Single shaft mixers provide efficient mixing for viscous materials and are ideal for applications requiring gentle blending, while twin shaft mixers offer powerful mixing with high shear forces suitable for rapid, thorough blending of heavy-duty or complex mixtures. Your choice depends on material characteristics and processing requirements, ensuring optimal mixing performance and energy efficiency.

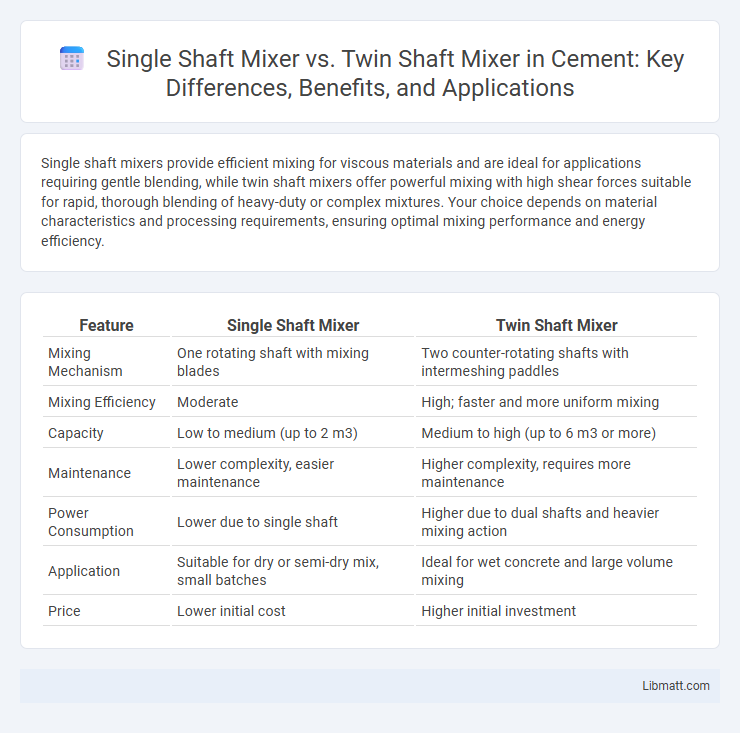

Table of Comparison

| Feature | Single Shaft Mixer | Twin Shaft Mixer |

|---|---|---|

| Mixing Mechanism | One rotating shaft with mixing blades | Two counter-rotating shafts with intermeshing paddles |

| Mixing Efficiency | Moderate | High; faster and more uniform mixing |

| Capacity | Low to medium (up to 2 m3) | Medium to high (up to 6 m3 or more) |

| Maintenance | Lower complexity, easier maintenance | Higher complexity, requires more maintenance |

| Power Consumption | Lower due to single shaft | Higher due to dual shafts and heavier mixing action |

| Application | Suitable for dry or semi-dry mix, small batches | Ideal for wet concrete and large volume mixing |

| Price | Lower initial cost | Higher initial investment |

Introduction to Industrial Mixers

Single shaft mixers feature a single rotating shaft with attached mixing blades that provide efficient blending for viscous materials and moderate mixing tasks, commonly used in industries like construction and food processing. Twin shaft mixers employ two parallel shafts with intermeshing paddles, offering intense mixing action and faster blending suited for heavy-duty applications such as concrete production and chemical processing. Industrial mixers vary by design and function, with single shaft models optimized for homogeneity in medium-viscosity materials, while twin shaft mixers handle high-volume, high-viscosity mixtures requiring robust mechanical action.

Overview of Single Shaft Mixers

Single shaft mixers feature a single rotating shaft equipped with mixing paddles or blades designed for efficient blending and thorough homogenization of materials. They excel in handling highly viscous substances, providing consistent mixing of pastes, doughs, and slurries in industries such as food processing, pharmaceuticals, and construction. These mixers offer advantages in energy efficiency, simplified maintenance, and uniform heat distribution compared to other types like twin shaft mixers.

Overview of Twin Shaft Mixers

Twin shaft mixers are industrial machines designed for high-efficiency mixing, featuring two horizontal shafts with intermeshing paddles or blades that provide rapid and thorough blending of materials. These mixers excel in handling heavy-duty mixing tasks, such as concrete and refractory materials, due to their robust construction and powerful mixing action. Your production processes benefit from the twin shaft mixer's ability to deliver uniform consistency and shorter mixing cycles compared to single shaft mixers.

Key Differences Between Single and Twin Shaft Mixers

Single shaft mixers feature a single rotating shaft with mixing paddles, offering gentle and homogeneous blending ideal for low to medium viscosity materials, while twin shaft mixers employ two counter-rotating shafts for intense mixing suitable for high-viscosity or fiber-reinforced materials. The operational speed of single shaft mixers is generally slower but consumes less energy, contrasting with the high-speed, high-torque twin shaft mixers designed for rapid and thorough mixing processes. Maintenance complexity and wear rates are typically higher in twin shaft mixers due to their dual mechanism, whereas single shaft mixers benefit from simpler design and easier cleaning.

Mixing Efficiency and Homogeneity

Single shaft mixers deliver efficient mixing by using one rotating shaft with attached paddles or blades, achieving moderate homogeneity ideal for less complex materials. Twin shaft mixers enhance mixing efficiency by employing two counter-rotating shafts that generate powerful shear forces, resulting in superior homogeneity and faster processing times for dense or cohesive materials. Your choice depends on the required mixing precision and material characteristics, with twin shaft mixers offering higher consistency for demanding applications.

Energy Consumption and Operational Costs

Single shaft mixers generally consume less energy due to their simpler design, making operational costs lower in applications requiring homogeneous mixing with lower shear forces. Twin shaft mixers, while consuming more energy, offer faster mixing times and higher throughput, which can offset operational costs in high-volume or heavy-duty mixing processes. Choosing between the two depends on balancing energy efficiency with production speed and material characteristics to optimize overall cost-effectiveness.

Applications and Material Compatibility

Single shaft mixers are ideal for high-viscosity materials such as pastes, doughs, and heavy slurries, commonly used in industries like food processing, pharmaceuticals, and construction. Twin shaft mixers excel in handling a wide range of materials including granular, powdery, and semi-dry compounds, making them suitable for concrete production, chemical processing, and waste treatment. Material compatibility varies as single shaft mixers perform well with sticky or cohesive substances, while twin shaft mixers offer better mixing efficiency for free-flowing and dry materials.

Maintenance and Durability Comparison

Single shaft mixers typically offer easier maintenance due to their simpler design with fewer moving parts, resulting in reduced downtime and lower repair costs. Twin shaft mixers, while more complex, provide enhanced durability for heavy-duty applications by evenly distributing wear and handling higher loads, but require more frequent inspection and specialized maintenance. The choice between the two depends on the operational demands, with single shaft mixers favored for low to medium intensity use and twin shaft mixers for robust, continuous mixing needs.

Factors to Consider When Choosing a Mixer

When selecting between a single shaft mixer and a twin shaft mixer, consider factors such as mixing efficiency, batch size, and material characteristics. Single shaft mixers are ideal for smaller batches and materials requiring gentle mixing, while twin shaft mixers provide faster, more intensive mixing suitable for larger volumes and heavy-duty applications. Power consumption, maintenance requirements, and space availability also influence the optimal choice for specific industrial needs.

Conclusion: Which Mixer Fits Your Needs?

A Single Shaft Mixer is ideal for applications requiring gentle mixing and thorough homogeneity, making it suitable for dry powders and light materials with moderate batch sizes. Twin Shaft Mixers excel in heavy-duty mixing tasks, offering superior power and speed for high-viscosity materials, larger batches, and rapid processing times. Selecting between a Single Shaft and Twin Shaft Mixer depends on your material characteristics, production scale, and mixing speed requirements.

Single Shaft Mixer vs Twin Shaft Mixer Infographic

libmatt.com

libmatt.com