maintenance requirements are lower due to advanced process control and reduced thermal stress, leading to extended equipment lifespan. Your choice of kiln can impact long-term expenses, with precalciner technology offering substantial savings in both fuel and upkeep.

Production Capacity and Output Quality

Precalciner kilns offer higher production capacity by optimizing fuel combustion and allowing for faster clinker formation, resulting in increased throughput compared to conventional kilns. The enhanced temperature control in precalciner kilns improves output quality by producing more uniform clinker with lower levels of impurities. This leads to better cement performance and reduced energy consumption per ton of clinker produced.

Technological Advancements in Kiln Design

Precalciner kilns incorporate advanced combustion technology that allows for higher fuel efficiency and lower emissions compared to conventional kilns, which rely on longer heat transmission times. The integration of separate calcination zones in precalciner kilns enhances thermal energy utilization, resulting in faster clinker production and reduced energy consumption. Modern precalciner designs also support the use of alternative fuels, contributing to sustainable cement manufacturing practices.

Choosing the Right Kiln for Your Cement Plant

Selecting the appropriate kiln for your cement plant hinges on efficiency, fuel consumption, and environmental impact. Precalciner kilns offer higher thermal efficiency and lower CO2 emissions due to their staged combustion and advanced heat recovery systems compared to conventional kilns. Evaluating project scale, fuel availability, and operational costs is critical in determining whether the modern precalciner technology or the traditional rotary kiln suits your plant's production goals.

Precalciner Kiln vs Conventional Kiln Infographic

libmatt.com

libmatt.com