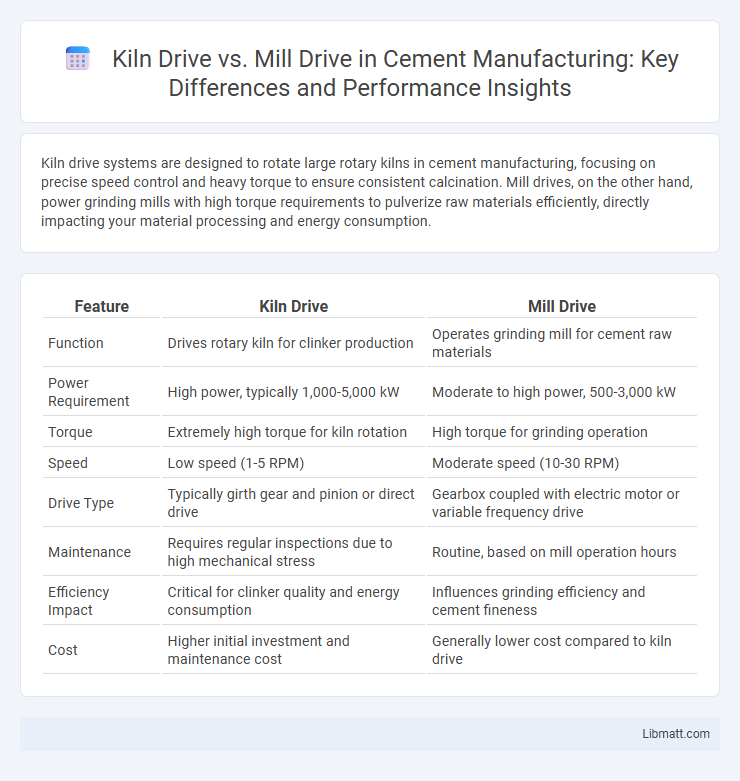

Kiln drive systems are designed to rotate large rotary kilns in cement manufacturing, focusing on precise speed control and heavy torque to ensure consistent calcination. Mill drives, on the other hand, power grinding mills with high torque requirements to pulverize raw materials efficiently, directly impacting your material processing and energy consumption.

Table of Comparison

| Feature | Kiln Drive | Mill Drive |

|---|---|---|

| Function | Drives rotary kiln for clinker production | Operates grinding mill for cement raw materials |

| Power Requirement | High power, typically 1,000-5,000 kW | Moderate to high power, 500-3,000 kW |

| Torque | Extremely high torque for kiln rotation | High torque for grinding operation |

| Speed | Low speed (1-5 RPM) | Moderate speed (10-30 RPM) |

| Drive Type | Typically girth gear and pinion or direct drive | Gearbox coupled with electric motor or variable frequency drive |

| Maintenance | Requires regular inspections due to high mechanical stress | Routine, based on mill operation hours |

| Efficiency Impact | Critical for clinker quality and energy consumption | Influences grinding efficiency and cement fineness |

| Cost | Higher initial investment and maintenance cost | Generally lower cost compared to kiln drive |

Introduction to Kiln Drive and Mill Drive

Kiln drive and mill drive are critical components in cement and mining industries, responsible for the rotation of kilns and mills respectively. Kiln drives typically handle the slow, heavy rotation of rotary kilns with precise torque control, while mill drives power grinding mills with higher speed and variable load capacities. Understanding the functional and operational differences enhances equipment performance and energy efficiency in industrial processes.

Key Functions of Kiln Drive Systems

Kiln drive systems are essential for rotating rotary kilns in industries such as cement manufacturing, ensuring precise control of speed and torque to maintain optimal processing conditions. These drives convert electrical energy into mechanical motion, enabling consistent kiln rotation that supports thermal treatment of materials. Your choice of kiln drive affects efficiency, operational stability, and maintenance requirements, distinguishing it from mill drive systems focused primarily on grinding applications.

Primary Roles of Mill Drive Systems

Mill drive systems primarily provide the necessary torque and rotational speed to operate grinding mills efficiently, impacting the overall milling process and throughput. These systems control the rotational movement of the mill's drum or ball charge, ensuring material is finely ground for subsequent processing stages. Understanding the mill drive's function can help optimize your plant's performance and energy consumption.

Design Differences Between Kiln Drives and Mill Drives

Kiln drives typically feature a high-torque, low-speed design with large gear reducers and robust pinion gears to handle the heavy load and continuous rotary motion of cement kilns. Mill drives, in contrast, utilize variable speed drives with more compact gearboxes optimized for the dynamic loading and frequent speed adjustments required in grinding mills. Your choice between kiln drives and mill drives should consider these design differences to ensure optimal performance and durability in your industrial applications.

Mechanical Components Comparison

Kiln drives typically include large gear assemblies, thrust rollers, and girth gears designed for high torque and low-speed rotation, whereas mill drives focus on variable speed motors, pinions, and ring gears to handle fluctuating loads and rotational speeds. The mechanical components of kiln drives emphasize durability and stability under continuous operation, while mill drives prioritize adaptability and shock load resistance. Your choice depends on matching the drive's mechanical robustness to the specific operational demands of either rotary kilns or grinding mills.

Power and Torque Requirements

Kiln drives require high torque at low speeds to rotate large rotary kilns, often demanding torque values in the range of several hundred thousand Nm and power ratings exceeding several megawatts to manage heavy loads and maintain consistent rotation. Mill drives, particularly those for grinding mills, also necessitate substantial torque but typically operate at slightly higher speeds, with power requirements frequently ranging from 1 MW to over 20 MW depending on mill size and operational capacity. Both kiln and mill drives must deliver robust power and torque outputs to ensure continuous, efficient processing, yet kiln drives emphasize slow rotational speed with maximum torque, whereas mill drives balance moderate speed and high torque for grinding operations.

Control and Automation Systems

Kiln drive and mill drive systems utilize advanced control and automation technologies tailored to their specific operational requirements; kiln drives often implement continuous feedback loops and variable frequency drives for precise rotational speed control under high thermal stress conditions. Mill drives leverage sophisticated torque control algorithms and load monitoring systems to optimize grinding efficiency and prevent mechanical overload. Both systems integrate programmable logic controllers (PLCs) and real-time data acquisition for enhanced process stability and predictive maintenance.

Typical Applications in Industry

Kiln drives are commonly used in cement production, lime manufacturing, and refractory materials processing, where continuous rotation of large rotary kilns ensures uniform heating of raw materials. Mill drives are primarily applied in grinding operations within mining, mineral processing, and cement industries, facilitating the comminution of ores and clinker through ball mills and SAG mills. Depending on Your operational needs, selecting the appropriate drive system maximizes efficiency in heavy-duty rotary equipment.

Maintenance Considerations for Kiln vs Mill Drives

Maintenance considerations for kiln drives emphasize regular inspection of gearboxes, lubrication systems, and alignment to prevent excessive wear and overheating. Mill drives require frequent monitoring of electrical components, such as motors and frequency converters, alongside mechanical parts like couplings and gear teeth to ensure operational stability. Both systems demand predictive maintenance techniques to minimize downtime, but kiln drives often experience higher thermal stresses, requiring specialized cooling and sealing solutions.

Selecting the Right Drive: Factors to Consider

Selecting the right drive for kiln and mill systems involves evaluating power requirements, torque characteristics, and operating speeds to ensure optimal performance and energy efficiency. Kiln drives typically demand high torque and variable speed control to accommodate thermal processing, while mill drives prioritize consistent torque and load handling for grinding operations. Consideration of maintenance needs, system compatibility, and control precision plays a crucial role in achieving reliable and cost-effective drive solutions.

Kiln drive vs Mill drive Infographic

libmatt.com

libmatt.com