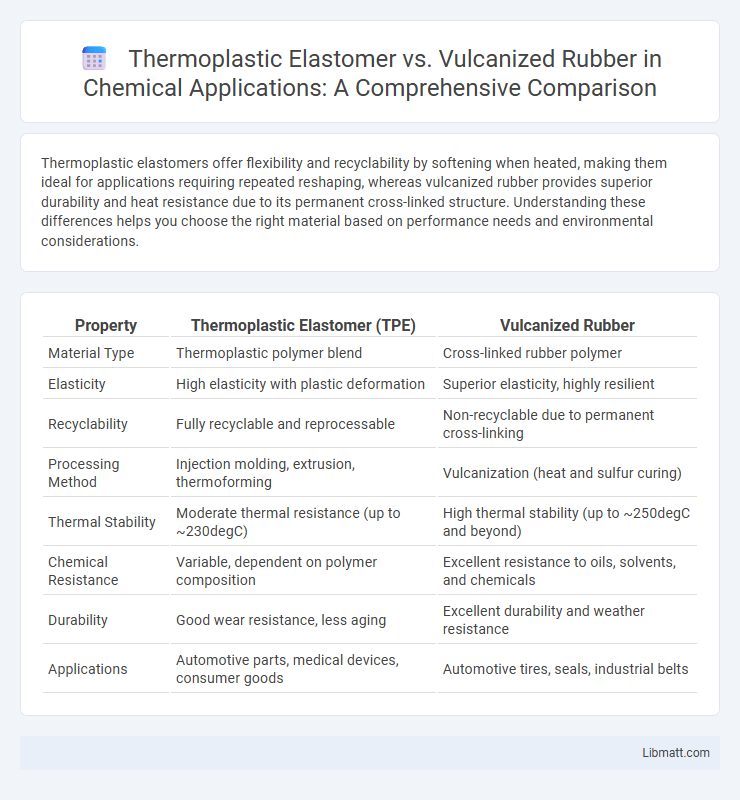

Thermoplastic elastomers offer flexibility and recyclability by softening when heated, making them ideal for applications requiring repeated reshaping, whereas vulcanized rubber provides superior durability and heat resistance due to its permanent cross-linked structure. Understanding these differences helps you choose the right material based on performance needs and environmental considerations.

Table of Comparison

| Property | Thermoplastic Elastomer (TPE) | Vulcanized Rubber |

|---|---|---|

| Material Type | Thermoplastic polymer blend | Cross-linked rubber polymer |

| Elasticity | High elasticity with plastic deformation | Superior elasticity, highly resilient |

| Recyclability | Fully recyclable and reprocessable | Non-recyclable due to permanent cross-linking |

| Processing Method | Injection molding, extrusion, thermoforming | Vulcanization (heat and sulfur curing) |

| Thermal Stability | Moderate thermal resistance (up to ~230degC) | High thermal stability (up to ~250degC and beyond) |

| Chemical Resistance | Variable, dependent on polymer composition | Excellent resistance to oils, solvents, and chemicals |

| Durability | Good wear resistance, less aging | Excellent durability and weather resistance |

| Applications | Automotive parts, medical devices, consumer goods | Automotive tires, seals, industrial belts |

Introduction to Thermoplastic Elastomers and Vulcanized Rubber

Thermoplastic elastomers (TPEs) combine the elastic properties of rubber with the processing advantages of thermoplastics, allowing them to be melted and reshaped multiple times without significant degradation. Vulcanized rubber is a chemically cross-linked material created by adding sulfur or other curatives to natural or synthetic rubber, resulting in enhanced strength, elasticity, and thermal stability. TPEs offer recyclability and ease of manufacturing, whereas vulcanized rubber provides superior durability and resistance in high-stress applications.

Chemical Composition and Structure Differences

Thermoplastic elastomers (TPEs) consist of block copolymers combining hard thermoplastic segments and soft elastomeric segments, enabling reversible physical cross-linking without chemical reactions. Vulcanized rubber is chemically cross-linked through sulfur or other agents, creating permanent covalent bonds that enhance elasticity and heat resistance. The molecular structure of TPEs allows them to be melted and reprocessed, while vulcanized rubber's irreversible cross-links result in a thermoset network with fixed mechanical properties.

Manufacturing Processes: TPE vs Vulcanization

Thermoplastic elastomers (TPE) are produced through melting and molding processes such as injection molding or extrusion, allowing for easy recyclability and faster manufacturing cycles. Vulcanized rubber requires a chemical curing process where sulfur cross-links polymer chains under heat and pressure, resulting in permanent elastic properties and enhanced durability. Your choice between TPE and vulcanized rubber depends on the desired balance between manufacturing efficiency and material performance.

Mechanical and Physical Properties Comparison

Thermoplastic elastomers exhibit remarkable flexibility and resilience similar to vulcanized rubber but offer superior processability due to their ability to be melted and reshaped, unlike vulcanized rubber's permanent cross-linked structure. Vulcanized rubber generally demonstrates higher tensile strength, better abrasion resistance, and more stable mechanical properties across a wide temperature range, making it ideal for heavy-duty applications. Thermoplastic elastomers provide enhanced recyclability and lower density, contributing to lighter, more sustainable products, though with slightly reduced elasticity and temperature resistance compared to vulcanized rubber.

Flexibility and Elasticity: Which Material Performs Better?

Thermoplastic elastomers (TPEs) offer superior flexibility due to their ability to stretch and return to their original shape without permanent deformation, making them ideal for applications requiring repeated bending. Vulcanized rubber excels in elasticity because of its cross-linked polymer chains formed through vulcanization, providing enhanced resilience and long-term durability under stress. While TPEs provide easier processing and recycling, vulcanized rubber outperforms in maintaining elasticity under harsh environmental conditions.

Environmental Impact and Sustainability

Thermoplastic elastomers (TPEs) offer a more sustainable alternative to vulcanized rubber due to their recyclability and lower energy consumption during processing. Vulcanized rubber, being cross-linked, is difficult to recycle, leading to higher landfill waste and environmental pollution. Your choice of TPE can reduce carbon footprint and support circular economy initiatives in material manufacturing.

Cost Efficiency and Economic Considerations

Thermoplastic elastomers (TPEs) offer superior cost efficiency compared to vulcanized rubber due to their easier processing and recyclability, which reduces waste and lowers production expenses. Vulcanized rubber requires longer curing times and more energy-intensive processes, leading to higher manufacturing costs and limited material reuse. Your choice between TPEs and vulcanized rubber should consider these economic factors alongside performance requirements for optimized budget management.

Common Applications in Industry

Thermoplastic elastomers (TPEs) are widely utilized in automotive interior components, medical device tubing, and flexible consumer goods due to their recyclability and ease of processing. Vulcanized rubber remains dominant in heavy-duty applications such as industrial conveyor belts, tires, and seals because of its superior durability and resistance to heat and mechanical stress. Both materials serve critical roles in manufacturing, with TPEs favored for lightweight, cost-effective solutions and vulcanized rubber preferred for high-performance, long-lasting products.

Durability, Lifespan, and Maintenance

Thermoplastic elastomers (TPE) offer excellent durability with resistance to wear, chemicals, and UV exposure, resulting in a longer lifespan compared to vulcanized rubber. Vulcanized rubber, while robust and heat-resistant due to its cross-linked structure, often requires more maintenance to prevent cracking and degradation over time. For your applications demanding minimal upkeep and extended service life, TPE provides a cost-effective, low-maintenance solution.

Conclusion: Choosing Between Thermoplastic Elastomer and Vulcanized Rubber

Thermoplastic elastomers offer superior processability and recyclability, making them ideal for applications requiring flexibility and easy manufacturing. Vulcanized rubber provides enhanced durability, heat resistance, and better performance under extreme conditions, suited for heavy-duty uses. Your choice between thermoplastic elastomer and vulcanized rubber depends on the specific demands of your project, balancing flexibility, durability, and environmental impact.

Thermoplastic elastomer vs vulcanized rubber Infographic

libmatt.com

libmatt.com