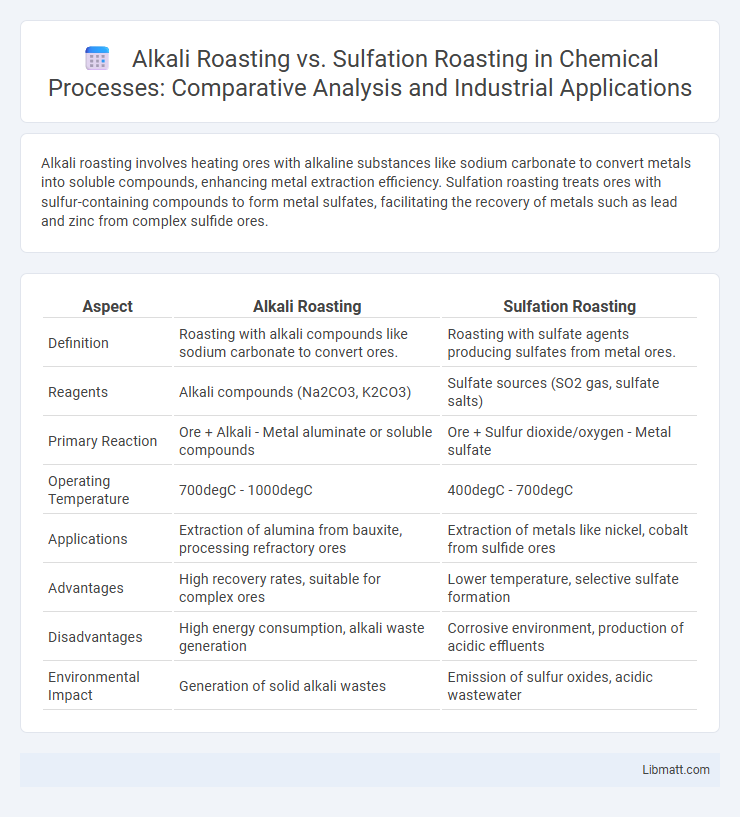

Alkali roasting involves heating ores with alkaline substances like sodium carbonate to convert metals into soluble compounds, enhancing metal extraction efficiency. Sulfation roasting treats ores with sulfur-containing compounds to form metal sulfates, facilitating the recovery of metals such as lead and zinc from complex sulfide ores.

Table of Comparison

| Aspect | Alkali Roasting | Sulfation Roasting |

|---|---|---|

| Definition | Roasting with alkali compounds like sodium carbonate to convert ores. | Roasting with sulfate agents producing sulfates from metal ores. |

| Reagents | Alkali compounds (Na2CO3, K2CO3) | Sulfate sources (SO2 gas, sulfate salts) |

| Primary Reaction | Ore + Alkali - Metal aluminate or soluble compounds | Ore + Sulfur dioxide/oxygen - Metal sulfate |

| Operating Temperature | 700degC - 1000degC | 400degC - 700degC |

| Applications | Extraction of alumina from bauxite, processing refractory ores | Extraction of metals like nickel, cobalt from sulfide ores |

| Advantages | High recovery rates, suitable for complex ores | Lower temperature, selective sulfate formation |

| Disadvantages | High energy consumption, alkali waste generation | Corrosive environment, production of acidic effluents |

| Environmental Impact | Generation of solid alkali wastes | Emission of sulfur oxides, acidic wastewater |

Introduction to Roasting Processes

Roasting processes transform sulfide and oxide ores into more concentrated or reactive forms for further extraction of metals. Alkali roasting involves heating ores with alkali compounds like sodium carbonate, enabling conversion of metal sulfides into water-soluble sulfates or oxides. Sulfation roasting, by contrast, oxidizes sulfide minerals at controlled temperatures to form stable metal sulfates, facilitating subsequent leaching and metal recovery.

Overview of Alkali Roasting

Alkali roasting involves heating ores with alkali compounds such as sodium carbonate or sodium hydroxide to convert metal sulfides into water-soluble metal salts, facilitating subsequent extraction processes. This method is particularly effective for treating complex sulfide ores and refractory materials, improving metal recovery rates while minimizing environmental pollution. Your choice of alkali roasting depends on the type of ore and desired metal, making it a critical step in hydrometallurgical operations.

Overview of Sulfation Roasting

Sulfation roasting involves heating sulfide ores in the presence of oxygen to convert metals into their sulfate forms, enhancing metal extraction efficiency during subsequent hydrometallurgical processing. This method is particularly effective for complex ores containing multiple valuable metals such as copper, nickel, and cobalt, as sulfates often exhibit higher solubility. Compared to alkali roasting, sulfation roasting operates under controlled temperature ranges to prevent the decomposition of sulfates and optimize metal recovery.

Key Chemical Reactions Involved

Alkali roasting involves the reaction of ores with alkaline compounds such as sodium carbonate or sodium hydroxide, converting metal sulfides into water-soluble metal oxides or sodium salts, facilitating easier extraction. In sulfation roasting, metal sulfide ores react with oxygen at elevated temperatures to form metal sulfates, enhancing metal recovery through subsequent leaching. You can optimize metal extraction by understanding these key chemical reactions, which dictate the choice of roasting method based on ore composition and desired outcomes.

Temperature and Process Conditions

Alkali roasting typically occurs at temperatures between 600degC and 900degC, involving the reaction of ores with alkali compounds such as sodium carbonate, which facilitates the conversion of metal oxides into soluble forms for subsequent leaching. Sulfation roasting is generally conducted at lower temperatures ranging from 400degC to 700degC, where the ore is heated in the presence of sulfur dioxide or sulfate salts to form metal sulfates that enhance metal recovery. The choice of roasting method depends on ore composition and desired chemical transformations, with alkali roasting favoring alkaline conditions and higher temperatures, while sulfation roasting operates under milder temperatures and sulfur-rich atmospheres.

Metal Extraction Efficiency

Alkali roasting enhances metal extraction efficiency by converting refractory metals into soluble sodium compounds, facilitating easier leaching and higher recovery rates compared to sulfation roasting. Sulfation roasting primarily forms metal sulfates, which may suffer from incomplete conversion and lower solubility, limiting the overall extraction yield. Your choice between these methods should consider the specific ore composition and desired metal recovery efficiency.

Environmental Impact Comparison

Alkali roasting generates fewer hazardous gases compared to sulfation roasting, which releases significant amounts of sulfur dioxide, contributing to acid rain and air pollution. The solid waste from alkali roasting is often more stable and easier to manage, reducing soil and water contamination risks relative to the acidic residues produced in sulfation roasting. Overall, alkali roasting presents a more environmentally favorable profile due to lower emissions and safer byproducts.

Applications in Metallurgical Industries

Alkali roasting and sulfation roasting serve distinct roles in metallurgical industries, with alkali roasting primarily used for treating refractory ores containing metals like tin and tungsten by converting them into water-soluble compounds. Sulfation roasting is favored for extracting valuable metals such as copper, nickel, and cobalt from sulfide ores by transforming metal sulfides into metal sulfates, facilitating easier metal recovery. Understanding these processes enhances Your ability to select the appropriate roasting technique for efficient metal extraction during ore processing.

Advantages and Limitations

Alkali roasting offers advantages such as lower roasting temperatures and effective removal of silica impurities, enhancing metal recovery from complex ores, but it faces limitations including high reagent consumption and the generation of alkaline wastewater that requires treatment. Sulfation roasting enables selective conversion of metal sulfides to soluble sulfates, facilitating efficient leaching, with advantages including better recovery of metals like copper and molybdenum; however, it is limited by the production of sulfur dioxide gas, necessitating gas scrubbing systems and posing environmental concerns. Both methods present trade-offs in operational costs, environmental impact, and suitability for specific ore types, influencing their industrial applicability.

Conclusion and Future Perspectives

Alkali roasting offers efficient extraction of valuable metals from complex ores with lower environmental impact, whereas sulfation roasting excels in producing sulfate compounds suitable for further hydrometallurgical processing. Future perspectives emphasize integrating these methods with advanced bioleaching and recycling technologies to enhance sustainability and resource recovery. Your choice of roasting technique should consider ore composition, processing goals, and environmental regulations to optimize metal yield and minimize ecological footprint.

Alkali roasting vs sulfation roasting Infographic

libmatt.com

libmatt.com