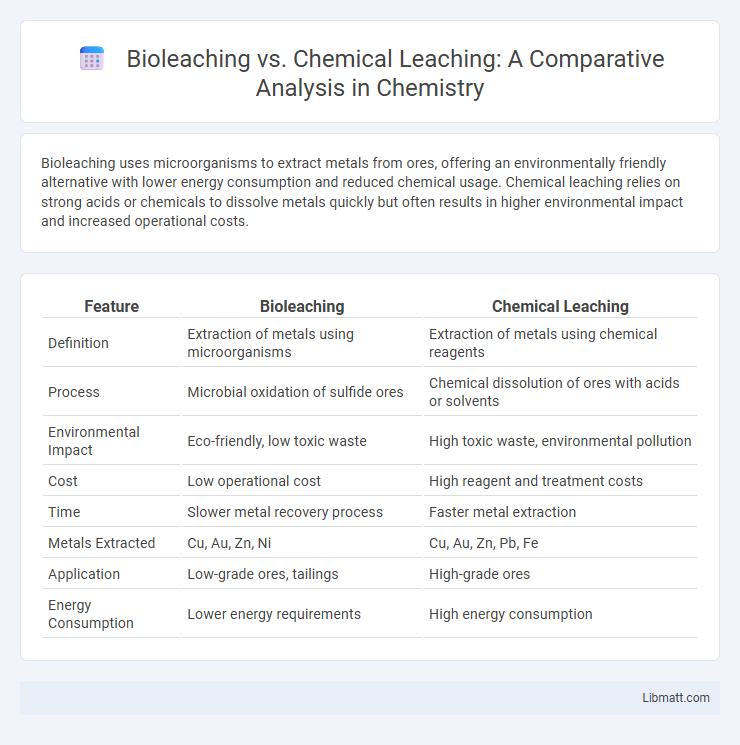

Bioleaching uses microorganisms to extract metals from ores, offering an environmentally friendly alternative with lower energy consumption and reduced chemical usage. Chemical leaching relies on strong acids or chemicals to dissolve metals quickly but often results in higher environmental impact and increased operational costs.

Table of Comparison

| Feature | Bioleaching | Chemical Leaching |

|---|---|---|

| Definition | Extraction of metals using microorganisms | Extraction of metals using chemical reagents |

| Process | Microbial oxidation of sulfide ores | Chemical dissolution of ores with acids or solvents |

| Environmental Impact | Eco-friendly, low toxic waste | High toxic waste, environmental pollution |

| Cost | Low operational cost | High reagent and treatment costs |

| Time | Slower metal recovery process | Faster metal extraction |

| Metals Extracted | Cu, Au, Zn, Ni | Cu, Au, Zn, Pb, Fe |

| Application | Low-grade ores, tailings | High-grade ores |

| Energy Consumption | Lower energy requirements | High energy consumption |

Introduction to Bioleaching and Chemical Leaching

Bioleaching harnesses microorganisms such as Acidithiobacillus ferrooxidans to extract metals from ores by biologically oxidizing sulfide minerals, offering an eco-friendly alternative to traditional methods. Chemical leaching employs reagents like cyanide or sulfuric acid to chemically dissolve metals from ores, enabling rapid extraction but often posing environmental risks due to toxic waste generation. Both techniques are pivotal in mining industries for metal recovery, with bioleaching emphasizing sustainability and chemical leaching prioritizing efficiency.

Principles and Mechanisms of Bioleaching

Bioleaching utilizes microorganisms to catalyze the breakdown of metal sulfides, converting insoluble metal compounds into soluble forms through biological oxidation. These microbes, such as Acidithiobacillus ferrooxidans, oxidize iron and sulfur compounds in ores, facilitating metal extraction in an environmentally friendly manner. Your choice between bioleaching and chemical leaching depends on the ore type and environmental considerations, as chemical leaching relies on inorganic reagents that may generate hazardous waste.

Chemical Leaching: Methods and Reactions

Chemical leaching involves extracting metals from ores using acid or alkaline solutions, with common methods including heap leaching, tank leaching, and in-situ leaching. Typical reactions depend on the metal and lixiviant used; for example, sulfuric acid dissolves copper sulfides through the oxidation of chalcopyrite (CuFeS2) into soluble copper sulfate. Understanding these specific methods and reactions helps you optimize metal recovery efficiently in mineral processing operations.

Key Microorganisms in Bioleaching Processes

Bioleaching relies on key microorganisms such as Acidithiobacillus ferrooxidans, Leptospirillum ferrooxidans, and Sulfobacillus species, which facilitate the extraction of metals by oxidizing sulfide minerals. Chemical leaching, in contrast, employs inorganic chemicals like cyanide or sulfuric acid without microbial involvement, resulting in faster but sometimes environmentally harmful metal recovery. Understanding the role of these specialized bioleaching microbes can optimize Your metal extraction processes by enhancing efficiency and reducing ecological impact.

Advantages of Bioleaching Over Chemical Leaching

Bioleaching offers eco-friendly metal extraction by using microorganisms to break down ores, significantly reducing toxic chemical waste compared to chemical leaching. This method lowers environmental contamination risks and energy consumption, making it safer for surrounding ecosystems. You benefit from bioleaching's cost-effectiveness and sustainability, especially in processing low-grade ores where chemical leaching is less efficient.

Environmental Impacts: Bioleaching vs Chemical Leaching

Bioleaching leverages microorganisms to extract metals from ores, resulting in lower toxic emissions and reduced chemical waste compared to chemical leaching, which often involves harsh acids like sulfuric acid leading to soil and water contamination. The biodegradability of bioleaching agents minimizes long-term environmental damage, whereas chemical leaching generates hazardous byproducts that require extensive treatment to prevent ecological harm. Bioleaching's sustainable nature makes it preferable for metal recovery in ecologically sensitive areas, promoting reduced carbon footprint and enhanced biodegradability over conventional chemical methods.

Efficiency and Yield Comparison

Bioleaching offers higher efficiency in extracting metals from low-grade ores due to its environmentally friendly microbial processes, resulting in better yield retention and reduced energy consumption compared to chemical leaching. Chemical leaching may achieve faster metal recovery rates but often involves harsher reagents that can lead to metal losses and environmental concerns, lowering overall yield efficiency. Your choice between bioleaching and chemical leaching should consider the ore type and environmental impact to maximize extraction yield and operational efficiency.

Industrial Applications and Case Studies

Bioleaching has been successfully applied in the extraction of copper from low-grade ores in large-scale mining operations such as Escondida in Chile and the Bingham Canyon Mine in the USA. Chemical leaching remains prevalent in industries requiring rapid metal recovery, including gold extraction through cyanide leaching at the Yanacocha mine in Peru. Case studies highlight bioleaching's environmental advantages and cost-efficiency in treating sulfide ores, while chemical leaching is favored for its speed and effectiveness in high-grade ore processing.

Challenges and Limitations of Both Methods

Bioleaching faces challenges such as longer processing times, sensitivity to environmental conditions, and limited effectiveness on low-grade ores. Chemical leaching involves risks like toxic reagent usage, higher operational costs, and environmental hazards due to chemical waste disposal. Your choice between these methods should consider the mine's ore type, environmental regulations, and economic feasibility.

Future Trends in Leaching Technologies

Future trends in leaching technologies emphasize eco-friendly bioleaching methods that use microorganisms to extract metals, reducing environmental impact compared to traditional chemical leaching. Advancements in genetic engineering are expected to enhance microbial efficiency and metal recovery rates, making bioleaching a more viable alternative for complex ores. Your choice of leaching technology will increasingly depend on sustainability goals and the economic feasibility of integrating these innovative biological processes.

Bioleaching vs chemical leaching Infographic

libmatt.com

libmatt.com