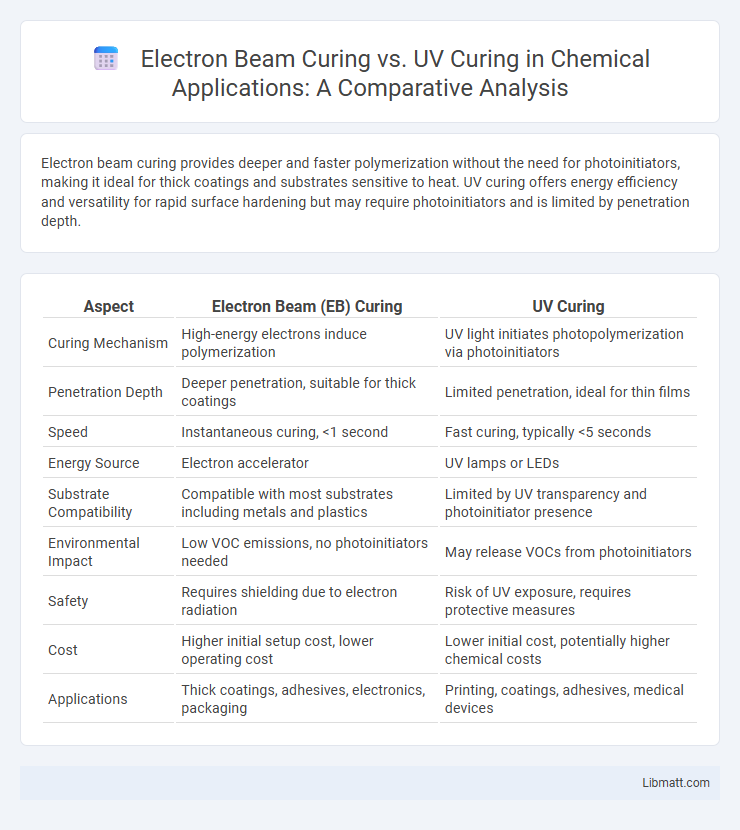

Electron beam curing provides deeper and faster polymerization without the need for photoinitiators, making it ideal for thick coatings and substrates sensitive to heat. UV curing offers energy efficiency and versatility for rapid surface hardening but may require photoinitiators and is limited by penetration depth.

Table of Comparison

| Aspect | Electron Beam (EB) Curing | UV Curing |

|---|---|---|

| Curing Mechanism | High-energy electrons induce polymerization | UV light initiates photopolymerization via photoinitiators |

| Penetration Depth | Deeper penetration, suitable for thick coatings | Limited penetration, ideal for thin films |

| Speed | Instantaneous curing, <1 second | Fast curing, typically <5 seconds |

| Energy Source | Electron accelerator | UV lamps or LEDs |

| Substrate Compatibility | Compatible with most substrates including metals and plastics | Limited by UV transparency and photoinitiator presence |

| Environmental Impact | Low VOC emissions, no photoinitiators needed | May release VOCs from photoinitiators |

| Safety | Requires shielding due to electron radiation | Risk of UV exposure, requires protective measures |

| Cost | Higher initial setup cost, lower operating cost | Lower initial cost, potentially higher chemical costs |

| Applications | Thick coatings, adhesives, electronics, packaging | Printing, coatings, adhesives, medical devices |

Introduction to Electron Beam and UV Curing

Electron beam curing uses high-energy electrons to initiate polymerization, enabling rapid curing of coatings, inks, and adhesives without photoinitiators. UV curing relies on ultraviolet light to activate photoinitiators in formulations, triggering fast cross-linking reactions essential for durable surface finishes. Electron beam curing offers deeper penetration and fewer restrictions on material thickness compared to UV curing, which excels in energy efficiency and cost-effectiveness for thin-film applications.

Core Principles of Electron Beam Curing

Electron beam curing utilizes high-energy electrons to initiate polymerization without the need for photoinitiators, penetrating deeply into coatings for rapid and thorough curing. This process improves adhesion and chemical resistance while reducing VOC emissions, making it ideal for thick or densely pigmented materials. Your production efficiency can significantly increase as electron beam curing enables instant curing even on heat-sensitive substrates.

Fundamentals of UV Curing Technology

UV curing technology relies on photoinitiators that absorb ultraviolet light to initiate polymerization, rapidly transforming liquid coatings into solid films. The process is energy-efficient and allows precise control over curing depth and speed, enhancing production throughput in various industries. Compared to electron beam curing, UV curing requires specifically formulated materials sensitive to UV wavelengths but offers benefits like lower equipment costs and simpler safety measures.

Process Comparison: Electron Beam vs UV Curing

Electron beam (EB) curing utilizes high-energy electrons to initiate polymerization without requiring photoinitiators, enabling faster curing times and deeper penetration compared to UV curing. UV curing relies on ultraviolet light to activate photoinitiators in coatings or inks, often limited by oxygen inhibition and substrate transparency. EB curing offers improved adhesion and durability on diverse materials, while UV curing remains cost-effective and widely used for applications needing surface-level curing.

Material Compatibility and Application Scope

Electron beam curing offers superior material compatibility, effectively curing a broader range of substrates including thick, pigmented, and opaque materials that UV curing often struggles with due to limited light penetration. This method excels in applications involving metals, ceramics, and complex composites, whereas UV curing is typically confined to thin, transparent, or lightly pigmented coatings and adhesives. The deeper and more uniform curing profile of electron beam technology expands its application scope to high-performance industries such as aerospace, automotive, and electronics manufacturing.

Energy Efficiency and Operational Costs

Electron beam curing offers higher energy efficiency by directly initiating polymerization without the need for photoinitiators, reducing overall power consumption compared to UV curing. This process lowers operational costs through faster curing times and minimal heat generation, decreasing cooling requirements and extending equipment lifespan. Your choice of electron beam curing can result in significant savings and improved sustainability in industrial applications.

Safety Considerations for Each Method

Electron beam curing reduces the risk of harmful ultraviolet exposure, enhancing operator safety by eliminating UV radiation hazards. UV curing requires strict controls to prevent skin and eye damage due to intense UV light, necessitating protective gear and shielding. Both methods demand proper ventilation to manage potential ozone and volatile organic compound emissions, ensuring safe working environments.

Environmental Impact and Regulatory Compliance

Electron beam curing produces fewer volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) compared to UV curing, significantly reducing environmental impact. It requires no photoinitiators, lowering chemical waste and improving worker safety, which aligns with stringent regulatory standards like EPA and REACH. UV curing, while energy-efficient, often involves chemical additives subject to stricter regulations and potential disposal challenges, making electron beam a more sustainable and compliant technology.

Industry Applications and Case Studies

Electron beam curing excels in heavy-duty industrial applications like automotive coatings and aerospace composites due to its deep penetration and rapid curing capabilities. UV curing is widely used in printing, electronics, and medical device manufacturing for its surface-level precision and ease of integration into existing production lines. Your choice between these technologies depends on factors such as substrate material, desired curing speed, and environmental considerations demonstrated in numerous case studies across diverse industries.

Choosing the Right Curing Technology

Electron beam curing offers faster processing speeds and deeper penetration compared to UV curing, making it ideal for thick or pigmented coatings. UV curing provides greater control over curing parameters and is cost-effective for surface coatings and thin films. Your choice should consider substrate compatibility, desired cure speed, and production scale to optimize efficiency and finish quality.

electron beam curing vs UV curing Infographic

libmatt.com

libmatt.com