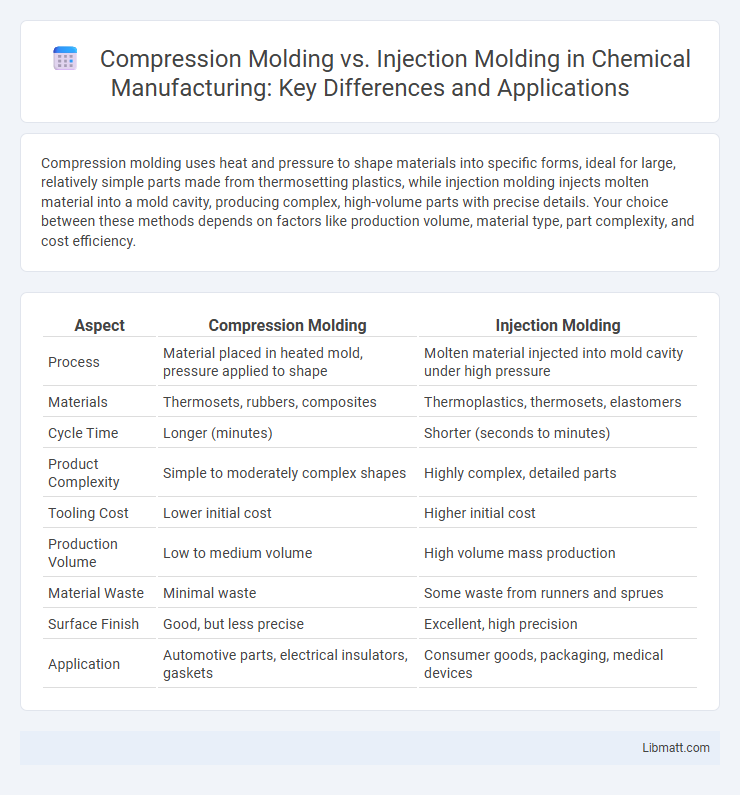

Compression molding uses heat and pressure to shape materials into specific forms, ideal for large, relatively simple parts made from thermosetting plastics, while injection molding injects molten material into a mold cavity, producing complex, high-volume parts with precise details. Your choice between these methods depends on factors like production volume, material type, part complexity, and cost efficiency.

Table of Comparison

| Aspect | Compression Molding | Injection Molding |

|---|---|---|

| Process | Material placed in heated mold, pressure applied to shape | Molten material injected into mold cavity under high pressure |

| Materials | Thermosets, rubbers, composites | Thermoplastics, thermosets, elastomers |

| Cycle Time | Longer (minutes) | Shorter (seconds to minutes) |

| Product Complexity | Simple to moderately complex shapes | Highly complex, detailed parts |

| Tooling Cost | Lower initial cost | Higher initial cost |

| Production Volume | Low to medium volume | High volume mass production |

| Material Waste | Minimal waste | Some waste from runners and sprues |

| Surface Finish | Good, but less precise | Excellent, high precision |

| Application | Automotive parts, electrical insulators, gaskets | Consumer goods, packaging, medical devices |

Introduction to Compression Molding and Injection Molding

Compression molding uses heat and pressure to shape preheated polymer material in a mold, ideal for large, durable parts with complex geometries. Injection molding involves injecting molten plastic into a mold cavity, enabling high-volume production with precise detailing and minimal waste. Understanding these processes helps you choose the best manufacturing method for your product's design and production requirements.

Overview of the Molding Processes

Compression molding involves placing a pre-measured amount of material into a heated mold cavity, applying pressure to shape and cure the part, making it ideal for large, flat, or moderately complex components. Injection molding forces molten material into a mold under high pressure, enabling rapid production of highly detailed and complex parts with tight tolerances. Both processes utilize thermosetting or thermoplastic polymers but differ significantly in cycle time, material waste, and suitability for different production volumes.

Key Differences in Operation

Compression molding involves placing a preheated polymer into an open mold cavity and applying pressure to shape the material, while injection molding injects molten plastic into a closed mold under high pressure. Compression molding is best suited for thermosetting plastics and large, durable parts, whereas injection molding excels with thermoplastics and mass production of intricate, high-precision components. Understanding these key differences in operation helps you select the ideal molding process based on material type, part complexity, and production volume.

Material Compatibility and Selection

Compression molding excels with thermosetting plastics and composites like fiberglass and carbon fiber, offering superior heat resistance and structural integrity. Injection molding is ideally suited for thermoplastics such as ABS, polyethylene, and polystyrene, allowing rapid production of complex, high-precision parts. Understanding your product's material requirements will help determine the optimal molding process for durability and performance.

Quality and Precision of Finished Products

Compression molding delivers consistent quality with excellent surface finish and minimal internal stresses, making it ideal for large, durable parts. Injection molding offers superior precision and tight dimensional tolerances, enabling complex geometries and high-detail features in finished products. Your choice depends on whether you prioritize robust material properties or intricate design accuracy.

Cycle Time and Production Efficiency

Compression molding generally has longer cycle times, typically ranging from 30 seconds to several minutes, making it less efficient for high-volume production. Injection molding offers significantly shorter cycle times, often just a few seconds per part, enabling faster production rates and higher overall efficiency. Your choice between these methods depends on the balance between production speed and material handling requirements.

Cost Analysis: Tooling and Production

Compression molding generally involves lower initial tooling costs compared to injection molding, making it more cost-effective for smaller production runs or simpler parts. Injection molding requires expensive, precision-machined molds but offers faster production cycles and lower per-unit costs at high volumes, ideal for mass production. Your choice should balance the upfront investment against the anticipated production quantity to optimize overall costs.

Common Applications and Industry Use Cases

Compression molding is widely used in automotive manufacturing for producing large, durable parts such as bumpers, fenders, and housings, especially with thermoset plastics and composite materials. Injection molding dominates consumer electronics, medical devices, and packaging industries due to its precision and capability to produce complex, high-volume plastic components. Both techniques find extensive application in aerospace, electrical, and industrial equipment sectors, with compression molding preferred for heat-resistant materials and injection molding favored for intricate geometries.

Environmental Impact and Sustainability

Compression molding generates less material waste and typically uses lower energy compared to injection molding, making it more environmentally friendly for large, simple parts. Injection molding consumes more energy and produces more scrap due to complex tooling and faster cycle times, but it allows for recycling of plastic pellets and supports high-volume production efficiency. Choosing the right process for your product can enhance sustainability by balancing energy use, waste generation, and recyclability.

Choosing the Right Molding Process for Your Project

Selecting between compression molding and injection molding depends on your project's material, complexity, and production volume requirements. Compression molding is ideal for thermosetting polymers, large parts, and lower volumes, offering cost-effective tooling and excellent mechanical properties. Injection molding suits high-volume production of intricate, precise components using thermoplastics, with faster cycle times and minimal post-processing.

Compression molding vs injection molding Infographic

libmatt.com

libmatt.com