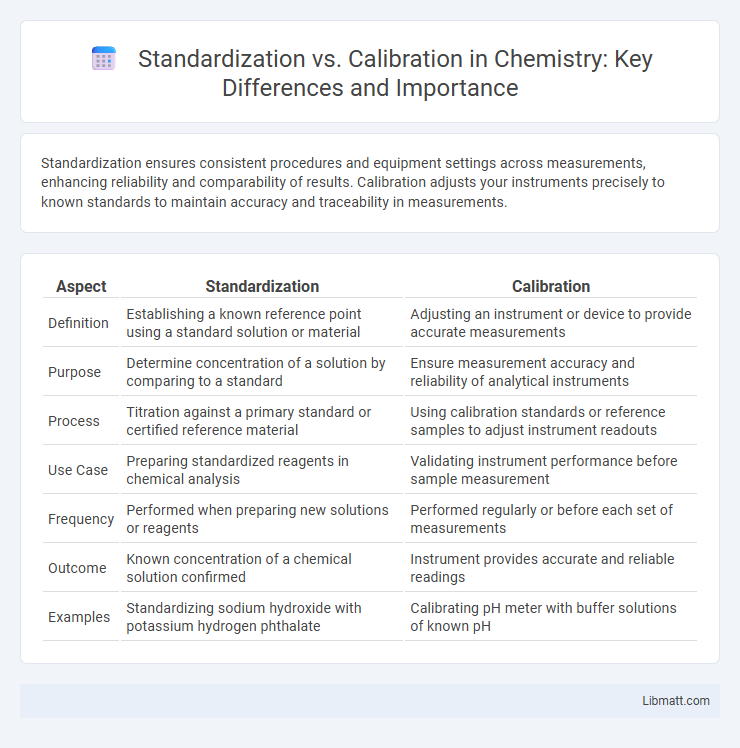

Standardization ensures consistent procedures and equipment settings across measurements, enhancing reliability and comparability of results. Calibration adjusts your instruments precisely to known standards to maintain accuracy and traceability in measurements.

Table of Comparison

| Aspect | Standardization | Calibration |

|---|---|---|

| Definition | Establishing a known reference point using a standard solution or material | Adjusting an instrument or device to provide accurate measurements |

| Purpose | Determine concentration of a solution by comparing to a standard | Ensure measurement accuracy and reliability of analytical instruments |

| Process | Titration against a primary standard or certified reference material | Using calibration standards or reference samples to adjust instrument readouts |

| Use Case | Preparing standardized reagents in chemical analysis | Validating instrument performance before sample measurement |

| Frequency | Performed when preparing new solutions or reagents | Performed regularly or before each set of measurements |

| Outcome | Known concentration of a chemical solution confirmed | Instrument provides accurate and reliable readings |

| Examples | Standardizing sodium hydroxide with potassium hydrogen phthalate | Calibrating pH meter with buffer solutions of known pH |

Understanding Standardization: Definition and Purpose

Standardization refers to establishing consistent protocols, measurements, or procedures to ensure uniformity and comparability across different systems or products. Its purpose is to create a reliable framework that facilitates quality control, interoperability, and regulatory compliance. Understanding standardization helps you maintain consistency in processes, which ultimately enhances efficiency and trust in outcomes.

What is Calibration? Key Concepts Explained

Calibration is the process of adjusting and verifying the accuracy of a measurement instrument by comparing it against a known standard or reference. It ensures that your equipment produces precise and reliable results within specified tolerances, minimizing measurement errors and enhancing data quality. Key concepts include traceability to national standards, use of certified reference materials, and routine interval checks to maintain consistent performance over time.

Differences Between Standardization and Calibration

Standardization establishes a consistent baseline or reference point for measurements using a known standard, ensuring uniformity across processes. Calibration adjusts an instrument or device to align its readings with recognized standards, enhancing accuracy and reliability. Understanding these differences helps you maintain precision in measurement systems and ensures comparability of data.

Importance of Standardization in Quality Control

Standardization ensures consistent measurement results by establishing uniform procedures and reference materials, which is crucial in quality control for maintaining product reliability and compliance with industry regulations. Calibration adjusts instruments to align with standard values, but without standardization, these adjustments lack a common benchmark, potentially leading to variability in production outcomes. Your quality assurance processes benefit significantly from standardization as it provides a reliable foundation for accurate calibration and consistent performance across different batches and equipment.

The Role of Calibration in Measurement Accuracy

Calibration plays a crucial role in ensuring measurement accuracy by adjusting instruments to match known standards, minimizing errors caused by instrument drift or environmental factors. Regular calibration verifies the precision of devices, maintaining consistency and reliability in your measurement results over time. Proper calibration enhances the validity of data, supporting better decision-making and quality control in various technical and scientific applications.

Common Applications of Standardization and Calibration

Standardization and calibration are essential in scientific research, manufacturing, and laboratory testing to ensure accuracy and consistency. Standardization is widely applied in quality control processes to maintain uniformity in product specifications and regulatory compliance. Calibration is crucial in instrument maintenance across industries such as healthcare, automotive, and aerospace to verify and adjust equipment precision against known standards.

Advantages and Limitations of Standardization

Standardization enhances consistency and comparability of results across different laboratories by using uniform protocols and reference materials, which improves data reliability and quality control. However, its limitations include potential inflexibility in adapting to specific sample variations and the risk of overlooking unique experimental conditions that require tailored adjustments. Standardization may also involve significant upfront costs and time investments for training and implementation before realizing its benefits.

Benefits and Challenges of Calibration Processes

Calibration ensures measurement accuracy by comparing instruments against known standards, which enhances reliability and compliance in your operations. The benefits include improved product quality, minimized errors, and increased confidence in data integrity across industries. Challenges involve the need for regular recalibration, technical expertise, and managing calibration costs within tight operational schedules.

Choosing Between Standardization and Calibration: Factors to Consider

Choosing between standardization and calibration depends on the specific measurement needs and accuracy requirements of the process. Standardization ensures consistent results across different instruments and locations by applying uniform procedures, while calibration adjusts equipment to meet established reference standards, ensuring precision and reliability. Factors to consider include the purpose of measurement, frequency of use, regulatory compliance, and the acceptable margin of error.

Best Practices for Effective Standardization and Calibration

Best practices for effective standardization and calibration include using certified reference materials and maintaining consistent environmental conditions to ensure accurate measurements. Regularly scheduled calibration sessions and detailed documentation of procedures help preserve equipment performance and traceability. You should also implement proper training for personnel to minimize variability and optimize measurement reliability.

standardization vs calibration Infographic

libmatt.com

libmatt.com