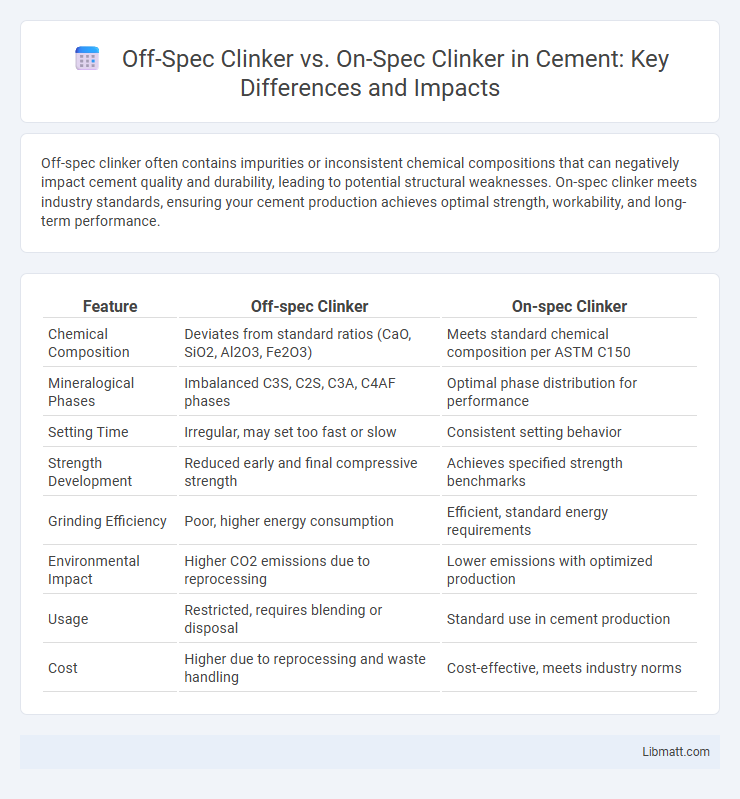

Off-spec clinker often contains impurities or inconsistent chemical compositions that can negatively impact cement quality and durability, leading to potential structural weaknesses. On-spec clinker meets industry standards, ensuring your cement production achieves optimal strength, workability, and long-term performance.

Table of Comparison

| Feature | Off-spec Clinker | On-spec Clinker |

|---|---|---|

| Chemical Composition | Deviates from standard ratios (CaO, SiO2, Al2O3, Fe2O3) | Meets standard chemical composition per ASTM C150 |

| Mineralogical Phases | Imbalanced C3S, C2S, C3A, C4AF phases | Optimal phase distribution for performance |

| Setting Time | Irregular, may set too fast or slow | Consistent setting behavior |

| Strength Development | Reduced early and final compressive strength | Achieves specified strength benchmarks |

| Grinding Efficiency | Poor, higher energy consumption | Efficient, standard energy requirements |

| Environmental Impact | Higher CO2 emissions due to reprocessing | Lower emissions with optimized production |

| Usage | Restricted, requires blending or disposal | Standard use in cement production |

| Cost | Higher due to reprocessing and waste handling | Cost-effective, meets industry norms |

Introduction to Clinker Specifications

Clinker specifications define the chemical and physical properties required for producing high-quality cement, impacting strength and durability. Off-spec clinker falls outside these standards due to variations in parameters like lime saturation or free lime content, leading to potential inefficiencies in cement performance. Ensuring your clinker meets industry specifications is crucial for maintaining product consistency and construction reliability.

What is On-spec Clinker?

On-spec clinker refers to clinker that meets the required chemical composition and physical quality standards specified by industry regulations and customer contracts, ensuring optimal performance in cement production. This includes consistent levels of key components such as tricalcium silicate (C3S), dicalcium silicate (C2S), and minimal impurities that affect clinker reactivity and strength development. On-spec clinker guarantees uniformity in cement manufacturing processes, leading to high-quality end products with reliable durability and structural integrity.

Defining Off-spec Clinker

Off-spec clinker refers to cement clinker that fails to meet specified chemical, physical, or performance criteria established by industry standards like ASTM or EN. It often exhibits deviations in composition, such as improper silica or alumina content, leading to reduced strength or durability in the final cement product. Identifying off-spec clinker early is crucial to maintain quality control and avoid costly downstream processing issues in cement manufacturing.

Key Differences Between Off-spec and On-spec Clinker

Off-spec clinker differs from on-spec clinker primarily in chemical composition, physical properties, and performance standards, often leading to reduced cement quality and potential structural issues. On-spec clinker meets the industry standards for parameters like hardness, chemical balance, and fineness, ensuring optimal cement production and durability. Understanding these key differences helps you make informed decisions in sourcing clinker that aligns with your project's quality requirements.

Chemical Composition: On-spec vs Off-spec

On-spec clinker meets the standardized chemical composition requirements, typically containing balanced levels of calcium oxide (CaO), silicon dioxide (SiO2), aluminum oxide (Al2O3), and iron oxide (Fe2O3) essential for optimal cement performance. Off-spec clinker deviates from these specifications, often exhibiting abnormal variations such as excessive free lime (CaO) or insufficient silica, which can negatively affect clinker reactivity and cement strength. Ensuring your clinker adheres to on-spec chemical composition maintains product quality and consistency in cement manufacturing.

Physical Properties Comparison

Off-spec clinker typically exhibits variations in physical properties such as increased porosity, irregular particle size distribution, and higher moisture content compared to on-spec clinker. On-spec clinker maintains consistent hardness, uniform particle morphology, and optimal chemical composition, which ensures predictable hydration and strength development in cement. These physical discrepancies in off-spec clinker can lead to reduced compressive strength and durability in the final cement product.

Impact on Cement Quality and Performance

Off-spec clinker contains variations in chemical composition or physical properties that can negatively affect cement quality by causing inconsistent setting times and reduced strength development. On-spec clinker meets stringent industry standards, ensuring optimal cement performance in terms of durability, workability, and hydration characteristics. Your choice between off-spec and on-spec clinker directly influences the reliability and long-term performance of the final cement product.

Causes of Off-spec Clinker Production

Off-spec clinker production primarily results from improper raw material proportions, inconsistent kiln temperature control, and incomplete or improper clinkerization processes. Variations in the chemical composition, such as excess silica or inadequate lime saturation, disrupt the formation of desired mineral phases, leading to substandard clinker quality. Addressing these issues in your raw feed and kiln operation can significantly reduce off-spec clinker occurrences and improve cement performance.

Industrial Handling of Off-spec Clinker

Industrial handling of off-spec clinker requires specialized processes to ensure compliance with quality standards and minimize environmental impact. Off-spec clinker often undergoes reprocessing, blending, or alternative use in lower-grade cement products to optimize resource utilization and reduce waste. Managing your off-spec clinker efficiently enables cost savings and supports sustainable industrial practices while maintaining operational productivity.

Economic and Environmental Implications

Off-spec clinker, characterized by lower quality or inconsistent chemical composition, leads to increased production costs due to additional processing and potential penalties during cement manufacturing. This inefficiency not only raises operational expenses but also causes higher CO2 emissions from reprocessing and energy wastage, exacerbating environmental impacts. In contrast, on-spec clinker ensures optimal kiln operation, minimizes waste, and supports sustainability goals through reduced fuel consumption and lower greenhouse gas emissions.

Off-spec Clinker vs On-spec Clinker Infographic

libmatt.com

libmatt.com