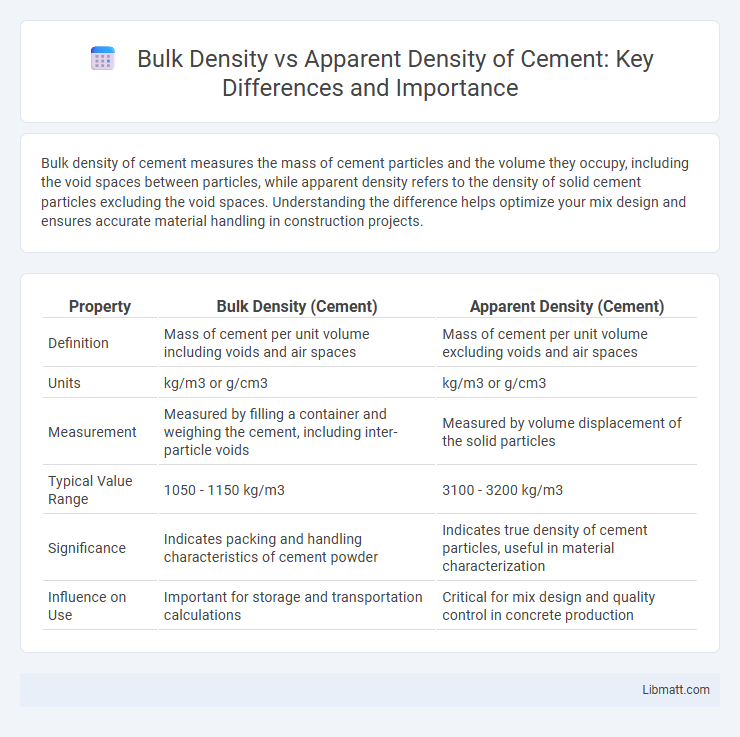

Bulk density of cement measures the mass of cement particles and the volume they occupy, including the void spaces between particles, while apparent density refers to the density of solid cement particles excluding the void spaces. Understanding the difference helps optimize your mix design and ensures accurate material handling in construction projects.

Table of Comparison

| Property | Bulk Density (Cement) | Apparent Density (Cement) |

|---|---|---|

| Definition | Mass of cement per unit volume including voids and air spaces | Mass of cement per unit volume excluding voids and air spaces |

| Units | kg/m3 or g/cm3 | kg/m3 or g/cm3 |

| Measurement | Measured by filling a container and weighing the cement, including inter-particle voids | Measured by volume displacement of the solid particles |

| Typical Value Range | 1050 - 1150 kg/m3 | 3100 - 3200 kg/m3 |

| Significance | Indicates packing and handling characteristics of cement powder | Indicates true density of cement particles, useful in material characterization |

| Influence on Use | Important for storage and transportation calculations | Critical for mix design and quality control in concrete production |

Introduction to Bulk Density and Apparent Density

Bulk density in cement refers to the mass of cement particles per unit volume, including the air spaces between particles, typically measured in kilograms per cubic meter (kg/m3). Apparent density, also known as particle density, represents the mass of the solid cement particles per unit volume excluding the voids, providing a higher value than bulk density. Understanding these densities is crucial for optimizing cement quality, mix design, and ensuring consistency in construction applications.

Definition of Bulk Density in Cement

Bulk density in cement refers to the mass of cement particles contained within a unit volume, including the air spaces between the particles. This measurement is crucial for understanding the packing, flow properties, and storage requirements of cement, as it directly affects the material's handling and mixing consistency. Your knowledge of bulk density helps optimize the cement's performance in construction applications by ensuring accurate proportioning and quality control.

Definition of Apparent Density in Cement

Apparent density in cement refers to the mass of the cement particles divided by the total volume they occupy, including the spaces between particles but excluding the internal pore volume. It is measured by filling a known volume with cement and weighing it, reflecting the packing efficiency and particle arrangement. Understanding apparent density helps you assess cement quality and optimize mix proportions for construction projects.

Key Differences Between Bulk Density and Apparent Density

Bulk density of cement measures the mass of cement particles, including the voids between them, per unit volume, while apparent density refers to the density of the solid material excluding open pores and voids. Bulk density is influenced by particle packing, compaction, and moisture content, whereas apparent density is an inherent property of the cement material itself. Understanding these key differences is essential for quality control and determining cement's behavior in concrete mixtures.

Factors Influencing Bulk Density of Cement

Bulk density of cement is influenced by particle size distribution, moisture content, and compaction level during storage or handling. Irregular particle shape and the presence of air voids also affect the packing efficiency, altering the measured bulk density. Understanding these factors helps you accurately assess cement quality and optimize material handling processes.

Factors Influencing Apparent Density of Cement

Apparent density of cement is primarily influenced by particle size distribution, moisture content, and air voids within the powder. Finer particles increase the packing efficiency, raising apparent density, while moisture causes agglomeration that reduces it. Storage conditions and handling methods also affect the compaction level and in turn the apparent density of cement.

Importance of Bulk Density in Construction

Bulk density of cement is a critical parameter that affects the mix design, strength, and durability of concrete structures, influencing the workability and compaction of the material. It determines the weight per unit volume, including the voids between particles, which directly impacts the packaging, transportation, and storage efficiency of cement on construction sites. Accurate measurement of bulk density ensures consistent quality control and optimal material utilization, reducing costs and enhancing the structural integrity of buildings and infrastructure.

Importance of Apparent Density in Cement Applications

Apparent density in cement is critical for accurately determining the volume and strength properties essential in construction applications. It reflects the mass of cement particles per unit volume, including the pore spaces, which directly influences the mixture proportions and concrete durability. Proper assessment of apparent density ensures consistent quality control and structural integrity in cement-based materials.

Methods for Measuring Bulk and Apparent Density

Bulk density of cement is typically measured using a standard container method, where a known volume of loose cement is filled without compaction and weighed to calculate density. Apparent density is determined by measuring the mass of cement particles divided by the volume excluding open pores and voids, often using a pycnometer or gas displacement method for precise particle volume determination. Understanding these measurement techniques helps you accurately assess cement quality and consistency for construction applications.

Practical Implications for Cement Selection and Quality Control

Understanding bulk density and apparent density is crucial for cement selection and quality control, as bulk density reflects the mass per unit volume including voids, affecting packing and handling characteristics. Apparent density measures the solid particle density excluding pores, providing insights into cement fineness and compaction properties. You can optimize mix designs and ensure consistent product performance by accurately assessing both densities during quality control processes.

Bulk Density vs Apparent Density (Cement) Infographic

libmatt.com

libmatt.com