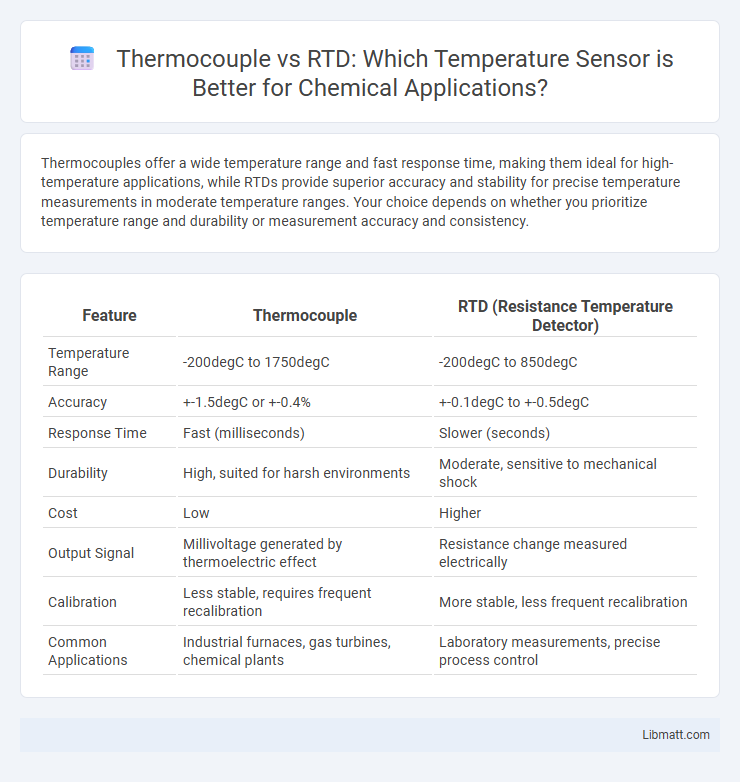

Thermocouples offer a wide temperature range and fast response time, making them ideal for high-temperature applications, while RTDs provide superior accuracy and stability for precise temperature measurements in moderate temperature ranges. Your choice depends on whether you prioritize temperature range and durability or measurement accuracy and consistency.

Table of Comparison

| Feature | Thermocouple | RTD (Resistance Temperature Detector) |

|---|---|---|

| Temperature Range | -200degC to 1750degC | -200degC to 850degC |

| Accuracy | +-1.5degC or +-0.4% | +-0.1degC to +-0.5degC |

| Response Time | Fast (milliseconds) | Slower (seconds) |

| Durability | High, suited for harsh environments | Moderate, sensitive to mechanical shock |

| Cost | Low | Higher |

| Output Signal | Millivoltage generated by thermoelectric effect | Resistance change measured electrically |

| Calibration | Less stable, requires frequent recalibration | More stable, less frequent recalibration |

| Common Applications | Industrial furnaces, gas turbines, chemical plants | Laboratory measurements, precise process control |

Introduction to Temperature Sensors

Thermocouples and RTDs are essential temperature sensors used in industrial and scientific applications. Thermocouples measure temperature based on voltage generated at the junction of two different metals, offering a wide temperature range and fast response. RTDs provide highly accurate temperature readings by measuring the resistance of a metal, typically platinum, making them ideal for precise and stable temperature monitoring in calibration and control systems.

What is a Thermocouple?

A thermocouple is a temperature sensor consisting of two different metal wires joined at one end, generating a voltage proportional to the temperature difference between the junction and the other ends. This voltage output allows precise temperature measurement across a wide range, often from -200degC to 1750degC, suitable for industrial applications requiring rapid response times. You can rely on thermocouples for accurate monitoring in harsh environments due to their durability and broad temperature tolerance.

What is an RTD (Resistance Temperature Detector)?

An RTD (Resistance Temperature Detector) is a precise temperature sensor that measures temperature by correlating the resistance of a metal element, typically platinum, with temperature changes. RTDs offer high accuracy, stability, and repeatability, making them ideal for applications requiring precise temperature monitoring. Your choice of RTD ensures reliable performance across a wide temperature range, especially in industrial and laboratory settings.

Thermocouple Working Principle

A thermocouple operates based on the Seebeck effect, where a voltage is generated at the junction of two different metals when exposed to a temperature gradient. This voltage correlates directly with temperature, allowing precise measurement across a wide range of temperatures. Thermocouples offer fast response times and are suitable for extreme environments due to their robust design and simple construction.

RTD Working Principle

RTD (Resistance Temperature Detector) operates based on the principle that the electrical resistance of metals changes predictably with temperature variations. It typically uses pure platinum due to its stable and repeatable resistance-temperature relationship, providing high accuracy for temperature measurement. When you use an RTD, temperature is determined by measuring the resistance of the platinum wire, which increases linearly as temperature rises.

Accuracy and Precision: Thermocouple vs RTD

RTDs (Resistance Temperature Detectors) offer higher accuracy and better precision than thermocouples, typically providing measurement accuracy within +-0.1degC compared to thermocouples' +-1.5degC. RTDs maintain stable resistance-temperature relationships over time, resulting in consistent and repeatable readings crucial for applications requiring precise temperature control. Thermocouples, while less accurate, excel in measuring extreme temperatures and fast response times but with greater variability and drift under prolonged use.

Temperature Range Comparison

Thermocouples operate effectively over a wide temperature range, typically from -200degC to 1750degC, making them suitable for extreme environments such as furnaces and gas turbines. RTDs (Resistance Temperature Detectors) generally cover a narrower range, from -200degC to 850degC, offering superior accuracy and stability within this mid-range spectrum. Your choice depends on the temperature range requirements of your application, with thermocouples favored for high-temperature measurements and RTDs preferred for precise readings at moderate temperatures.

Response Time Differences

Thermocouples typically exhibit faster response times, often within milliseconds to a few seconds, due to their small junction size and direct temperature measurement. RTDs generally have slower response times, ranging from several seconds to minutes, as their sensing elements require more thermal mass to stabilize. The faster response of thermocouples makes them ideal for applications requiring quick temperature changes detection, while RTDs provide more stable and accurate readings for steady-state conditions.

Application Areas: Thermocouple vs RTD

Thermocouples are widely used in high-temperature applications such as furnaces, gas turbines, and industrial processes due to their durability and fast response time. RTDs (Resistance Temperature Detectors) are preferred in laboratory, food processing, and HVAC systems where precise and stable temperature measurements are critical. Your choice depends on the temperature range, required accuracy, and environmental conditions of the application area.

Choosing the Right Temperature Sensor

Choosing the right temperature sensor depends on the specific application requirements, with thermocouples offering a wide temperature range and fast response ideal for high-temperature processes, while RTDs provide superior accuracy and stability in lower temperature environments. Thermocouples are cost-effective and suitable for harsh conditions, but RTDs deliver consistent and precise measurements, making them preferable for critical temperature control. Understanding your measurement needs, including temperature range, accuracy, response time, and environment, will guide you in selecting the optimal sensor for your system.

thermocouple vs RTD Infographic

libmatt.com

libmatt.com