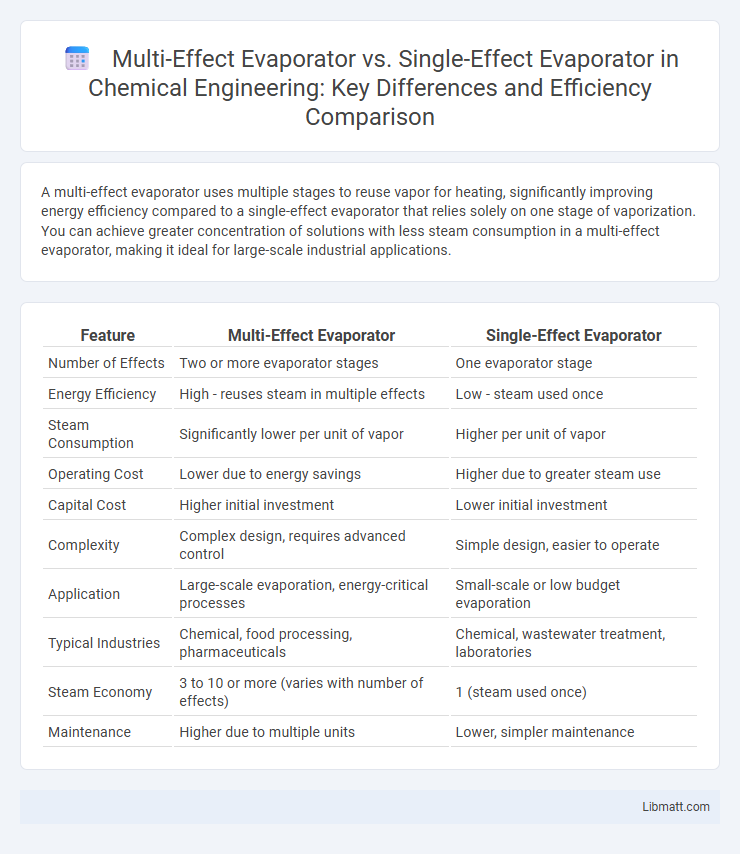

A multi-effect evaporator uses multiple stages to reuse vapor for heating, significantly improving energy efficiency compared to a single-effect evaporator that relies solely on one stage of vaporization. You can achieve greater concentration of solutions with less steam consumption in a multi-effect evaporator, making it ideal for large-scale industrial applications.

Table of Comparison

| Feature | Multi-Effect Evaporator | Single-Effect Evaporator |

|---|---|---|

| Number of Effects | Two or more evaporator stages | One evaporator stage |

| Energy Efficiency | High - reuses steam in multiple effects | Low - steam used once |

| Steam Consumption | Significantly lower per unit of vapor | Higher per unit of vapor |

| Operating Cost | Lower due to energy savings | Higher due to greater steam use |

| Capital Cost | Higher initial investment | Lower initial investment |

| Complexity | Complex design, requires advanced control | Simple design, easier to operate |

| Application | Large-scale evaporation, energy-critical processes | Small-scale or low budget evaporation |

| Typical Industries | Chemical, food processing, pharmaceuticals | Chemical, wastewater treatment, laboratories |

| Steam Economy | 3 to 10 or more (varies with number of effects) | 1 (steam used once) |

| Maintenance | Higher due to multiple units | Lower, simpler maintenance |

Introduction to Evaporators

Multi-effect evaporators increase efficiency by using steam multiple times across several stages, significantly reducing energy consumption compared to single-effect evaporators that operate with one stage and higher steam usage. Single-effect evaporators are simpler in design and lower in upfront cost but less energy-efficient for large-scale industrial processes. You can optimize production and reduce operational costs by selecting a multi-effect evaporator for applications requiring high volume and continuous evaporation.

What is a Single-Effect Evaporator?

A single-effect evaporator is an industrial device designed to concentrate solutions by evaporating solvent using one stage of heating, typically steam. It operates by boiling the liquid in a single vessel, where heat transfer causes solvent evaporation and subsequent vapor removal. This type of evaporator is energy-intensive compared to multi-effect evaporators, which reuse vapor to improve thermal efficiency.

What is a Multi-Effect Evaporator?

A Multi-Effect Evaporator is an advanced industrial device designed to efficiently concentrate solutions by using multiple stages or "effects" to evaporate water sequentially, thereby reducing energy consumption. Each effect operates at a lower pressure and temperature than the previous one, allowing the vapor from one stage to serve as the heating medium for the next. You can achieve significant energy savings and improved process efficiency by choosing a Multi-Effect Evaporator over a Single-Effect Evaporator, which relies on one stage and consumes more steam per unit of evaporated solvent.

Working Principle: Single vs Multi-Effect

Single-effect evaporators operate by boiling the liquid once, using a single heat source to convert the solvent into vapor at a specific temperature and pressure. Multi-effect evaporators utilize multiple stages where the vapor generated from one effect serves as the heating source for the next, significantly enhancing energy efficiency by reusing latent heat across several effects. This cascading principle in multi-effect systems reduces steam consumption compared to single-effect evaporators, making it ideal for large-scale industrial processes.

Energy Efficiency Comparison

Multi-effect evaporators significantly enhance energy efficiency by utilizing the vapor produced from one effect to heat the next, reducing overall steam consumption compared to single-effect evaporators. Your operation can achieve energy savings of up to 70% since single-effect evaporators rely solely on fresh steam for each evaporation stage. This efficient heat recycling makes multi-effect systems ideal for industries aiming to minimize energy costs and environmental impact.

Operational Cost Analysis

Multi-effect evaporators significantly reduce operational costs by utilizing the vapor generated in one effect as the heating medium for the next, resulting in lower steam consumption compared to single-effect evaporators. Single-effect evaporators require more steam and energy input per unit of water evaporated, leading to higher fuel and operational expenses. The improved energy efficiency of multi-effect evaporators directly translates into cost savings in industrial applications where large-scale evaporation is essential.

Space and Installation Requirements

Multi-effect evaporators require less installation space compared to single-effect evaporators due to their ability to reuse steam multiple times across several effects, enhancing energy efficiency and reducing the overall footprint. Single-effect evaporators demand larger installation areas since each unit operates independently, necessitating more extensive piping and heat exchange equipment. The compact design of multi-effect systems results in lower capital costs and easier integration into existing plant layouts.

Applications and Industrial Use Cases

Multi-effect evaporators are widely used in industries requiring high energy efficiency and large-scale volume reduction, such as sugar refining, desalination, and chemical manufacturing. Single-effect evaporators are preferred for smaller-scale operations or processes where lower capital investment and simpler design are sufficient, such as in pharmaceutical production and food processing. The choice between multi-effect and single-effect evaporators depends on factors like feed concentration, desired throughput, and energy availability.

Pros and Cons of Each System

Multi-effect evaporators offer higher energy efficiency by utilizing vapor from one effect as the heating medium for the next, significantly reducing steam consumption compared to single-effect evaporators. However, they involve higher initial capital costs and more complex maintenance due to multiple stages and equipment complexity. Single-effect evaporators are simpler, less expensive to install, and easier to operate but consume more steam per unit of evaporated liquid, resulting in higher operational costs.

Choosing the Right Evaporator for Your Process

Selecting the appropriate evaporator depends on factors like energy efficiency, operational cost, and the required concentration level; multi-effect evaporators offer significant energy savings by utilizing vapor from one effect as the heating medium for the next, thus reducing steam consumption. Single-effect evaporators, while simpler and less expensive to install, consume more steam and are suited for smaller-scale operations or processes with less stringent energy demands. Process characteristics such as feed composition, desired concentration, and budget constraints are critical in determining whether a multi-effect or single-effect evaporator aligns best with your operational goals.

Multi-effect evaporator vs single-effect evaporator Infographic

libmatt.com

libmatt.com