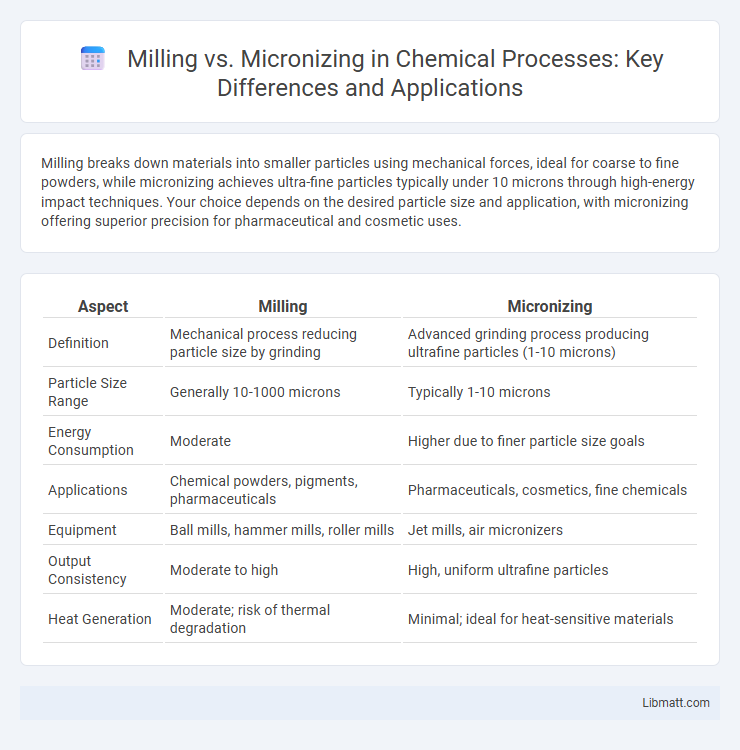

Milling breaks down materials into smaller particles using mechanical forces, ideal for coarse to fine powders, while micronizing achieves ultra-fine particles typically under 10 microns through high-energy impact techniques. Your choice depends on the desired particle size and application, with micronizing offering superior precision for pharmaceutical and cosmetic uses.

Table of Comparison

| Aspect | Milling | Micronizing |

|---|---|---|

| Definition | Mechanical process reducing particle size by grinding | Advanced grinding process producing ultrafine particles (1-10 microns) |

| Particle Size Range | Generally 10-1000 microns | Typically 1-10 microns |

| Energy Consumption | Moderate | Higher due to finer particle size goals |

| Applications | Chemical powders, pigments, pharmaceuticals | Pharmaceuticals, cosmetics, fine chemicals |

| Equipment | Ball mills, hammer mills, roller mills | Jet mills, air micronizers |

| Output Consistency | Moderate to high | High, uniform ultrafine particles |

| Heat Generation | Moderate; risk of thermal degradation | Minimal; ideal for heat-sensitive materials |

Introduction to Milling and Micronizing

Milling and micronizing are advanced particle size reduction techniques used in pharmaceutical, chemical, and food industries to enhance material properties and bioavailability. Milling typically involves mechanical comminution through cutting, grinding, or shearing, whereas micronizing employs jet mills or fluid energy to produce ultra-fine particles in the micron or sub-micron range. Understanding the differences in equipment, energy consumption, and particle size distribution can help you select the optimal process for your specific material and application needs.

Defining Milling: Processes and Applications

Milling involves mechanically breaking down materials into smaller particles using various techniques such as ball milling, roller milling, or hammer milling, optimizing particle size for enhanced surface area and reactivity. It is widely applied in industries ranging from pharmaceuticals to food processing, where particle size uniformity improves product consistency and bioavailability. Understanding milling processes helps you select the appropriate method to achieve desired textures and functional properties for your specific applications.

Micronizing Explained: Techniques and Benefits

Micronizing involves reducing particle sizes to the micron or submicron scale using specialized techniques like jet milling or cryogenic grinding, enhancing material properties such as solubility and bioavailability. This process can improve the texture, dispersibility, and absorption rate of powders compared to traditional milling, which typically achieves coarser particle sizes. Understanding micronizing techniques allows you to optimize product performance in pharmaceuticals, food, and cosmetic applications.

Key Differences Between Milling and Micronizing

Milling involves mechanically breaking down materials into smaller particles using grinding or cutting processes, typically producing particle sizes ranging from 10 to 100 microns. Micronizing refines particles further to a finer scale, often below 10 microns, using advanced techniques like jet milling or cryogenic grinding for enhanced surface area and bioavailability. The key differences lie in particle size precision, equipment complexity, and the resulting material properties influencing dissolution rates and formulation performance.

Particle Size Comparison: Milling vs. Micronizing

Milling typically reduces particle size to the range of 10 to 100 microns, making it suitable for bulk material size reduction. Micronizing achieves significantly finer particles, often below 10 microns, enhancing surface area and solubility for pharmaceutical and chemical applications. The choice between milling and micronizing depends on the required particle size distribution and the material's sensitivity to heat or mechanical stress.

Equipment and Technology Overview

Milling employs mechanical forces using equipment such as ball mills, hammer mills, and jet mills to reduce particle size through impact, attrition, or shear. Micronizing utilizes advanced air classifying mills or fluid energy mills operating at high velocities to achieve ultra-fine particle sizes in the micron and submicron range. The technology in micronizing prioritizes precise particle size distribution and minimal thermal impact, whereas traditional milling equipment often balances size reduction with throughput efficiency.

Material Suitability for Each Process

Milling is ideal for materials with moderate hardness and moisture content, such as grains, spices, and pharmaceuticals, effectively reducing particle size without altering chemical properties. Micronizing suits brittle or crystalline substances like vitamins, minerals, and polymers, delivering ultra-fine particle sizes down to the micrometer scale for enhanced bioavailability or reactivity. Your choice depends on the material's physical characteristics and the desired final particle size, influencing process efficiency and product quality.

Cost Implications: Milling vs. Micronizing

Milling generally incurs lower operational costs compared to micronizing due to simpler equipment requirements and reduced energy consumption. Micronizing demands advanced technology and higher energy input to achieve ultra-fine particle sizes, leading to increased expenses. Your choice between milling and micronizing will impact overall production costs depending on the desired particle size and application precision.

Industry Applications and Use Cases

Milling and micronizing serve distinct industry applications based on particle size requirements and material properties, with milling commonly used in pharmaceuticals, food processing, and chemical production to achieve coarse to fine granules, while micronizing is essential for producing ultra-fine powders in sectors like cosmetics, nanotechnology, and advanced drug delivery systems. Your selection between milling and micronizing influences product performance, bioavailability, and processing efficiency, especially in industries where uniform particle size distribution and enhanced surface area are critical. Both techniques are integral to customizing material characteristics for specific use cases, such as improving solubility in pharmaceuticals or optimizing texture in food products.

Choosing the Right Process for Your Needs

Milling and micronizing are both particle size reduction techniques, but milling typically produces coarser particles, while micronizing achieves ultra-fine particles down to a few microns. Choosing the right process depends on your desired particle size, material properties, and application requirements, such as bioavailability or surface area enhancement. Understanding these key differences ensures optimal performance and efficiency in your production workflow.

Milling vs micronizing Infographic

libmatt.com

libmatt.com