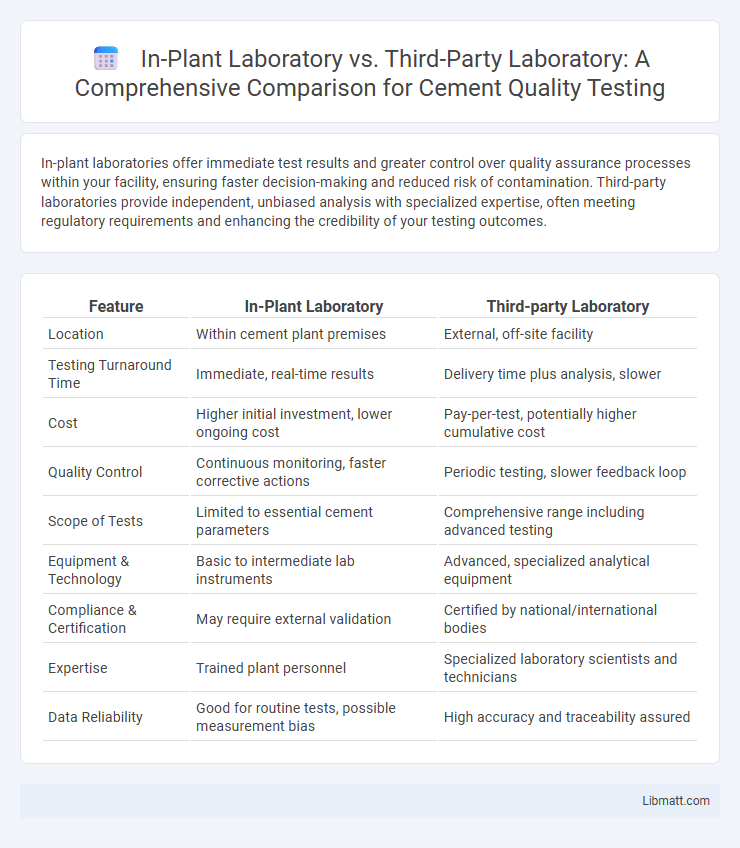

In-plant laboratories offer immediate test results and greater control over quality assurance processes within your facility, ensuring faster decision-making and reduced risk of contamination. Third-party laboratories provide independent, unbiased analysis with specialized expertise, often meeting regulatory requirements and enhancing the credibility of your testing outcomes.

Table of Comparison

| Feature | In-Plant Laboratory | Third-party Laboratory |

|---|---|---|

| Location | Within cement plant premises | External, off-site facility |

| Testing Turnaround Time | Immediate, real-time results | Delivery time plus analysis, slower |

| Cost | Higher initial investment, lower ongoing cost | Pay-per-test, potentially higher cumulative cost |

| Quality Control | Continuous monitoring, faster corrective actions | Periodic testing, slower feedback loop |

| Scope of Tests | Limited to essential cement parameters | Comprehensive range including advanced testing |

| Equipment & Technology | Basic to intermediate lab instruments | Advanced, specialized analytical equipment |

| Compliance & Certification | May require external validation | Certified by national/international bodies |

| Expertise | Trained plant personnel | Specialized laboratory scientists and technicians |

| Data Reliability | Good for routine tests, possible measurement bias | High accuracy and traceability assured |

Introduction to In-Plant and Third-Party Laboratories

In-Plant Laboratories operate within the manufacturing or production facility, enabling immediate testing and quality control to ensure products meet specifications before leaving the plant. Third-Party Laboratories provide independent testing services outside the production environment, offering unbiased results and compliance verification for regulatory standards. Your choice between these options impacts turnaround time, cost, and confidence in product quality assurance.

Key Differences Between In-Plant and Third-Party Labs

In-plant laboratories provide immediate testing and quality control within your production facility, ensuring real-time data and rapid decision-making. Third-party laboratories offer independent, unbiased testing services with advanced equipment and specialized expertise, crucial for regulatory compliance and certification. Choosing between them depends on your need for speed, control, and the level of external validation required.

Cost Comparison: In-Plant vs Third-Party Laboratories

In-plant laboratories generally offer lower ongoing testing costs by eliminating subcontractor fees and reducing turnaround times, making them cost-effective for high-volume or routine testing needs. Third-party laboratories incur higher expenses due to service fees, transportation costs, and potential delays, which can increase overall testing budgets for companies with frequent or urgent sample analysis. However, initial investment and operational expenses of in-plant labs may be higher, necessitating thorough cost-benefit analysis based on testing volume and required turnaround times.

Turnaround Time and Results Efficiency

In-plant laboratories typically offer faster turnaround times due to on-site sample analysis, reducing delays associated with transport and external scheduling. This proximity enables real-time adjustments and immediate decision-making, enhancing overall results efficiency. Conversely, third-party laboratories may provide comprehensive testing capabilities and specialized expertise but often involve longer processing times that can impact project timelines.

Quality Control and Assurance Standards

In-plant laboratories maintain direct control over quality control and assurance standards by enabling immediate testing and real-time monitoring within the production environment, ensuring faster detection of defects and compliance with internal specifications. Third-party laboratories offer unbiased, certified testing services that adhere to standardized protocols and industry regulations, often providing a higher level of external validation and traceability. Your choice between in-plant and third-party laboratories significantly impacts the accuracy, timeliness, and credibility of quality control processes in manufacturing.

Data Security and Confidentiality Concerns

In-plant laboratories offer enhanced data security and confidentiality by maintaining direct control over sensitive information, minimizing risks associated with data breaches or unauthorized access. Third-party laboratories may require data sharing across external networks, increasing exposure to potential cyber threats and confidentiality issues. Ensuring your data stays protected requires evaluating the security protocols and compliance measures of the chosen laboratory.

Flexibility and Customization in Testing

In-plant laboratories offer higher flexibility and customization in testing by allowing immediate adjustments to protocols based on production needs and real-time feedback. Third-party laboratories follow standardized procedures that may limit customization but provide consistent, accredited testing results crucial for regulatory compliance. The proximity of in-plant labs enables rapid testing cycles and tailored analyses, enhancing operational efficiency compared to the fixed schedules and generalized testing frameworks typical of third-party facilities.

Regulatory Compliance and Accreditation

In-plant laboratories offer direct control over regulatory compliance, ensuring rapid adherence to industry standards such as ISO/IEC 17025, while third-party laboratories provide independent accreditation that enhances credibility and impartiality. Your choice impacts the reliability of test results and regulatory acceptance, with third-party labs often preferred for unbiased third-party certification. Both must maintain stringent documentation and quality management systems to meet regulatory requirements effectively.

Case Studies: Industry Applications and Outcomes

Case studies reveal that in-plant laboratories streamline quality control processes in manufacturing industries, resulting in faster decision-making and reduced production downtime. Third-party laboratories excel in providing unbiased testing outcomes and regulatory compliance across pharmaceuticals and food sectors, enhancing product credibility and market trust. Your choice between these options impacts operational efficiency, cost, and compliance depending on industry-specific needs.

Choosing the Right Laboratory Solution for Your Business

Selecting between an in-plant laboratory and a third-party laboratory depends on factors such as cost efficiency, turnaround time, and control over testing processes. In-plant laboratories offer faster results and greater control, ideal for businesses requiring immediate quality assurance and process adjustments. Third-party laboratories provide unbiased testing and specialized expertise, making them suitable for compliance, certification, and complex analyses beyond the scope of in-house capabilities.

In-Plant Laboratory vs Third-party Laboratory Infographic

libmatt.com

libmatt.com