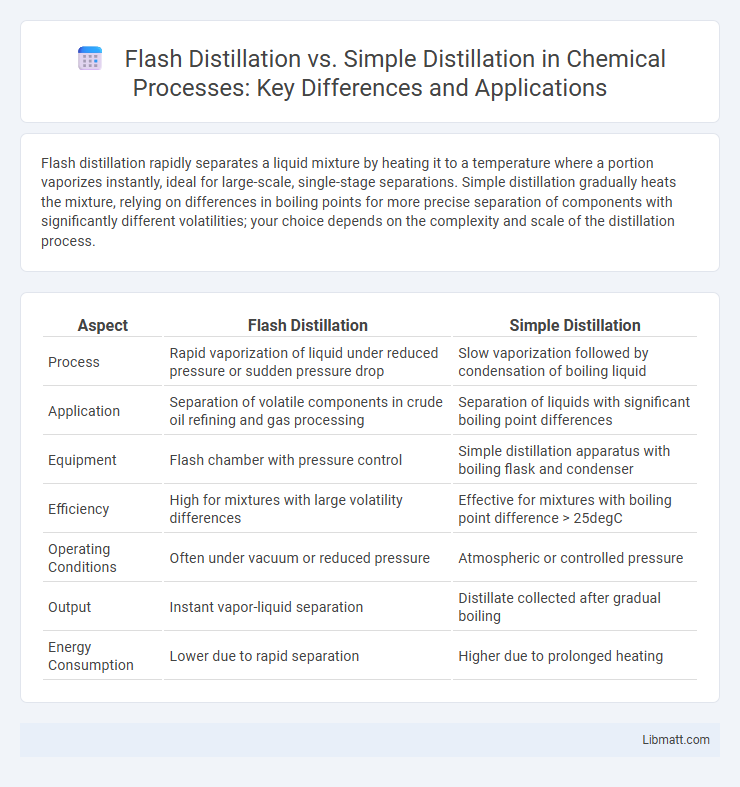

Flash distillation rapidly separates a liquid mixture by heating it to a temperature where a portion vaporizes instantly, ideal for large-scale, single-stage separations. Simple distillation gradually heats the mixture, relying on differences in boiling points for more precise separation of components with significantly different volatilities; your choice depends on the complexity and scale of the distillation process.

Table of Comparison

| Aspect | Flash Distillation | Simple Distillation |

|---|---|---|

| Process | Rapid vaporization of liquid under reduced pressure or sudden pressure drop | Slow vaporization followed by condensation of boiling liquid |

| Application | Separation of volatile components in crude oil refining and gas processing | Separation of liquids with significant boiling point differences |

| Equipment | Flash chamber with pressure control | Simple distillation apparatus with boiling flask and condenser |

| Efficiency | High for mixtures with large volatility differences | Effective for mixtures with boiling point difference > 25degC |

| Operating Conditions | Often under vacuum or reduced pressure | Atmospheric or controlled pressure |

| Output | Instant vapor-liquid separation | Distillate collected after gradual boiling |

| Energy Consumption | Lower due to rapid separation | Higher due to prolonged heating |

Introduction to Flash Distillation and Simple Distillation

Flash distillation involves rapid vaporization of a liquid mixture at reduced pressure, instantly separating components based on volatility differences, while simple distillation relies on gradual boiling and condensation to separate mixtures with significant boiling point differences. Your choice between flash and simple distillation depends on factors like mixture composition, desired purity, and operational efficiency. Flash distillation offers quicker separation for multi-component mixtures, whereas simple distillation is ideal for purifying liquids with large boiling point disparities.

Principles and Mechanisms of Simple Distillation

Simple distillation relies on the principle of separating liquids based on differences in boiling points, using heat to vaporize the more volatile component while leaving less volatile substances in the liquid phase. This process involves heating a liquid mixture until the component with the lower boiling point vaporizes, then condensing the vapor back into liquid form through a cooling system. Its mechanism depends on the careful control of temperature and vapor-liquid equilibrium to achieve an effective separation of components with significantly different volatilities.

Fundamentals of Flash Distillation Process

Flash distillation operates by rapidly vaporizing a liquid mixture at a pressure below its bubble point, causing a portion of the mixture to vaporize instantly upon a sudden pressure drop. This process relies on thermodynamic equilibrium between the vapor and liquid phases, allowing separation based on differences in component volatilities. Unlike simple distillation, flash distillation achieves partial vaporization in a single stage without continuous reflux or multiple theoretical plates.

Key Differences Between Flash and Simple Distillation

Flash distillation rapidly vaporizes a liquid mixture at reduced pressure to separate components with significant boiling point differences, while simple distillation relies on gradual heating and condensation of vapors at atmospheric pressure, making it suitable for purifying liquids with larger boiling point gaps. Flash distillation is often used in industrial applications for efficient separation of heat-sensitive or multi-component mixtures, whereas simple distillation is common in laboratory settings for basic purification tasks. The primary distinctions lie in operating pressure, vaporization rate, and the complexity of separation achievable.

Equipment Used in Flash vs. Simple Distillation

Flash distillation utilizes specialized equipment such as a flash drum or flash tank, where the liquid mixture is rapidly heated and partially vaporized under controlled pressure, allowing immediate separation of vapor and liquid phases. Simple distillation, in contrast, typically uses a distillation flask, a condenser, and a receiving flask, relying on gradual heating to separate components based on differences in boiling points. Your choice between flash and simple distillation equipment depends on the desired separation efficiency and the nature of the mixture being distilled.

Applications and Industrial Uses

Flash distillation is widely used in industrial processes where rapid separation of components with significantly different boiling points is required, such as in petroleum refining and chemical manufacturing. Simple distillation finds applications in laboratories and small-scale industries for purifying liquids or separating mixtures with large boiling point differences, like water purification and essential oil extraction. Your choice between these methods depends on factors like feed composition, desired product purity, and operational efficiency in specific industrial contexts.

Efficiency and Purity Comparison

Flash distillation achieves higher efficiency by rapidly vaporizing a portion of the liquid mixture, resulting in better separation with fewer stages compared to simple distillation, which relies on gradual vaporization and condensation cycles. The purity of the distillate in flash distillation is generally superior due to its ability to handle mixtures with close boiling points more effectively, whereas simple distillation often yields lower purity when components have similar volatilities. Flash distillation's continuous vapor-liquid equilibrium enhances overall separation performance, making it more suitable for industrial applications requiring higher throughput and product purity.

Energy Consumption and Operational Costs

Flash distillation requires significantly less energy compared to simple distillation due to its single-stage vaporization process, which reduces heating time and temperature requirements. This energy efficiency directly lowers operational costs by minimizing fuel and utility consumption. Simple distillation demands continuous heating and longer processing times, leading to higher energy inputs and increased expenses for equipment maintenance and operation.

Advantages and Limitations of Each Method

Flash distillation offers rapid separation by quickly vaporizing a liquid mixture at reduced pressure, making it energy-efficient and suitable for heat-sensitive components, but it requires precise control and may yield lower purity compared to other methods. Simple distillation is straightforward and ideal for separating liquids with significantly different boiling points, providing higher purity, yet it consumes more time and energy and is less effective for close-boiling mixtures. Your choice depends on the desired efficiency, purity, and complexity of the separation process.

Choosing the Right Distillation Method

Choosing the right distillation method depends on the desired purity and separation efficiency; flash distillation rapidly vaporizes a liquid mixture at reduced pressure, making it ideal for quick separation of components with significant boiling point differences. Simple distillation is better suited for separating mixtures with large boiling point gaps under atmospheric pressure, providing a straightforward and cost-effective approach for purifying liquids. Factors such as feed composition, thermal sensitivity, and equipment availability guide the selection between flash and simple distillation.

flash distillation vs simple distillation Infographic

libmatt.com

libmatt.com