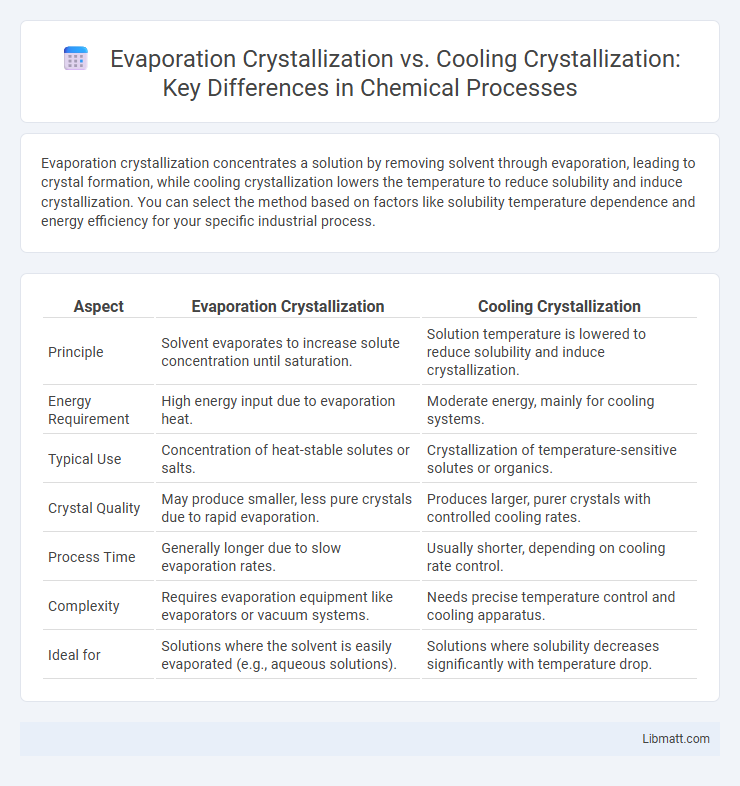

Evaporation crystallization concentrates a solution by removing solvent through evaporation, leading to crystal formation, while cooling crystallization lowers the temperature to reduce solubility and induce crystallization. You can select the method based on factors like solubility temperature dependence and energy efficiency for your specific industrial process.

Table of Comparison

| Aspect | Evaporation Crystallization | Cooling Crystallization |

|---|---|---|

| Principle | Solvent evaporates to increase solute concentration until saturation. | Solution temperature is lowered to reduce solubility and induce crystallization. |

| Energy Requirement | High energy input due to evaporation heat. | Moderate energy, mainly for cooling systems. |

| Typical Use | Concentration of heat-stable solutes or salts. | Crystallization of temperature-sensitive solutes or organics. |

| Crystal Quality | May produce smaller, less pure crystals due to rapid evaporation. | Produces larger, purer crystals with controlled cooling rates. |

| Process Time | Generally longer due to slow evaporation rates. | Usually shorter, depending on cooling rate control. |

| Complexity | Requires evaporation equipment like evaporators or vacuum systems. | Needs precise temperature control and cooling apparatus. |

| Ideal for | Solutions where the solvent is easily evaporated (e.g., aqueous solutions). | Solutions where solubility decreases significantly with temperature drop. |

Introduction to Crystallization Methods

Evaporation crystallization concentrates a solution by removing solvent through evaporation, promoting crystal formation as solute supersaturation increases. Cooling crystallization induces solute crystallization by lowering the solution temperature, which decreases solubility and triggers nucleation. Your choice between these methods depends on factors like solute solubility, process scalability, and energy efficiency.

Overview of Evaporation Crystallization

Evaporation crystallization is a separation process where solvent is removed by evaporation to supersaturate the solution, leading to crystal formation of the solute. This method is energy-intensive but highly effective for solutions with low solubility and allows precise control over crystal size and purity. Unlike cooling crystallization, which relies on temperature reduction, evaporation crystallization focuses on concentrating the solution by solvent removal to induce crystallization.

Overview of Cooling Crystallization

Cooling crystallization involves reducing the temperature of a supersaturated solution to induce the formation of solid crystals, a process commonly used in chemical and pharmaceutical industries for purifying compounds. It allows precise control over crystal size and purity by adjusting cooling rates and solution concentrations, enhancing product quality. Your choice of cooling crystallization can optimize yield and reduce energy consumption compared to evaporation crystallization.

Key Differences between Evaporation and Cooling Crystallization

Evaporation crystallization relies on the removal of solvent through vaporization to achieve supersaturation, whereas cooling crystallization reduces temperature to achieve the same effect. The rate of crystal growth in evaporation crystallization is generally slower due to gradual solvent removal, resulting in larger, purer crystals, while cooling crystallization often produces smaller crystals with faster nucleation. Energy consumption is typically higher in evaporation crystallization because of the heat required for vaporization compared to the lower thermal input needed for cooling crystallization.

Process Mechanisms and Principles

Evaporation crystallization involves concentrating a solution by removing solvent through heat-induced evaporation until supersaturation is achieved, leading to crystal nucleation and growth. Cooling crystallization relies on lowering the temperature of a solution to reduce solubility, causing solute molecules to come out of solution and form crystals. Both processes aim to control crystal size and purity by manipulating solubility dynamics, but evaporation uses phase change and solvent removal, while cooling adjusts thermal conditions to induce crystallization.

Advantages of Evaporation Crystallization

Evaporation crystallization offers higher purity crystals and better control over crystal size compared to cooling crystallization, making it ideal for sensitive applications in pharmaceuticals and fine chemicals. This method efficiently handles solutions that are difficult to supercool, reducing risks of unwanted nucleation, and allowing continuous operation for large-scale production. Your process benefits from improved yield and energy efficiency, especially when dealing with heat-stable compounds or high-boiling solvents.

Advantages of Cooling Crystallization

Cooling crystallization offers energy savings by utilizing temperature reduction rather than heat input, which lowers operational costs. This method enhances crystal purity and size uniformity due to controlled supersaturation levels achieved through cooling. It also provides better scalability and easier process control compared to evaporation crystallization, making it ideal for sensitive compounds.

Industrial Applications and Suitability

Evaporation crystallization is widely used in industries requiring high purity crystals and handling of heat-sensitive materials, such as pharmaceuticals, salt production, and sugar refining, due to its ability to concentrate solutions by removing solvent under controlled temperature. Cooling crystallization suits applications where solubility significantly decreases with temperature, making it ideal for producing fine, uniform crystals in industries like chemical manufacturing and food processing. Your choice between these methods depends on factors like thermal sensitivity, desired crystal size, and operational efficiency in your specific industrial process.

Factors Influencing Choice of Method

The choice between evaporation crystallization and cooling crystallization primarily depends on solute solubility, thermal stability, and desired crystal size. Evaporation crystallization is favored when solubility changes minimally with temperature or for heat-stable compounds, while cooling crystallization suits temperature-sensitive materials and those with high solubility variation. Your process requirements, such as energy consumption and purity levels, also influence the optimal crystallization technique selection.

Summary and Future Trends in Crystallization Technologies

Evaporation crystallization and cooling crystallization are pivotal techniques in the production of high-purity crystals, with evaporation focusing on solvent removal through heat and cooling crystallization relying on temperature reduction to induce crystal formation. Future trends highlight advancements in process intensification, energy efficiency, and the integration of real-time monitoring systems to optimize crystal size distribution and purity. Your selection between these methods should consider the specific material properties and scalability requirements to maximize yield and sustainability in industrial applications.

Evaporation crystallization vs cooling crystallization Infographic

libmatt.com

libmatt.com