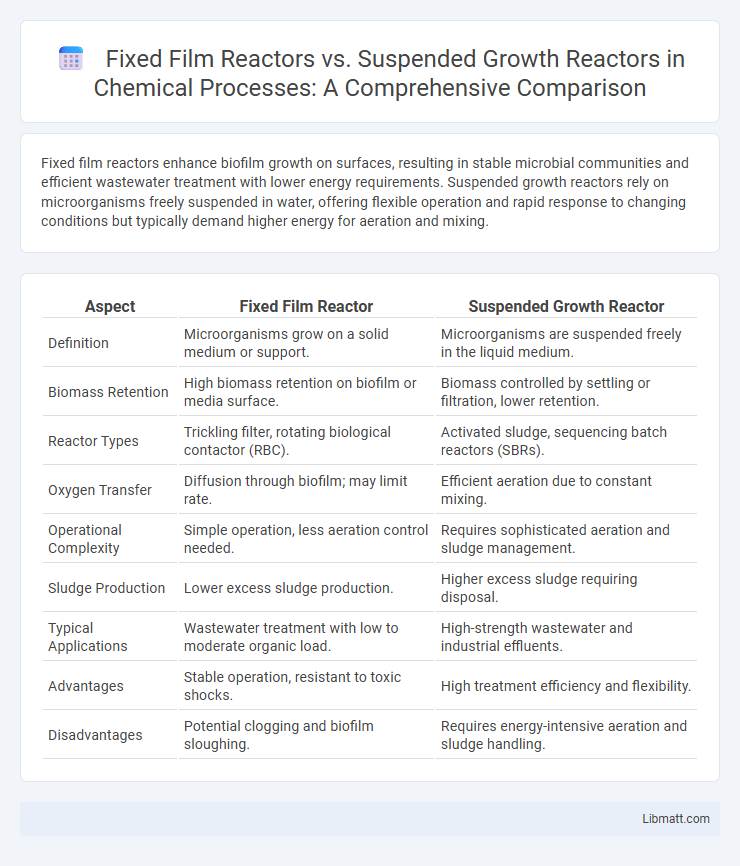

Fixed film reactors enhance biofilm growth on surfaces, resulting in stable microbial communities and efficient wastewater treatment with lower energy requirements. Suspended growth reactors rely on microorganisms freely suspended in water, offering flexible operation and rapid response to changing conditions but typically demand higher energy for aeration and mixing.

Table of Comparison

| Aspect | Fixed Film Reactor | Suspended Growth Reactor |

|---|---|---|

| Definition | Microorganisms grow on a solid medium or support. | Microorganisms are suspended freely in the liquid medium. |

| Biomass Retention | High biomass retention on biofilm or media surface. | Biomass controlled by settling or filtration, lower retention. |

| Reactor Types | Trickling filter, rotating biological contactor (RBC). | Activated sludge, sequencing batch reactors (SBRs). |

| Oxygen Transfer | Diffusion through biofilm; may limit rate. | Efficient aeration due to constant mixing. |

| Operational Complexity | Simple operation, less aeration control needed. | Requires sophisticated aeration and sludge management. |

| Sludge Production | Lower excess sludge production. | Higher excess sludge requiring disposal. |

| Typical Applications | Wastewater treatment with low to moderate organic load. | High-strength wastewater and industrial effluents. |

| Advantages | Stable operation, resistant to toxic shocks. | High treatment efficiency and flexibility. |

| Disadvantages | Potential clogging and biofilm sloughing. | Requires energy-intensive aeration and sludge handling. |

Introduction to Biological Wastewater Treatment

Fixed film reactors and suspended growth reactors are two prevalent biological wastewater treatment technologies that utilize microorganisms to degrade organic pollutants. Fixed film reactors employ a biofilm attached to a medium, providing a stable environment for microbial growth and efficient treatment in limited space, while suspended growth reactors maintain microorganisms in suspension, promoting high reaction rates and flexibility in handling varying loads. Your choice depends on factors like space availability, wastewater characteristics, and desired treatment goals, with fixed film systems often preferred for lower energy consumption and suspended growth reactors favored for high-strength or variable wastewater.

Overview of Fixed Film Reactors

Fixed film reactors utilize biofilms attached to surfaces where microorganisms grow and treat wastewater, enhancing biomass retention and treatment efficiency compared to suspended growth reactors. These systems support higher microbial concentrations and improved resistance to toxic shocks, making them ideal for treating high-strength or variable wastewater streams. Common types include trickling filters, rotating biological contactors, and packed bed reactors, each designed to maximize surface area for microbial growth and oxygen transfer.

Overview of Suspended Growth Reactors

Suspended growth reactors maintain microorganisms in a mixed liquid phase, allowing them to treat wastewater efficiently by breaking down organic contaminants. These reactors rely on aeration and continuous mixing to keep biomass suspended, promoting high oxygen transfer and nutrient availability. Common types include activated sludge systems, which are widely used due to their scalability and effective removal of biochemical oxygen demand (BOD) and ammonia.

Key Design Differences

Fixed film reactors utilize a stationary biofilm attached to a support medium, promoting microbial growth on surfaces, whereas suspended growth reactors maintain microorganisms suspended in the liquid phase. The design of fixed film reactors emphasizes maximizing surface area for biofilm development, often involving media like plastic carriers or porous materials, while suspended growth reactors rely on aeration and mixing to keep biomass evenly distributed. Your choice between these reactors impacts operational parameters such as retention time, oxygen transfer efficiency, and system maintenance requirements.

Process Mechanisms Comparison

Fixed film reactors rely on biofilms attached to media surfaces, enabling microorganisms to degrade pollutants through continuous substrate contact and stable biomass retention. Suspended growth reactors utilize freely suspended microbial cells in the mixed liquid phase, promoting rapid substrate interaction but requiring higher energy for mixing and aeration. The fixed film system offers enhanced resistance to shock loads and variable influent, while suspended growth reactors provide greater flexibility in biomass concentration and operational control.

Performance and Efficiency

Fixed film reactors offer higher biomass retention and enhanced treatment efficiency due to the biofilm's stability on surfaces, enabling consistent pollutant degradation even under fluctuating loads. Suspended growth reactors rely on biomass suspended in the liquid, which can result in faster response times but may require more energy for mixing and aeration, potentially reducing overall energy efficiency. Your choice depends on balancing operational costs with desired treatment performance, as fixed film systems typically achieve superior organic removal and nutrient recovery efficiency.

Advantages of Fixed Film Reactors

Fixed film reactors offer higher biomass retention, enabling more efficient treatment of high-strength wastewater compared to suspended growth reactors. They provide greater resistance to shock loads and variable organic loading rates, ensuring consistent performance and reduced sludge production. Your wastewater treatment process benefits from lower operational costs and improved system stability with fixed film reactor technology.

Advantages of Suspended Growth Reactors

Suspended growth reactors offer enhanced microbial contact with wastewater, improving treatment efficiency and reducing sludge production compared to fixed film reactors. Their operational flexibility allows for easy adjustments to load variations and simpler maintenance without the need for complex media support structures. You benefit from faster startup times and better biomass control, making suspended growth systems ideal for variable wastewater conditions.

Applications and Suitability

Fixed film reactors excel in wastewater treatment applications requiring high biomass retention and stability, such as nitrification and industrial effluent processing, due to their attached microbial communities. Suspended growth reactors are better suited for treating municipal wastewater with variable loads, offering flexibility and ease of control through mixed microbial populations in suspension. Selection depends on wastewater characteristics, treatment goals, and operational considerations like space availability and maintenance.

Conclusion and Recommendations

Fixed film reactors offer higher biomass retention and better resistance to shock loads, making them suitable for wastewater with fluctuating organic loads. Suspended growth reactors provide greater flexibility in controlling microbial populations and are easier to scale for varying treatment capacities. You should choose a fixed film reactor for stable, high-strength wastewaters and a suspended growth reactor for applications requiring operational flexibility and easier maintenance.

fixed film reactor vs suspended growth reactor Infographic

libmatt.com

libmatt.com